Soldadura de acero inoxidable: exploración de las aplicaciones y beneficios de la tecnología de soldadura de acero inoxidable

Tabla de contenido

As one of the core processes in modern manufacturing, stainless steel welding plays an indispensable role in key sectors such as construction, shipbuilding, food processing, and automotive manufacturing. With continuous innovation in welding technology and materials, this process is advancing toward greater efficiency, precision, and stability.

Stainless steel, known for its high corrosion resistance, excellent strength, and attractive appearance, has become an integral part of both industrial and everyday life. The welding of stainless steel is a technically demanding process that requires high precision. Welding stainless steel not only requires strong weld joints but also ensures excellent appearance and corrosion resistance.

Technical Challenges and Solutions in Stainless Steel Welding

One of the main challenges in stainless steel welding is controlling heat input. Due to stainless steel’s poor thermal conductivity, excessive welding heat can lead to distortion and even damage to the weld joint structure. Additionally, stainless steel tends to form an oxide layer during welding, which affects the appearance and weld quality.

By choosing the appropriate welding methods such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, these issues can be effectively controlled. TIG welding is particularly suitable for welding thin-walled stainless steel, providing high precision and minimal heat-affected zones. MIG welding, on the other hand, is more efficient for welding thicker stainless steel materials.

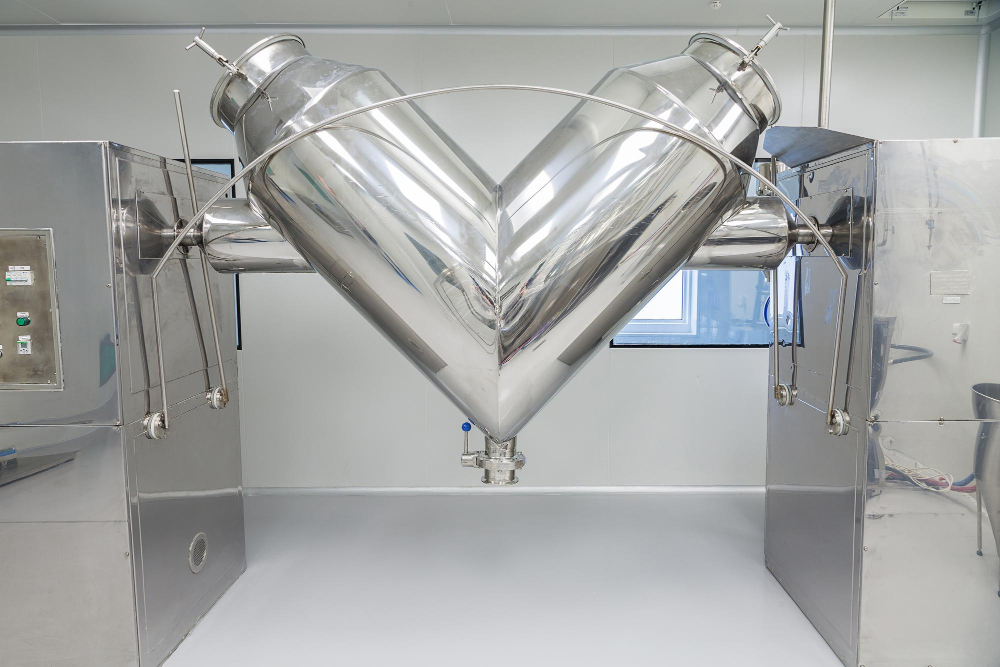

Case Study 1: Stainless Steel Welding in Food Processing Equipment

In the food processing industry, the welding of stainless steel is essential for manufacturing equipment that meets strict hygiene and safety standards, thanks to the material’s inherent corrosion resistance and ease of cleaning. The quality of this welding process is therefore critical in such applications.

For example, a food processing plant used stainless steel welding to manufacture a large mixing machine that met hygiene requirements. By adopting precise TIG welding methods, the strength and hygiene requirements of the weld joint were ensured, avoiding the formation of oxide layers and porosity on the stainless steel surface, successfully meeting industry standards.

Case Study 2: Stainless Steel Welding in Building Structures

Stainless steel welding is extensively employed in the construction sector, particularly for high-rise buildings and bridges, where it ensures both structural strength and long-term durability due to the material’s excellent corrosion resistance.

For instance, in the construction of a bridge, stainless steel welding was employed to join structural steel components. This not only enhanced the structural stability but also lowered maintenance costs, as the durability and corrosion resistance of the welds significantly extended the bridge’s service life.

The Advantages and Technology Choices in Stainless Steel Welding

1.High Strength and Corrosion Resistance: Stainless steel itself has very high strength and corrosion resistance, making its welded joints strong and durable. This makes stainless steel welding widely used in industries with high requirements for material strength and corrosion resistance, such as aerospace and shipbuilding.

2.Aesthetic Finish: Welded joints in stainless steel are characterized by their smoothness, achieved through precise control during the welding process, which results in a visually clean and appealing appearance. In particular, TIG welding enables highly accurate welding with superior surface quality.

3.Wide Application Range: Stainless steel welding is widely applied in various industries, including automotive manufacturing, medical equipment, construction, and food processing. Different welding methods can be chosen based on specific requirements, adapting to different material thicknesses and types.

The Future of Stainless Steel Welding

With ongoing technological advances, the future of stainless steel welding appears highly promising. The adoption of automated welding systems and the growing use of welding robotics are expected to significantly enhance efficiency, increase production throughput, and reduce human error.

As environmental regulations become stricter, there is a growing emphasis on developing welding methods that produce less heat and pollution. Laser welding, known for its high efficiency and minimal environmental impact, is increasingly being adopted for stainless steel applications. Looking ahead, we can expect this technology to make significant advancements, achieving new levels of precision, efficiency, and sustainability.

Conclusión

As an indispensable technology in modern manufacturing and construction, stainless steel welding plays a vital role in applications ranging from food processing equipment to architectural structures and other high-demand industrial sectors. With ongoing advancements in welding technology, this process is continuously evolving to become more precise, efficient, and better equipped to meet the stringent standards required across diverse industries.