Titanium Welding Challenges and How to Prevent Contamination

جدول المحتويات

Titanium Welding requires strict atmospheric control. When using a handheld laser system, inadequate shielding or poor surface cleaning can rapidly cause oxidation and weld contamination.

Why shielding matters in Titanium Welding

Titanium becomes reactive above ~550°C; oxygen, nitrogen and hydrogen can form oxides, nitrides and hydrides that embrittle the fusion zone. For handheld laser work this means a focused shielding approach is essential. Guidance on using high-purity argon and proper back-purging is well established in industry practice.

- Use 100% argon or approved argon/helium mixes when recommended.

- Specify gas purity (often 99.998% or better) and low dew point to reduce oxygen and moisture.

- Maintain pre-flow and post-flow times long enough to protect the molten pool until it cools below the reactive temperature.

Cleaning and fit-up for clean Titanium Welding

Contaminants on the surface are fast routes to weld failure. Remove machining oils, fingerprints, cutting fluids, and alpha case before attempting a weld.

Mechanical cleaning: non-ferrous brushes, approved abrasive media (avoid iron contaminants).

Chemical descaling/pickling: follow standardized procedures for titanium surface preparation.

Short, repeatable steps make cleaning routine and auditable:

1.Degrease with an appropriate solvent.

2.Mechanically remove gross oxides with titanium-safe abrasives.

3.Apply chemical pickling only per standard procedures and neutralize thoroughly.

4.Store cleaned parts in a dry, inert environment until welding.

Shielding strategies for handheld laser Titanium Welding

Handheld laser welding adds mobility but reduces the passive protection offered by fixtures. Use physical shrouds, nozzles and purge techniques to create a local inert envelope.

- Local shroud/nozzle: choose designs that provide laminar argon coverage and minimize turbulence.

- Back-purging: for closed sections, use purge dams or internal purge lines to protect the root.

- Enclosures: when feasible, perform laser welds inside a tented purge chamber for the most consistent results. Guidance from industry research supports these active measures to limit atmospheric incursion during laser welding operations.

Common contamination modes and detection during handheld runs

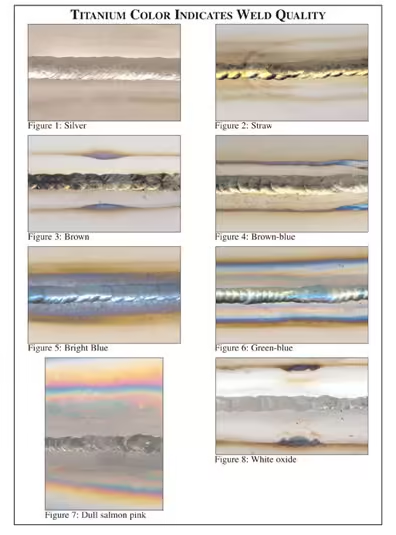

Porosity, gray/black oxide discoloration and sudden changes in bead wetting indicate contamination. If a weld displays a matte gray or dark golden zone, stop and evaluate the shielding and cleanliness; these colors often correlate with nitrogen or oxygen pickup.

Recent laser-welding research reinforces the importance of inert gas choice and flow geometry to reduce atmospheric reaction products in the bead.

Practical checklist for shop implementation (handheld laser focus)

Keep actions short and repeatable — this helps teams consistently avoid contamination.

- Pre-weld: degrease, grit-blast with approved media, and verify no iron contamination.

- Gas setup: verify purity, flow rate, and pre/post flow timing on every weld station.

- Fixtures: use lightweight dams, purge bags or simple inflatable sealing where back-purge is required.

- Trial weld: always perform a short test weld on scrap and inspect for color and porosity before committing to production.

- Record keeping: log gas batch, dew point, and operator sign-off for critical welds.

why these controls matter

When contaminated, the weld zone may form brittle intermetallics or alpha case that reduce fatigue life. Lab and materials references explain the high reactivity of titanium at welding temperatures and why strict shielding and cleaning are non-negotiable.

Post-weld handling and inspection

- Allow an inert post-flow until the bead temperature drops below the reactive threshold.

- Inspect visually and with NDT appropriate to the application (dye penetrant, radiography or ultrasonic as specified).

- If contamination is suspected, remove and rework the weld; do not rely on coatings or post-treatments to mask embrittlement.

Quick summary — operators’ 60-second rule

Before you press the trigger on a handheld laser, run through this 60-second check: clean surface ✓, argon purity and flow ✓, back-purge or shroud in place ✓, test weld color ✓. If any item fails, correct it before proceeding.

Key Takeaways

Titanium Welding is not inherently difficult, but it is unforgiving. The material’s affinity for oxygen, nitrogen, and hydrogen means that small lapses in shielding or surface preparation can permanently affect weld integrity.

In handheld laser applications, success depends less on power settings and more on process discipline. Clean base material. Stable and high-purity shielding gas. Controlled purge environments. Verified pre- and post-flow protection. These are not optional steps — they are structural safeguards against embrittlement and surface contamination.

Operators who treat Titanium Welding as a contamination-control process rather than simply a joining operation consistently achieve cleaner bead profiles, lower porosity rates, and more predictable mechanical performance.

If atmospheric exposure is minimized and procedures are standardized, handheld laser systems can produce repeatable, high-quality titanium welds suitable for demanding industrial applications.

In titanium fabrication, precision is not only about laser focus — it is about environmental control.

For more information on Titanium Welding, please click here.