Unlock Precision: Laser Marking Machine for Metal

Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576014912000

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

In today’s fast-paced manufacturing industry, where quality control and traceability are critical, accurate marking of metal parts is more important than ever.

Traditional marking methods often fall short in terms of durability and clarity, especially in harsh environmental conditions. That’s where laser technology comes in.

In this blog, we’ll show you how metal laser marking can bring new levels of performance to your business. You’ll learn how it works, what the benefits are, common applications, and why now is the best time to consider upgrading your marking processes.

How a Laser Marking Machine for Metal Works

Laser marking machines use concentrated beams of light to alter the surface of metal components, creating marks that are sharp, high-contrast, and resistant to wear. But what happens behind the scenes?

The Core Process Explained

At the heart of every laser marking machine for metal is a laser source—often fiber laser, MOPA laser, or sometimes CO₂ for specific non-metal substrates. When the focused laser beam contacts the surface of the metal, it interacts in one of several ways:

- Annealing: Produces oxide layers without damaging the surface—ideal for medical tools

- Etching: Removes a portion of the material, leaving a noticeable groove

- Engraving: Cuts deeper into the metal for long-term durability

- Color Marking: Uses controlled oxidation to produce different hues (commonly used on stainless steel)

Each marking type has its own use case, and the choice depends on your application needs, material type, and performance expectations.

Comparison of Laser Marking Technologies for Metal

To help you choose the right system, here’s a comparison of common laser types used for metal marking:

| Laser Type | Suitable Metals | Typical Marking Method | Lifespan (Hours) | Advantages | Applications |

|---|---|---|---|---|---|

| Fiber Laser | Stainless steel, Aluminum, Brass, Titanium | Etching, Engraving, Annealing | Up to 100,000 | Fast, low-maintenance, high precision | Automotive parts, electronics, tools |

| MOPA Laser | Stainless steel, Colored marking | Color marking, Deep engraving | ~80,000 | Flexible pulse control, color capabilities | Medical tools, consumer goods branding |

| CO₂ Laser | Coated metals, Plastics (not raw metal) | Surface marking | ~30,000 | Cost-effective for specific non-metal tasks | Packaging, coated nameplates |

Choosing the correct type of laser depends not only on the material but also on the visual effect, marking depth, and production speed you require.

Benefits of Using a Laser Marking Machine for Metal

Wondering what sets laser marking apart from traditional solutions? Here’s why manufacturers worldwide are making the switch.

Unrivaled Accuracy and Consistency

Laser marking offers micron-level precision, crucial for industries where even the smallest misalignment can lead to quality control failures. Thanks to computerized controls and vision systems, every part is marked identically—even during high-speed batch production.

Low Operating Costs and Maintenance

Although the initial investment might seem significant, fiber lasers typically have lifespans of up to 100,000 hours and require minimal maintenance. There’s no ink, no chemicals, and virtually no consumables involved.

Environmentally Friendly

Compared to chemical etching or ink-based printing, laser marking is a clean technology. It reduces waste, emissions, and health hazards, aligning with sustainable production practices.

Adaptability Across Metals and Shapes

From flat aluminum nameplates to cylindrical stainless-steel tools, laser marking machines adapt seamlessly. With adjustable focal lengths and rotary attachments, even complex geometries aren’t a challenge.

Common Applications of Laser Marking on Metal

Different industries have different expectations, and laser technology meets them with ease. Here’s a look at where and how laser marking shines.

1. Automotive Parts Identification

VIN codes, gear numbers, and safety compliance marks are frequently laser-etched into car parts to withstand heat, friction, and chemicals.

2. Medical Device Marking

According to the FDA Unique Device Identification (UDI), all medical devices must have readable, durable markings. Laser annealing ensures no corrosion or material fatigue—critical for surgical tools and implants.

3. Aerospace Component Tracking

Laser marking provides permanent traceability on critical components, allowing for lifecycle monitoring and quick recall in case of failure.

4. Industrial Machinery and Tooling

Asset tagging, part numbering, and brand engraving—laser marking ensures every tool in your facility is identifiable and traceable.

5. Electronics and Consumer Goods

Serial numbers, logos, and data matrix codes on metal casings or circuit boards are best applied with laser for speed and precision.

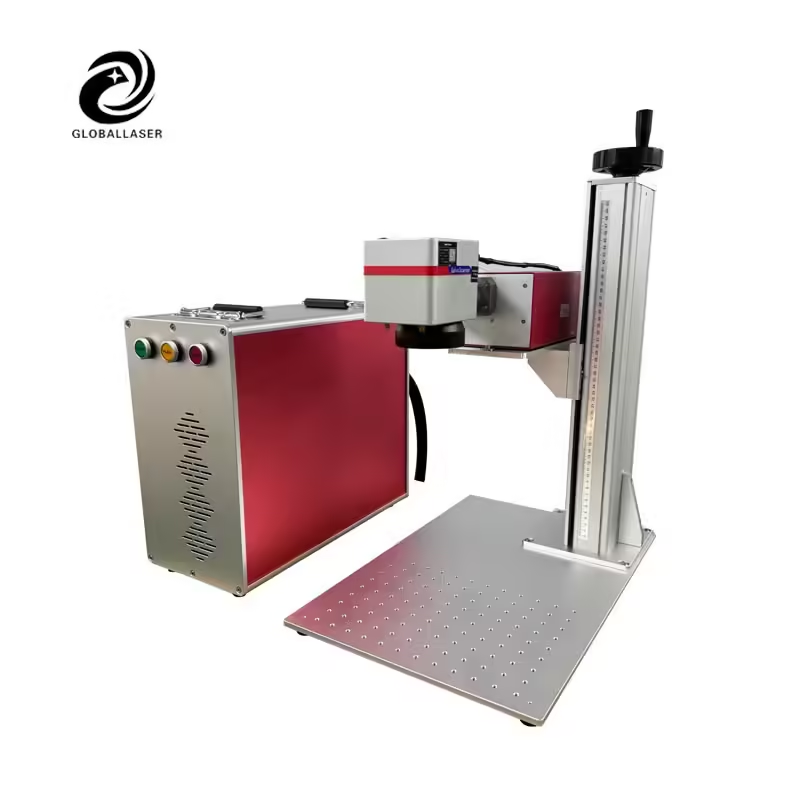

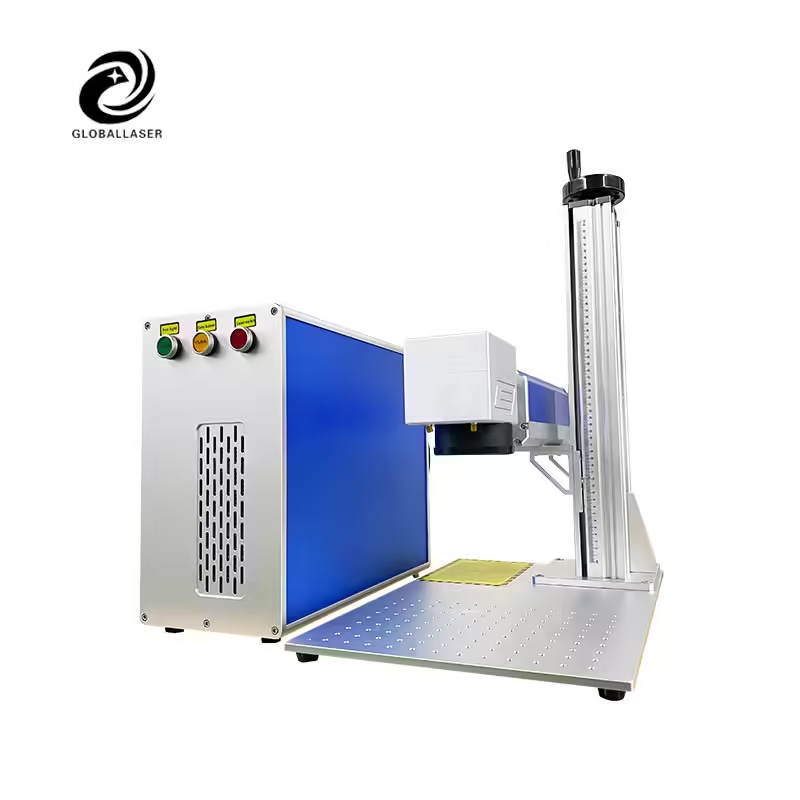

Choosing the Right Laser Marking Machine for Metal

What Should You Consider?

Before making a purchase, think about the following:

- Type of Metal: Fiber lasers are ideal for most metals, but softer materials might benefit from a MOPA configuration

- Marking Speed: Batch production environments require faster marking systems

- Precision Requirements: For micro-marking applications (e.g., electronics or medical tools), high-resolution systems are a must

- Automation Capability: Integration with conveyor lines or robotic arms can boost productivity

If you’re not sure which model suits your workflow, don’t worry—our team is here to help you make the right decision based on your production needs.

Future Trends: Smart Marking and Digital Traceability

The evolution of smart manufacturing is bringing even more demand for precise, digital identification. Laser marking machines for metal are now being integrated into Industry 4.0 ecosystems, enabling real-time data logging, cloud-based traceability, and even blockchain tracking for supply chains.

According to a 2024 report by MarketsandMarkets, the global laser marking market is projected to grow from USD 3.5 billion in 2023 to USD 5.2 billion by 2028, driven by increasing automation and regulatory compliance across sectors.

Conclusion

Precision, permanence, and productivity—these aren’t just buzzwords. They’re what your business gains when you invest in a laser marking machine for metal. Whether you’re scaling up your production or looking to improve traceability and compliance, laser marking is the solution you’ve been searching for.

Don’t let outdated marking systems hold you back. SDGlobal Laser combines cutting-edge technology with real-world application expertise to help you find the ideal solution tailored to your industry needs.

FAQ

Will laser marking damage my metal part?

Not necessarily. Most laser marking types, especially annealing, do not compromise the structural integrity of the part.

Can laser marking be removed?

Not easily. Laser marks are designed to be permanent. They’re resistant to abrasion, heat, and chemicals.

Is laser marking safe?

Yes. With proper machine guarding and safety interlocks, it’s a safe, enclosed process.

How long does it take to mark a single part?

Marking time varies by content and size but typically ranges from 0.5 to 5 seconds per part.

What industries benefit the most?

Industries such as automotive, aerospace, electronics, and medical manufacturing see the most benefit due to their need for durability and compliance.