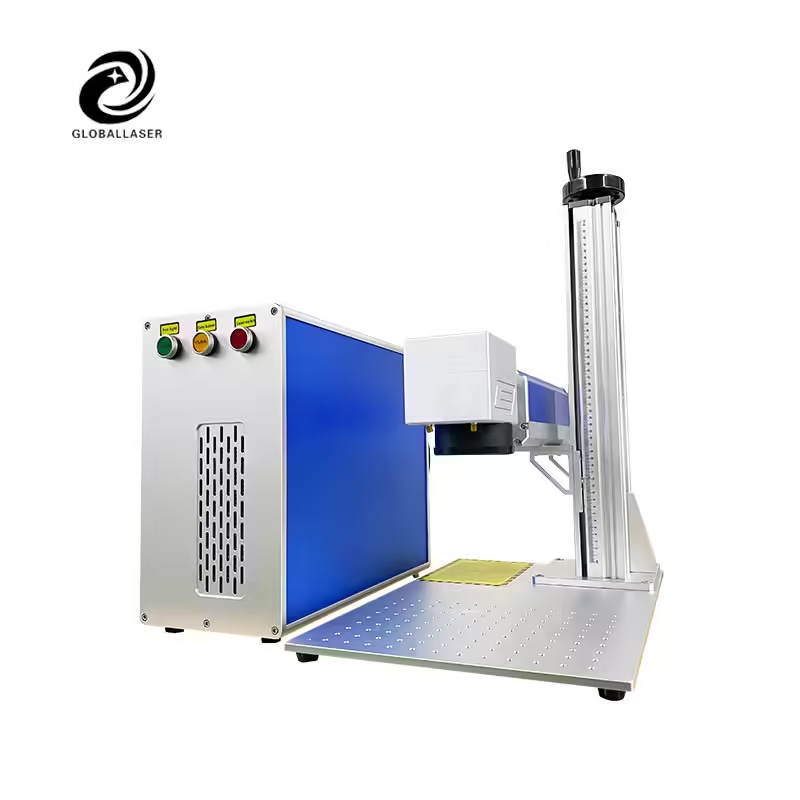

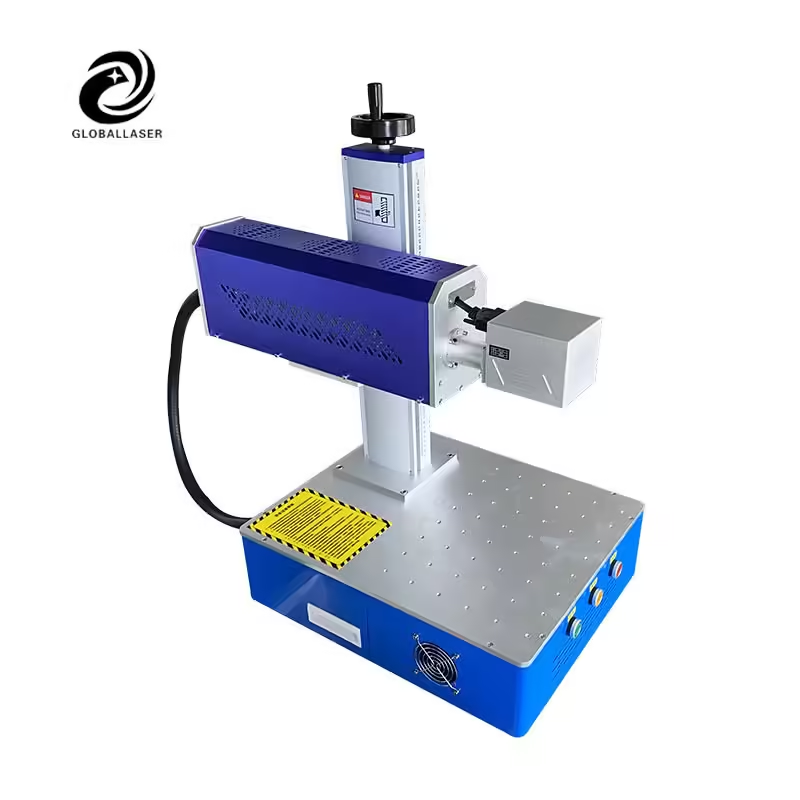

JG-1000RSRW-A

JG-1000RSRW-A

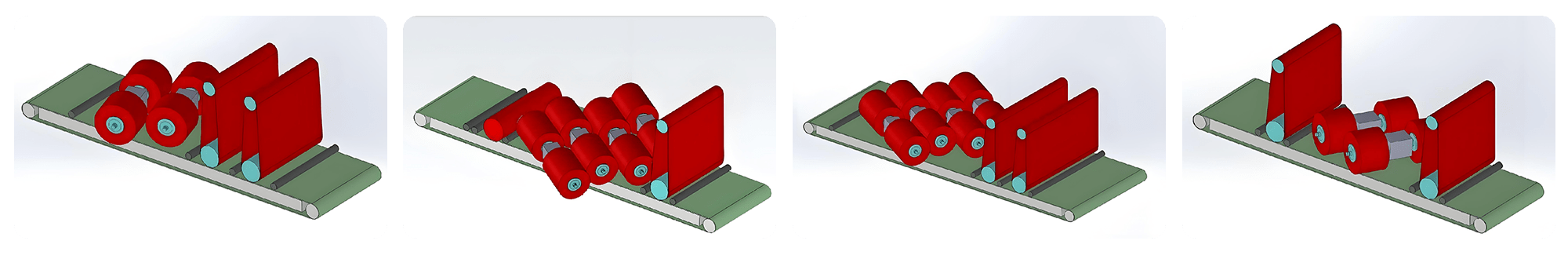

METAL DEBURRING, CHAMFERING AND DRAWING MACHINE The Equipment is Upgraded on the Conventional Basis, with Thickened and Eccentric Sand Rack Rollers and Overall Dynamic Balance. The Machine is Heavier And Thicker, With Lower Noise and Higher Stability. It Can Realize One-Pass Processing of Workpieces and is Suitable for Surface Pre-Grinding of Metal Plates, Deburring of Holes and Edges, As Well As Surface Wire Drawing and Descaling.

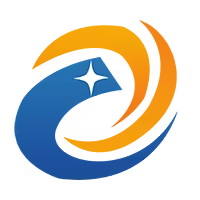

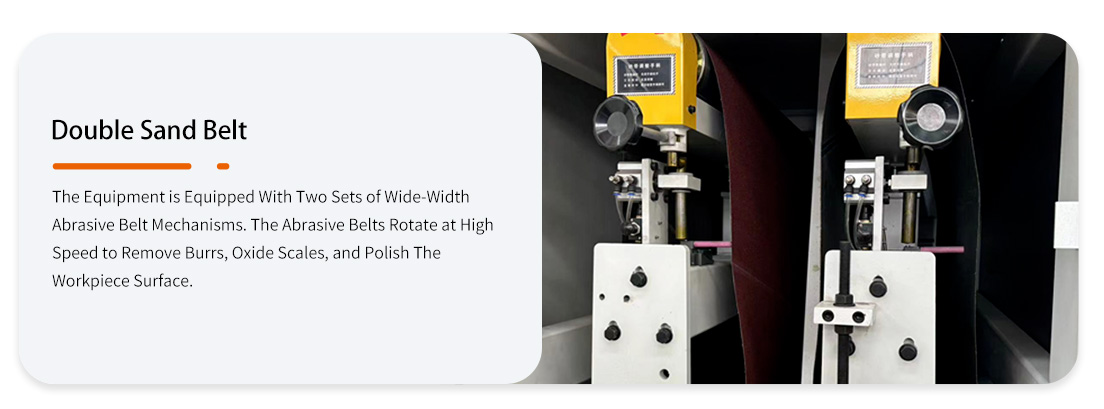

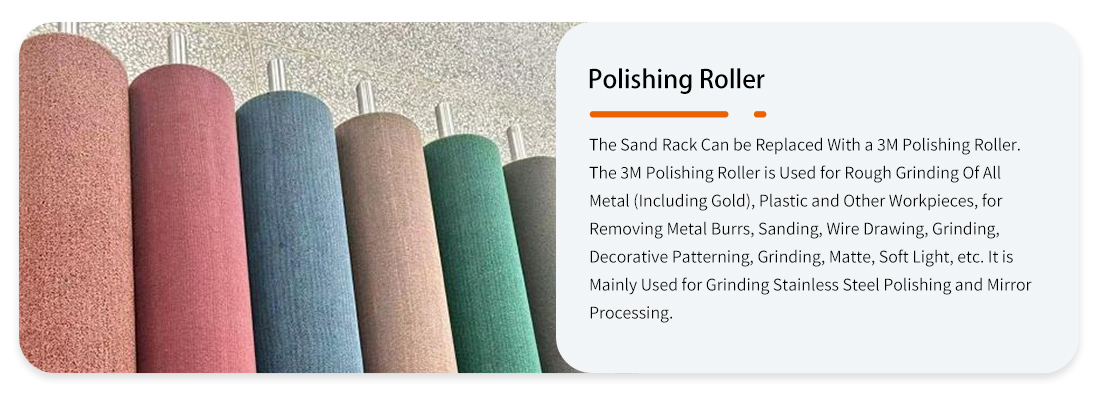

Optional Structure

Parameter Configuration

| Name | JG-1000RSRW-A |

| Maximum machining width | 1000mm |

| Fixed transpotation method | Vacuum adsorption |

| Processing thickness | 0.8-80mm |

| Sand belt size | 1020*2200mm |

| Minimum processing size | 60*60mm |

| Roller brush diameter | 300mm*300mm*40mm |

| Number ofroller brushes | 6 |

| Power up and down | 1.5KW |

| Feeding speed (frequency conversion) | 1-5m/min |

| Rubber roller diameter (eccentric) | 195mm |

| Total power | 35kw |

| Working pressure | ≥0.55Mpa |

| External dimensions | 4000*1800*2300mm |

| Weight | 4400kg |

| Default voltage | Three-phase 380v |

| Electrical components | Chint/Delixi |

| Grinding shell | Standard double sanding belts,customizable multiple sanding bells |

Pre-Sales Service

Free Sample Cutting Service

For free sample cutting/testing, please send us your CAD file (.plt or .ai), we will cut it in our factory and make a video to show you the cutting process and results, or send you a sample to check the cutting quality.

Advancing Solution Design

According to the customer’s product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

Custom Machine Design

Depending on the customer’s application, we can modify our machines to achieve customer’s convenience and high production efficiency.

After-Sales Service

- We will provide training videos and English user manuals for installation, operation, maintenance and troubleshooting for the laser machine, and will provide technical guidance via remote means, such as TeamViewer, email, phone, mobile, Whatsapp, Skype, 24/7 online chat, etc., when you encounter installation, operation or adjustment problems. (Recommended)

- You can come to our laser machine factory for training. We will provide professional guidance. Direct and effective face-to-face training. We have assembled machines, various tools and testing facilities here. Training time: 3 to 5 days (recommended)

- Our engineers will provide on-site guidance and training services in your local area. We need your assistance in visa procedures, prepayment of travel expenses, and accommodation before the dispatch and during the service. During the training, it is best to arrange a translator for our engineers (if they do not speak English).

Warranty Policy

- 3 years for the whole machine, 18 months for the laser, 12 months for the chiller, no warranty for the lens/mirror/nozzle.

- Long-term lifetime maintenance, the after-sales department will provide 24/7 English online support.

- Except for man-made damage, we are responsible for providing accessories free of charge during the warranty period.

- After the warranty period, the buyer only needs to pay for the actual repair costs.

- Certificate support: CE, FDA, SGS.

Small Package

- Strong waterproof bottom made of plywood.

- Spare parts for the laser source (separate plywood housing) and laser bed.

- Corners are protected with foam and secured with protective film.

- All covered with a strong, hard protective film.

- Vacuum packed.

- Internal steel frame protectors.

- Plywood packaging and steel strapping outside to secure the box.

- Packing is done using regular containers or flat rack containers.

Customer Testimonials

High recognition from global customers testifies to SDGlobal Laser's excellent quality and service

Faq

We answer some common questions for you to help you better understand our products and services.

What Types of Laser Cutting Machines Are There?

What Are the Maintenance Precautions for Laser Cutting Machines?

Factors that affect the processing performance of laser marking machines?

How do I choose the right laser machine for my business?

Do you provide after-sales service?

Is the equipment installation complicated?

Related Products

Global Service, Responsive At Any Time

If you have any questions, please feel free to contact us and we will answer you as soon as possible. Whether it is products, services or after-sales, just contact us and we will provide you with a satisfactory and thoughtful service experience.