MetalProcessing Laser Solutions

Laser Solutions for Metal Processing

Metal processing isn’t just about shaping material; it’s about hitting tolerances and maintaining throughput. Metal Processing Laser Solutions are designed for exactly that—whether you are cutting complex geometries, welding thin-walled enclosures, cleaning oxides before coating, or marking serial numbers for traceability. Traditional mechanical methods often create bottlenecks. The value is simple: we replace brute force with precision light to boost batch consistency, eliminate secondary manual grinding, and drastically reduce the cost of rework.

In the automotive and auto parts industry, lasers are not adopted to look “advanced”—they’re used to make mass production consistent, traceability reliable, and assembly quality repeatable. OEMs and suppliers typically struggle with three costly problems: unreadable codes that break traceability, unstable welds that increase rework and quality variation, and inconsistent surface conditions that cause coating, bonding, or welding defects. A practical laser solution focuses on reducing these uncertainties so every batch meets the same standard.

Common Challenges in Metal Processing

If your shop floor struggles with these issues, our solutions are designed to fix them:

- Secondary Processing: Cutting leaves heavy burrs or dross, requiring manual deburring before assembly.

- Weld Distortion: Thin sheet metal warps due to high heat input from TIG/MIG, ruining dimensional accuracy.

- Inconsistent Surface: Rust, oil, or oxide layers cause weld porosity or paint peeling downstream.

- Material Sensitivity: Struggling to switch parameters between Stainless Steel, Aluminum, and Copper without trial-and-error.

- Traceability Gaps: Printed labels fall off, or shallow marks get covered by paint, losing track of batches.

Typical Materials & Workpieces

Materials:

- Stainless Steel (304, 316)

- Carbon Steel (Mild Steel)

- Aluminum (6061, 5052)

- Copper & Brass (High reflectivity)

- Galvanized Steel

Workpieces:

- Sheet metal assemblies and brackets

- Electronic enclosures and chassis

- Tubular frames and structural pipes

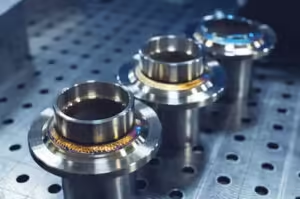

- Machined plates and flanges

Surface Conditions:

- Handling: Rust, mill scale, oxidation, grease/oil contamination.

Goals: What You’re Trying to Achieve

- Clean Cutting Edges: Burr-free cuts with tight tolerances, ready for immediate welding or assembly.

- Stable Seams: High-strength welds with low thermal distortion and minimal post-weld cleanup.

- Surface Prep: Virgin surface quality to ensure perfect adhesion for coatings or welding.

- Permanent Identification: Deep, high-contrast markings that remain readable throughout the product lifecycle.

Recommended Process Paths

1. Laser Cutting Path

- Best For: Sheet metal fabrication, brackets, fixtures, and rapid prototyping.

- The Process: Focused high-power beams vaporize metal with nitrogen/oxygen assist gas.

- The Output: Square edges, no tool wear, and the ability to cut complex nests to minimize scrap.

2 Laser Welding Path

- Best For: Thin-walled enclosures, battery packs, and aesthetic structural parts.

- The Process: “Wobble” head technology stirs the weld pool for better gap bridging without overheating the part.

- The Output: Hermetic seals, consistent bead appearance, and significantly reduced thermal deformation.

3 Laser Cleaning Path

- Best For: Removing rust, stripping paint, or cleaning oxides before welding/coating.

- The Process: High-peak-power pulses ablate contaminants without damaging the base metal.

- The Output: A chemically clean surface with consistent surface energy for reliable bonding.

4 Laser Marking / Dot Peen Path

- Best For: Part identification, QR/DataMatrix codes, and logo branding.

- The Process: Annealing (black mark) or engraving (material removal) based on durability needs.

- The Output: Permanent traceability that survives abrasion, heat, and chemicals.

Equipment Needed for Metal Processing

To achieve these results, you need the right tool for the job:

- Fiber Laser Cutting Machines: For precision geometry and speed.

- Laser Welding Machines: Handheld for flexibility or automated for volume.

- Laser Cleaning Machines: Pulse lasers for mold/part cleaning.

- Laser Marking Machines: Fiber/MOPA/UV sources for coding.

- Electric Dot Peen Marking Machines: (Optional) For deep marking on rough castings or high-wear heavy machinery.

How to Choose the Right Setup

Don’t just buy “watts”; buy the configuration that fits your workflow.

1 Production Volume & Cycle Time

- Prototype/Job Shop: Handheld or open-table systems offer the fastest changeover between diverse jobs.

- High Volume: Enclosed, automated systems with rotary tables or conveyor integration are required to hit strict Takt times.

2 Material & Thickness Sensitivity

- Reflective Metals: Copper and Aluminum require sources with back-reflection protection.

- Heat Sensitivity: Thin medical parts need pulsed lasers (MOPA/UV) to prevent discoloration; structural steel needs Continuous Wave (CW) power.

3 Workstation Type

- Handheld: Maximum mobility for large parts that can’t be moved easily.

- Desktop/Stationary: Best for small parts requiring high precision.

- Inline: Integrated directly into your PLC-controlled assembly line.

4 Fixturing & Consistency

- The Golden Rule: A laser is only as accurate as the fixture holding the part. If your part moves, the laser misses. Invest in rigid, repeatable tooling over higher laser power.

Quality Control & Acceptance Tips

- Cutting: Inspect for dross on the bottom edge and check perpendicularity.

- Welding: Verify penetration depth and check for cracks or porosity (visual or cross-section).

- Cleaning: Perform a “Water Break Test”—water should sheet off, not bead up, indicating a clean surface.

- Marking: Verify Grade A/B readability with a standard barcode verifier.

Downloads for Metal Processing

- [PDF] Metal Processing Application Guide

- [Checklist] Process Selection & Fixturing Guide

- [Reference] Laser Marking Sample Gallery (SS/Al/Brass)

- [Data Sheet] Starter Parameters (Cut/Weld/Clean)

- [Guide] Daily Maintenance Checklist

Stop Guessing. Validate Your Process. Don’t rely on specs alone. Send us your drawings or physical parts. We will run a feasibility test, calculate your cycle time, and provide a process report proving the cost-savings.

[ Upload Project Details & Request Sample Testing ]

Best value laser equipment for Metal Processing

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

Metal Processing news and the latest application solutions

تنزيل الموارد

Process Parameters & Speed Charts

ملف PDF • 5.2 ميجابايت

Application & Configuration Guides

ملف PDF • 5.2 ميجابايت

Sample Libraries

ملف PDF • 5.2 ميجابايت