Choosing the Best Laser Marking Machine for Metal

Table of Contents

Introduction

Metal marking is one of the most demanding and essential processes in modern manufacturing. From automotive components to medical instruments, every industry requires durable, legible, and permanent markings for identification, branding, and traceability. Choosing the right laser marking machine for metal can dramatically improve production efficiency, reduce maintenance costs, and ensure compliance with international quality standards.

Today, laser marking is replacing traditional engraving and chemical etching due to its precision, non-contact process, and environmental friendliness. But with so many technologies available—fiber, CO2, and UV—how can manufacturers decide which laser marking machine for metal offers the best results? This article explores the key principles, technologies, and application-specific recommendations to help you make an informed decision.

Understanding Laser Marking for Metal

Laser marking is a process that uses concentrated light energy to create marks on the surface of a material. When applied to metal, the laser interacts with the material’s surface to alter its structure or color, producing permanent markings that can withstand corrosion, heat, and wear.

There are four main types of marking results on metal surfaces: engraving, annealing, ablation, and etching. Each result depends on the laser type, power, and pulse duration.

Types of Metal Laser Marking Effects

| Marking Type | Description | Ideal Laser Source |

|---|---|---|

| Engraving | Removes material to create deep, tactile marks | Fiber Laser |

| Annealing | Creates oxidation-based color changes without surface damage | Fiber or UV Laser |

| Ablation | Removes coatings, paint, or oxide layers | Fiber or CO2 Laser |

| Etching | Creates shallow patterns with smooth edges | Fiber Laser |

Among all, fiber laser marking is the most commonly used for metals because of its wavelength efficiency, low maintenance, and high contrast performance.

Why Choose Laser Marking for Metal Over Traditional Methods

Laser marking offers several key advantages compared to mechanical engraving or ink printing.

- Permanence – The marks are corrosion-resistant, heat-resistant, and abrasion-proof.

- High Precision – Laser beams can achieve micron-level accuracy with no tool wear.

- Speed – Non-contact marking ensures high-speed operation suitable for mass production.

- Eco-Friendly – No chemicals, solvents, or consumables are required.

- Automation-Ready – Laser systems integrate seamlessly into production lines and robotic systems.

These advantages make laser marking the standard choice for industries seeking clean, durable, and traceable identification on metal surfaces.

Types of Laser Marking Machines for Metal

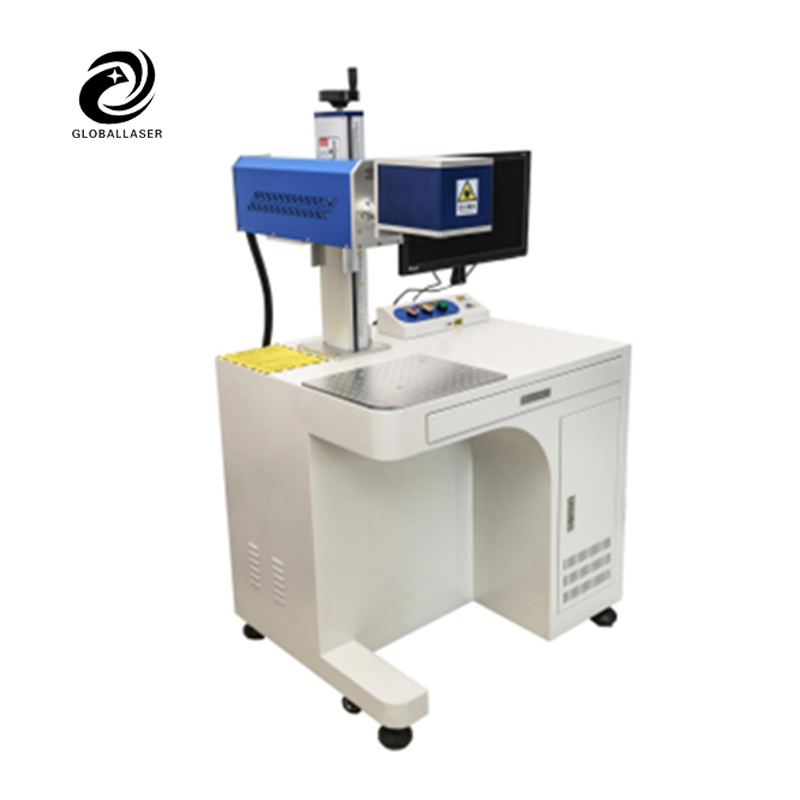

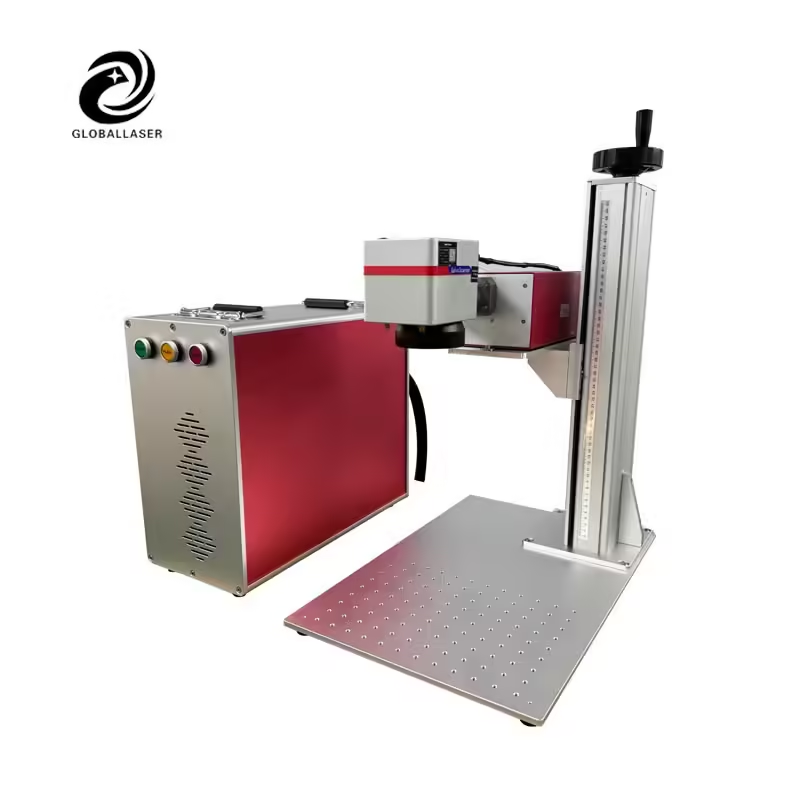

1. Fiber Laser Marking Machine

The fiber laser marking machine for metal is the most efficient and widely used technology today. It emits a wavelength of 1064 nm, which is highly absorbed by metals such as stainless steel, aluminum, copper, and brass. Fiber lasers offer high beam quality, low operating costs, and virtually maintenance-free performance.

Best for:

- Stainless steel, carbon steel, aluminum, titanium, brass

- Deep engraving, serial number marking, logo etching

- Industrial and automotive components

2. CO2 Laser Marking Machine

Although CO2 lasers are primarily used for non-metal materials, they can mark coated metals or anodized aluminum effectively. CO2 lasers operate at a 10.6 μm wavelength, making them ideal for removing surface coatings or paints.

Best for:

- Coated metals, anodized aluminum, painted surfaces

- Applications requiring surface contrast without deep penetration

3. UV Laser Marking Machine

UV laser marking machines for metal operate at a wavelength of 355 nm and are known for their “cold processing” effect. This means the laser causes minimal heat damage, making it perfect for marking delicate or heat-sensitive metals such as gold, silver, and copper.

Best for:

- Micro-electronics, jewelry, medical devices

- Fine detail marking and high-contrast identification

4. MOPA Fiber Laser Marking Machine

MOPA (Master Oscillator Power Amplifier) lasers offer flexible pulse width control, allowing for color marking on stainless steel and titanium. They also provide smoother marking on thin metal sheets.

Best for:

- Color engraving, precision branding, decorative metal marking

- High-end consumer electronics and luxury products

Comparative Table: Choosing the Right Machine

| Feature | Fiber Laser | CO2 Laser | UV Laser | MOPA Fiber |

|---|---|---|---|---|

| Wavelength | 1064 nm | 10.6 μm | 355 nm | 1064 nm (variable pulse) |

| Metal Compatibility | Excellent | Limited (coated metals) | Excellent for fine detail | Excellent, with color control |

| Engraving Depth | Deep | Surface only | Shallow | Deep or decorative |

| Maintenance | Very Low | Moderate | Low | Low |

| Cost Efficiency | High | Moderate | High | Moderate |

| Ideal Use | General metal marking | Coated surfaces | Precision micro-marking | Color marking |

From the comparison above, fiber laser marking remains the most versatile and cost-effective solution for general metal marking applications. UV and MOPA systems are better suited for specialized industries requiring aesthetic or ultra-precise marking.

Key Factors to Consider Before Choosing

1. Type of Metal

Different metals respond uniquely to laser wavelengths. For instance, aluminum and stainless steel require higher energy density, while softer metals like gold and copper demand lower pulse energy to avoid distortion.

2. Marking Depth and Contrast

For industrial traceability, deep and high-contrast marks are essential. Fiber lasers excel in this area, while UV lasers offer better contrast for small characters or QR codes.

3. Production Volume and Speed

High-speed fiber lasers are suitable for large-scale production. Handheld or desktop versions can be selected based on workspace and part size.

4. Budget and Maintenance

While fiber laser systems may have higher upfront costs, their maintenance-free operation and long lifespan make them more economical in the long term compared to CO2 or ink-based methods.

5. Automation Integration

Modern fiber laser marking machines can be integrated with conveyor belts, robotic arms, or vision inspection systems for automated marking. This is ideal for industries aiming for smart factory setups.

Applications of Laser Marking Machines for Metal

Automotive Industry

Laser marking is used for part identification, VIN codes, and branding on engine components, brake systems, and metal housings. The marks are resistant to oil, heat, and mechanical wear.

Aerospace and Defense

The laser marking machine for metal ensures precise traceability on high-value components such as turbine blades, fuel nozzles, and structural frames, complying with strict aerospace quality standards.

Medical Devices

For surgical instruments and implants, UV and MOPA lasers offer precise, corrosion-resistant marking that meets FDA and ISO 13485 traceability regulations.

Electronics Manufacturing

Marking PCBs, aluminum casings, and metal connectors with fiber or UV lasers ensures permanent identification without damaging sensitive electronic circuits.

Maintenance and Safety Considerations

To ensure consistent marking quality, operators should regularly clean the lens, verify focus calibration, and maintain a dust-free environment. Always wear proper laser safety goggles and follow Class 4 laser safety standards.

Software updates and proper cooling are essential for maintaining beam stability. Many modern systems include built-in safety interlocks and temperature sensors for added reliability.

Conclusion

Selecting the best laser marking machine for metal depends on your specific materials, production requirements, and quality goals. Fiber lasers deliver the highest overall performance, offering deep, durable, and fast marking for most industrial applications.

For micro-engraving or aesthetic designs, UV and MOPA lasers provide advanced control and stunning results. Whether your priority is precision, speed, or visual appeal, understanding the capabilities of each laser type ensures your investment delivers long-term productivity and brand value.

The right laser marking solution will not only enhance your manufacturing quality but also elevate your brand’s technological edge in an increasingly competitive global market.

FAQ

Which laser type is best for marking stainless steel?

A fiber laser or MOPA fiber laser offers the best results for stainless steel, providing deep, high-contrast markings and even color engraving options.

Can a CO2 laser mark bare metal?

Not effectively. CO2 lasers are best for coated or anodized metals since their wavelength is not well absorbed by raw metallic surfaces.

What is the average lifespan of a fiber laser marking machine for metal?

Typically 100,000 working hours or more, with almost no maintenance required apart from lens cleaning.

How deep can a fiber laser engrave on metal?

Depending on the power (20W–100W), it can engrave from 0.1 mm up to 1.5 mm deep with multiple passes.

Is laser marking safe for food-grade metals?

Yes, fiber and UV lasers produce clean, non-toxic marks suitable for stainless steel utensils, containers, and medical-grade tools.