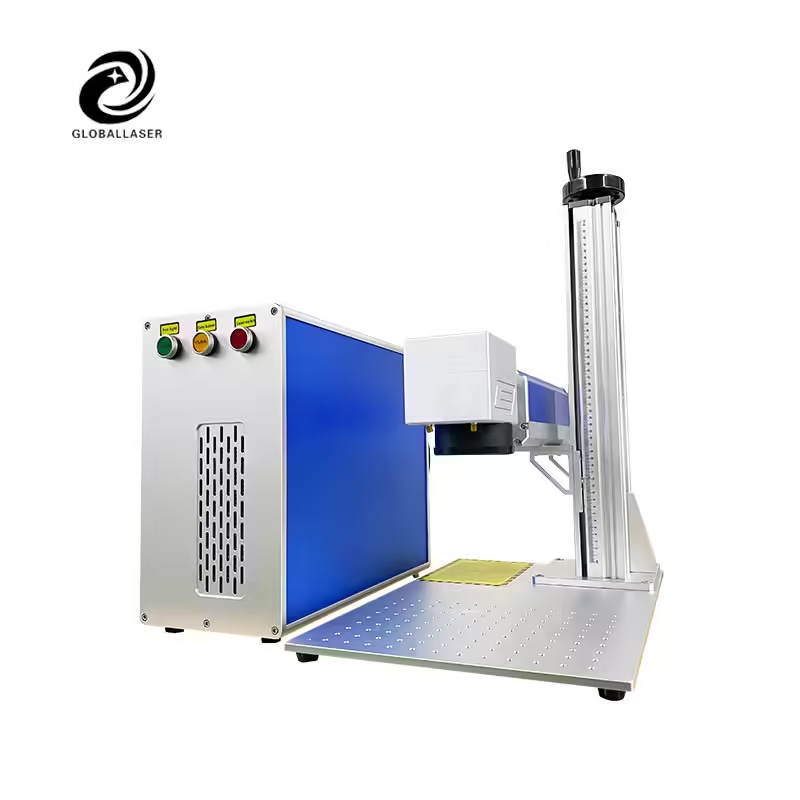

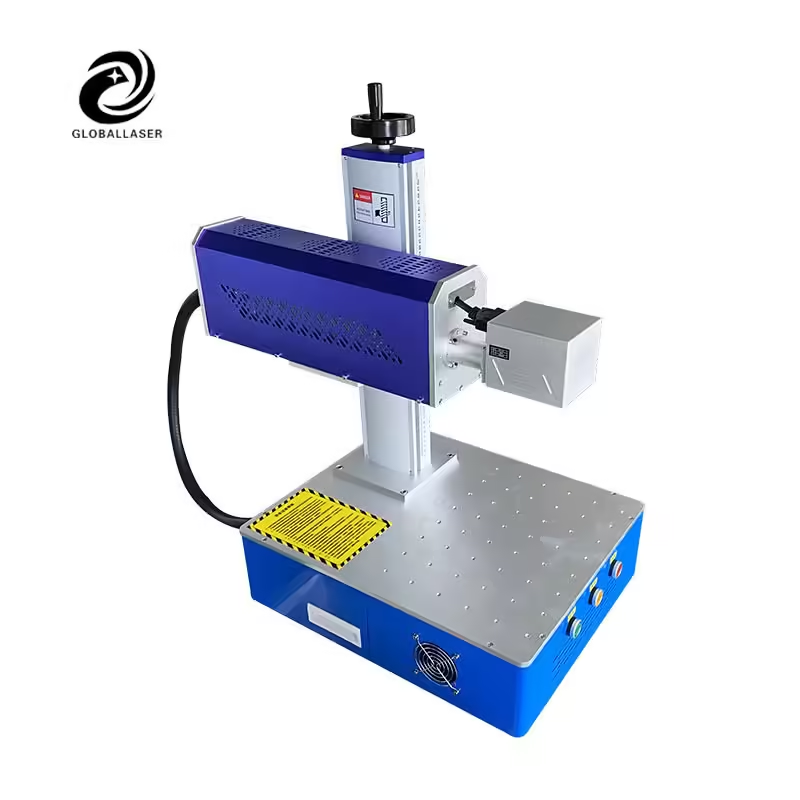

The cabinet - type ultraviolet laser marking machine

The cabinet - type ultraviolet laser marking machine

UV marking machines are mainly used in the high-end market of ultra-fine processing, including pharmaceuticals, cosmetics, videos, and other polymers The surface of the packaging bottle of the material is marked with a very fine effect, and the marks are cleaned firmly, which is better than ink coding and pollution-free; flexibility PCB board marking and cutting; Silicon wafer micro hole and blind hole processing; LCD LCD glass QR code marking, glassware surface Punching, metal surface coating marking, plastic buttons, electronic components, gifts, and more.

What is UV Laser Marking Machine?

The UV Laser Marking Machine is a high-precision laser processing machine known for its high precision, cold processing and fine marking capabilities. With its 355nm UV laser, the UV Laser Marking Machine specializes in fine engraving, marking or etching on a wide range of materials, especially for heat sensitive materials.

Due to its high-precision cold processing characteristics, UV laser marking machines are able to achieve extremely high marking accuracy, marking fine patterns as small as 0.01 mm, and generating almost no heat, avoiding thermal damage to the material. This characteristic makes it excellent in electronic components, medical devices, jewelry and other industries, and can clearly and accurately mark tiny text, complex patterns and high-precision 2D codes.

Product Parameters

| Laser Power | 3W/5W/10W |

| Size | 880*550*1370mm |

| Net Weight | 65kg |

| Marking Area | 100×100/150×150/200×200mm |

| Minimum Line Width | 0.01mm |

| Marking Speed | 0-5000mm/s |

| Cooling System | Water-cooled |

| Positioning Method | Red Light Preview |

Applications of UV Laser Marking Machine

-

Electronics Industry: Marks microchips, circuit boards, and other small electronic components with high precision and minimal heat damage。

-

Medical Device Manufacturing: Creates permanent, high-contrast marks on medical devices such as syringes, catheters, and surgical instruments without compromising material integrity。

-

Plastics and Polymers: Marks various plastic materials like polyamide, PVC, and ABS with high absorption rates, ensuring clear and durable marks。

-

Glass and Ceramics: Marks glass and ceramic products with high precision and minimal risk of cracking or damage。

-

Automotive Industry: Marks in-vehicle plastic parts and other components with high contrast and durability。

-

Cosmetics and Packaging: Marks packaging materials like glass or plastic bottles with intricate logos or serial numbers without affecting appearance or structural integrity。