Laser Solutions for Electronics & Electrical Manufacturing

Electronics & Electrical Laser Solutions

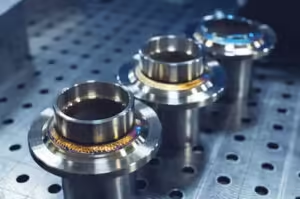

Electronics and electrical manufacturing demands fine detail, tight tolerances, and repeatable quality—often on small parts, mixed materials, and high-volume lines. Laser equipment is used here not for “show,” but to keep outputs stable across batches while protecting delicate surfaces and reducing manual variability.

ل traceability and branding, laser marking creates permanent serial numbers, QR/DataMatrix codes, logos, and spec labels on metal and selected coated surfaces. The advantage is clear readability, clean edges, and consistent results—especially important for quality control and after-sales tracking.

ل joining and assembly, laser welding supports precise energy control for small metal parts and assemblies where appearance, stability, and repeatability matter. In scenarios that are sensitive to heat input, a controlled laser process helps reduce distortion and rework compared with less controlled joining methods.

ل surface preparation and defect reduction, laser cleaning removes oxidation, residue layers, and surface contaminants that can interfere with conductivity, bonding, or subsequent coating processes. A cleaner, more consistent surface improves process stability downstream—especially when your yield depends on small margins.

ل precision cutting needs, laser cutting can support tooling, thin sheet components, and specific electrical-related metal/non-metal cutting tasks where clean edges and accuracy are required, helping shorten iteration cycles and improve fit consistency.

Recommended laser products used in Electronics & Electrical

- آلة الوسم بالليزر – fine, permanent part identification (serial/QR/logo)

- آلة اللحام بالليزر – precise joining for small parts/assemblies with repeatable results

- آلة تنظيف بالليزر – oxidation/residue removal to stabilize downstream processes

- آلة القطع بالليزر – precision cutting for fixtures, thin sheets, and related components

- Electric Dot Peen Marking Machine (optional) – durable marking for rugged metal housings or heavy-duty electrical components (when extreme abrasion resistance is needed)

High-Precision Laser Equipment for Electronics & Electrical

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

Electronics & Electrical News & Latest Application Solutions

تنزيل الموارد

Electronics & Electrical Application Guide

ملف PDF • 5.2 ميجابايت

Process Selection Checklist

ملف PDF • 5.2 ميجابايت

Marking Sample Reference

ملف PDF • 5.2 ميجابايت