MetalProcessing Laser Solutions

Industry solutions for Automotive & Auto Parts Lase

In the automotive and auto parts industry, lasers are not adopted to look “advanced”—they’re used to make mass production consistent, traceability reliable, and assembly quality repeatable. OEMs and suppliers typically struggle with three costly problems: unreadable codes that break traceability, unstable welds that increase rework and quality variation, and inconsistent surface conditions that cause coating, bonding, or welding defects. A practical laser solution focuses on reducing these uncertainties so every batch meets the same standard.

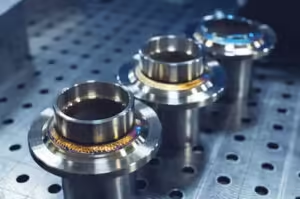

ل part identification and traceability, components often require permanent serial numbers, batch codes, DataMatrix/QR codes, and logos. These marks must stay readable under abrasion, oil, and long service cycles—and ideally connect to internal tracking systems. A آلة الوسم بالليزر is the primary solution for producing high-contrast, repeatable marks with stable positioning. For chassis parts, rough surfaces, or harsh environments where maximum durability is required, an Electric Dot Peen Marking Machine can be added to create deeper, impact-based marks that remain readable even after heavy wear.

ل assembly and joining, many automotive components—brackets, housings, structural parts, and selected EV-related assemblies—demand stable seam quality and tight takt time. A آلة اللحام بالليزر helps achieve consistent weld appearance and quality by controlling heat input more precisely, often reducing distortion and minimizing secondary finishing. In thin-sheet applications or stations with strict cycle-time requirements, laser welding becomes especially valuable—provided the fixturing and process parameters are standardized. In real factories, inconsistent results are often caused less by the machine and more by poor positioning and uncontrolled process conditions.

ل surface preparation before welding, coating, or bonding, automotive production frequently involves oxide layers, rust, paint, and residual oils that destabilize downstream processes. A آلة تنظيف بالليزر offers controlled removal of rust, paint, oxide layers, and contaminants, helping improve weld stability and coating adhesion while reducing rework. This step is often the most overlooked upgrade: many “welding problems” originate from inconsistent surface conditions upstream.

Finally, for tooling, fixtures, and thin sheet processing, suppliers may need fast iteration for jigs, brackets, prototypes, or edge trimming. A آلة القطع بالليزر supports precise cutting for sample development and fixture manufacturing, shortening lead times and improving fit during assembly. Cutting may not be the core process for every automotive line, but it can significantly accelerate prototyping and tooling workflows.

Laser products typically used in Automotive & Auto Parts solutions

- آلة الوسم بالليزر – permanent traceability codes (serial/QR/DataMatrix/logo)

- Electric Dot Peen Marking Machine – extra-durable marking for harsh, high-wear parts

- آلة اللحام بالليزر – stable seams, controlled heat input, reduced rework and distortion

- آلة تنظيف بالليزر – pre-weld/pre-coating surface preparation; rust/paint/oxide removal

- آلة القطع بالليزر – fixture/tooling, prototyping, thin sheet cutting and trimming (as needed)

Best value laser equipment for Automotive & Auto Parts

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

آلة الوسم بالليزر

Automotive & auto parts news and the latest application solutions

تنزيل الموارد

Automotive application guide

ملف PDF • 5.2 ميجابايت

Process selection checklist

ملف PDF • 5.2 ميجابايت

Maintenance quick guide

ملف PDF • 5.2 ميجابايت