كيفية استخدام ماكينة اللحام بالليزر المحمولة بفعالية: دليل شامل

ال Handheld Laser Welding Machine is a game-changing tool in the welding industry, designed for precision, portability, and efficiency. Unlike traditional welding methods that require bulky equipment and complex setups, handheld laser welders are lightweight and portable, allowing them to be used in a wide range of applications. This machine uses a focused laser beam to melt materials at a specific point, creating a strong bond between parts with minimal heat distortion.

Because of their ability to weld a wide variety of materials—such as steel, aluminum, and titanium—without the need for filler materials, handheld اللحام بالليزر machines have become indispensable in industries requiring high-quality welds, including automotive, aerospace, and electronics.

How Does a Handheld Laser Welding Machine Work?

أ Handheld Laser Welding Machine operates by directing a high-powered laser beam to a material, which causes the material to melt and bond together. The beam is transmitted through a fiber optic cable, which focuses the beam onto the material’s surface. The result is a precise, clean weld that minimizes heat distortion and the need for extensive post-welding cleanup.

This machine offers several advantages over traditional methods:

- Precise Heat Control: The focused laser only heats the area being welded, resulting in less damage to surrounding areas.

- Minimal Heat-Affected Zone (HAZ): This reduces the risk of warping or distortion of the material.

- No Need for Filler Materials: Laser welding often doesn’t require additional filler material, making it cost-effective and efficient.

Step-by-Step Guide to Using a Handheld Laser Welding Machine

For beginners, using a Handheld Laser Welding Machine can seem intimidating, but by following these detailed steps, you’ll gain confidence and get familiar with the process.

1.Preparation: Setting Up the Machine

Proper preparation is key to a successful welding process. Here’s how to get started:

- Connect the Power Supply: Start by plugging the machine into a stable power source. Ensure that the voltage matches the required specifications for the machine (usually indicated in the user manual).

- Set Up the Cooling System: Since handheld laser welding machines often generate significant heat, a cooling system is essential. Attach the cooling unit (usually water-cooled) to the machine to keep the components at the right temperature and prevent overheating. Double-check the coolant levels and connections.

- Connect the Laser Fiber Optic Cable: The laser beam is transmitted through the fiber optic cable. Securely attach the fiber to the laser source and the welding head. A properly installed fiber cable ensures the laser will be focused accurately on the material.

- Check the Workpiece: Clean the material you’re about to weld. Remove any dirt, oil, or rust, as these can affect the quality of the weld.

2.Choosing the Right Laser Settings

The settings you choose are crucial for the quality of the weld. Here’s a step-by-step guide to selecting the correct settings:

- قوة الليزر: The laser power determines the depth of the weld. If you’re welding a thick material, you’ll need to increase the power. For thin materials, lower power settings will suffice. Start with the recommended setting in the user manual, then adjust as needed.

- Welding Speed: This refers to how fast you move the welding head. If you go too quickly, the weld might be weak. Moving too slowly can cause overheating. A moderate, consistent speed is usually best. Practice on scrap pieces to find the right speed.

- Focus: Proper focus is essential for precision welding. Adjust the focus lens on the welding head to ensure the laser beam is sharp and concentrated. You can use a test material to check the focus and adjust accordingly.

- Nozzle Size: The nozzle size can affect the welding process. Larger nozzles may be better for thicker materials, while smaller ones are ideal for fine work. Check the nozzle specifications and choose accordingly.

3.Welding Process: Performing the Weld

Once the machine is set up and the settings are chosen, it’s time to weld. Follow these steps to achieve a high-quality weld:

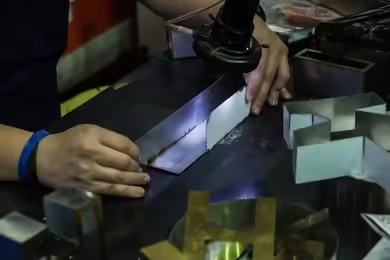

- Position the Welding Head: Hold the welding head about 1 to 2 millimeters above the material’s surface. Keep the nozzle at a consistent angle of around 90 degrees to the workpiece. Ensure the surface is clean and free of contaminants for optimal results.

- Start the Laser Welding: Press the trigger to start the laser. Slowly move the welding head along the joint where you want to create the weld. The laser will begin to melt the material as you move it along the path. Keep a steady hand to ensure an even bead.

- Monitor the Weld: As you move the welding head, observe the weld bead. It should appear consistent and smooth. If the weld is too thin or weak, slow down. If it’s too thick, speed up slightly.

- Avoid Overheating: Laser welding is a fast process, but if you stay in one spot for too long, you risk damaging the material. Ensure that you maintain a consistent pace to prevent overheating or burn-through.

4.Post-Welding Inspection

After completing the weld, allow the material to cool naturally. Inspect the weld for any visible defects such as holes, cracks, or irregularities in the bead. A good weld should be smooth, even, and strong. You can perform a simple strength test by gently tapping the weld or testing its bond with other materials. If necessary, use a grinder to remove any rough edges or excess material.

Key Benefits of Handheld Laser Welding Machines

Handheld Laser Welding Machines offer several unique benefits:

- Precision: The focused laser beam enables precise welding, even on delicate or intricate components.

- Portability: Their compact, lightweight design makes them ideal for on-site or mobile welding.

- سرعة: Laser welding is faster than traditional welding methods, increasing production efficiency.

- Cleanliness: The laser’s precision reduces spatter and the need for post-weld cleaning, saving both time and effort.

- Reduced Distortion: The minimal heat affected zone ensures that surrounding material is not weakened by excessive heat, preserving the integrity of the part.

Common Questions About Handheld Laser Welding Machines

How Do You Maintain a Handheld Laser Welding Machine?

Regular maintenance is key to ensuring long-term performance. Here are some tips:

- Clean the Laser Head: Ensure the laser head and focusing lens are free from dust and debris. Use a microfiber cloth and appropriate cleaning solutions to avoid scratches.

- Check the Cooling System: Ensure the cooling system is functioning efficiently to prevent overheating. Check for leaks and ensure the coolant is replenished as needed.

- Inspect the Fiber Optic Cable: Regularly check the cable for any signs of wear or damage. A damaged cable can affect the laser’s efficiency and accuracy.

Can a Handheld Laser Welding Machine Be Used on All Metals?

Yes, handheld laser welders can work with a wide variety of metals, including stainless steel, aluminum, and titanium. However, each metal may require different settings for optimal results. Always test on scrap material before working on valuable components.

Is It Easy to Learn How to Use a Handheld Laser Welding Machine?

Handheld laser welding machines are generally user-friendly, but mastering them requires dedicated practice. Begin practicing on scrap materials to get a feel for the operation, then experiment with adjusting power and speed settings. Thoroughly reviewing the user manual is also essential to fully understand the machine’s capabilities. With consistent practice, you will steadily improve weld quality and build solid operational confidence.

Looking to explore advanced techniques or industry applications? Visit our expert guide for more professional welding knowledge and practical tips to take your skills to the next level.

The Advantages of Handheld Laser Welding Machines

In conclusion, the Handheld Laser Welding Machine is an invaluable tool for anyone looking to achieve high-quality, precise welds. Its portability, speed, and minimal heat-affected zone make it perfect for both small-scale projects and industrial applications. By following the steps outlined in this guide, beginners can confidently use the machine to produce reliable, clean welds, while also improving their welding skills over time. Whether you’re a professional welder or a hobbyist, investing in a handheld laser welding machine can significantly enhance your welding capabilities.