Soldadura tradicional y soldadura láser: ¿Qué método predomina para su proyecto?

In the world of manufacturing and metalworking, the debate between traditional welding and laser welding has gained significant traction in recent years. As technology continues to evolve, industries are increasingly shifting towards more efficient, precise, and cost-effective welding methods. While traditional welding has long been a mainstay in the industry, laser welding is emerging as a game-changer, especially in high-precision applications. In this article, we’ll delve into the key differences between traditional welding and laser welding, highlighting their respective advantages and disadvantages, and examining where each technique excels in various industrial settings.

Tabla de contenido

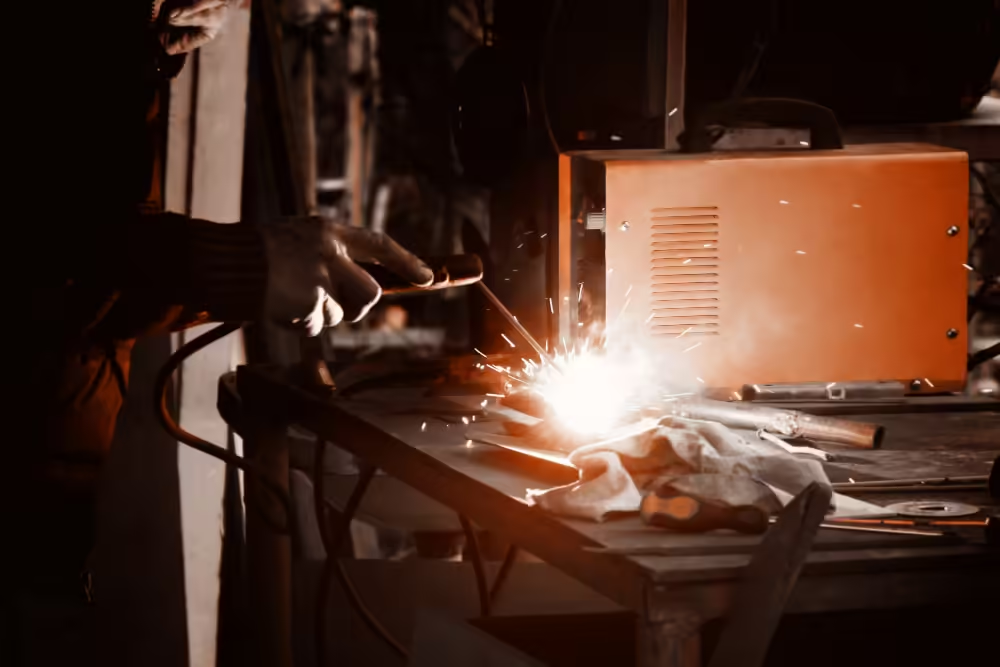

¿Qué es la soldadura tradicional?

Traditional welding encompasses a variety of techniques, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), Stick welding, and Arc welding. These methods have been around for decades and are widely used in industries ranging from construction to automotive manufacturing. The basic process of traditional welding involves generating intense heat to melt and fuse metals together, often with the addition of a filler material to help join the surfaces.

One of the key advantages of traditional welding is its versatility. It can be used on a wide variety of metals and thicknesses, from thin sheets to thick plates. The tools are generally more affordable, and the process itself is relatively simple to set up. This makes traditional welding an attractive option for large-scale industrial projects, especially in situations where high-speed production is not critical.

Advantages of Traditional Welding:

- Cost-Effective: Traditional welding equipment tends to be cheaper upfront and requires less specialized training.

- Versatilidad: Can handle a wide range of materials and thicknesses, making it ideal for various industries.

- Established Process: Well-understood and widely used, with years of development in different welding techniques.

Disadvantages of Traditional Welding:

- Lower Precision: Traditional welding methods often result in larger heat-affected zones and can cause warping or distortion in the material being welded.

- Slower Speed: These methods generally take longer to complete, especially on intricate or small parts.

- Increased Maintenance: Traditional welding tools may require more frequent maintenance and upkeep.

¿Qué es la soldadura láser?

Laser welding, on the other hand, is a modern welding technique that uses focused laser beams to melt and fuse metal parts together. The laser beam is highly concentrated and can be precisely controlled, which allows for fine, accurate welds with minimal heat distortion. Unlike traditional welding, laser welding doesn’t require filler material in many applications, and it is capable of producing strong, clean welds even in challenging, tight spaces.

With the rapid advancements in laser technology, laser welding has quickly become the method of choice for many industries, especially where high precision is required, such as electronics, aerospace, and automotive manufacturing. The ability to work with a variety of materials—including metals that are difficult to weld with traditional methods—has helped laser welding gain a strong foothold in the market.

Advantages of Laser Welding:

- Alta precisión: The focused laser beam creates clean, strong welds with minimal distortion, making it ideal for small, intricate parts.

- Faster Speed: Laser welding is typically faster than traditional welding, which increases overall productivity.

- Smaller Heat-Affected Zone (HAZ): Because the laser beam is so focused, it reduces the heat zone, minimizing material stress and preventing unwanted deformation.

- Reduced Post-Welding Work: Less need for cleanup or post-weld treatment due to the precision of the weld.

- Eficiencia energética: Laser welding typically uses less energy compared to traditional welding methods.

Disadvantages of Laser Welding:

- Higher Initial Costs: The equipment for laser welding is more expensive than traditional welding equipment, making the upfront investment higher.

- Training and Expertise: Laser welding requires more technical expertise and skilled operators to manage the equipment effectively.

Comparación entre la soldadura tradicional y la soldadura láser

Precisión y calidad

One of the main differences between traditional welding and laser welding is the precision with which each can work. Traditional welding methods are generally slower and less precise, which can lead to issues like weld distortion, spatter, and imperfections in the joint. Laser welding, on the other hand, produces precise, clean, and strong welds, particularly in applications where quality is paramount.

For example, industries that require tiny, delicate welds—such as electronics or aerospace—will benefit from laser welding’s ability to achieve pinpoint accuracy. Traditional welding, while effective for larger and more general welding tasks, may not be suitable for applications that demand such fine detail.

Speed and Efficiency

When comparing traditional welding and laser welding, laser welding generally wins in terms of speed. The focused laser beam allows for faster welding with a reduced heat-affected zone, meaning parts can be processed more quickly. In contrast, traditional welding requires more time to heat and melt the material, which can slow down the production process, especially in high-volume manufacturing.

Traditional welding and laser welding each have their advantages, but laser welding’s ability to produce fast, accurate welds has made it the go-to option for industries requiring quick turnaround times without sacrificing quality. While traditional welding is often preferred for heavier, large-scale applications, laser welding offers unmatched precision and efficiency, making it the ideal choice for projects that demand both speed and high-quality results.

Costo

Comparing traditional welding and laser welding, while the initial investment in laser welding equipment is typically higher, it can lead to significant long-term savings for projects with high production rates and precise requirements. Laser welding improves efficiency, shortens turnaround times, and reduces material waste, making it a cost-effective option in the long run. In contrast, traditional welding is more cost-effective for smaller-scale operations or projects with tight budgets, due to its lower equipment costs and simpler setup. The decision between traditional and laser welding ultimately depends on the project’s scale and specific needs.

Rango de aplicación: Soldadura tradicional y soldadura láser

Comparing traditional welding and laser welding, both techniques have their specific advantages across various industries. Traditional welding is widely used for heavy-duty applications like shipbuilding, construction, and large-scale manufacturing, where the emphasis is on speed and strength rather than precision. On the other hand, laser welding shines in sectors that require high-quality, fine, and precise welds, such as electronics, medical device manufacturing, and aerospace.

In general, laser welding is ideal for applications where space is limited and precision is critical, while traditional welding remains more suitable for larger, less intricate parts where speed and strength take priority.

¿Cuál es mejor para su proyecto?

Ultimately, choosing between traditional welding and laser welding comes down to your project’s specific needs. If precision, speed, and minimal distortion are your top priorities, laser welding is likely the better choice. On the other hand, if you’re working with heavy materials or large-scale projects where cost is a concern, traditional welding may be more suitable.

Conclusión

While both traditional welding and laser welding have their strengths and weaknesses, laser welding has proven to be a more efficient, precise, and versatile option in many modern industrial applications. Laser welding offers high-quality, fast, and accurate results, making it an ideal choice for projects that require both speed and precision. On the other hand, traditional welding continues to hold a significant place in heavy-duty manufacturing, where the need for speed and strength outweighs the demand for high precision.

When it comes to costs, laser welding may require a higher initial investment, but its long-term savings in labor and material efficiency often make it a more cost-effective solution. Ultimately, the choice between traditional welding and laser welding depends on the specific requirements of each project.