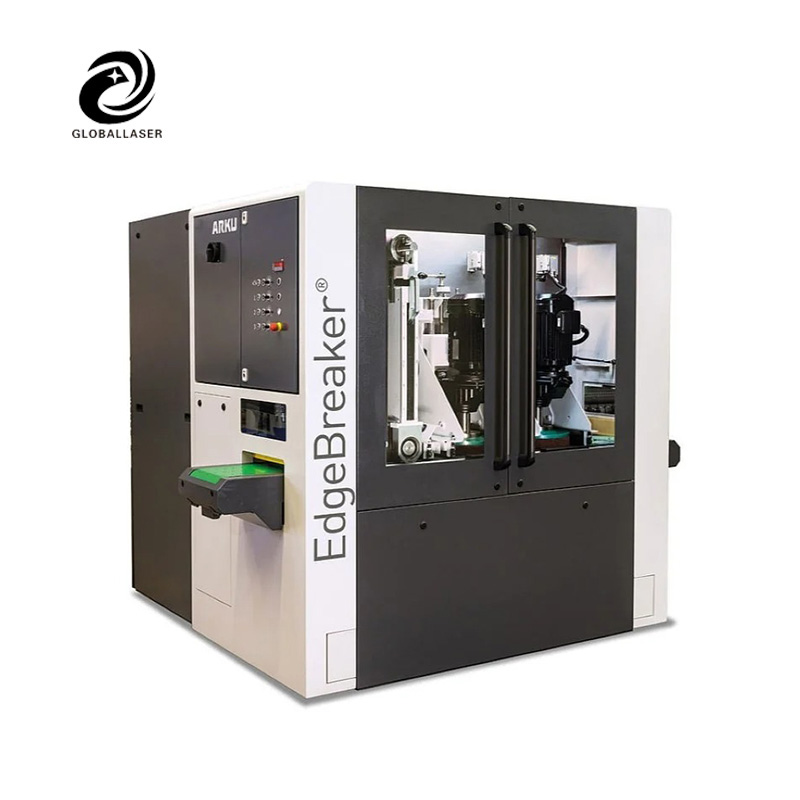

EdgeBreaker® 1000

EdgeBreaker® 1000

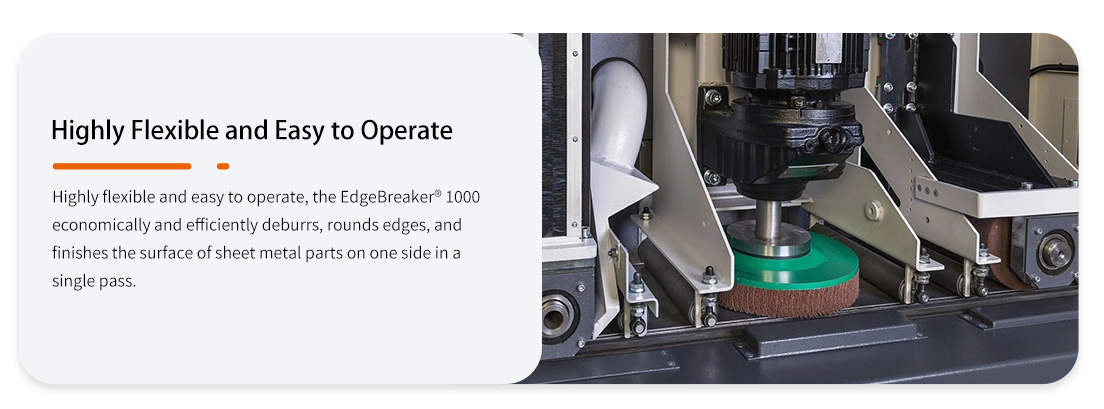

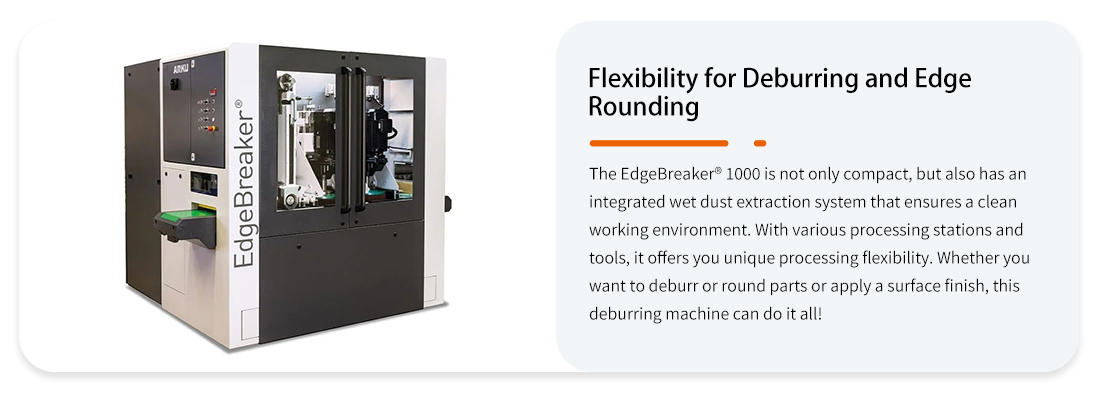

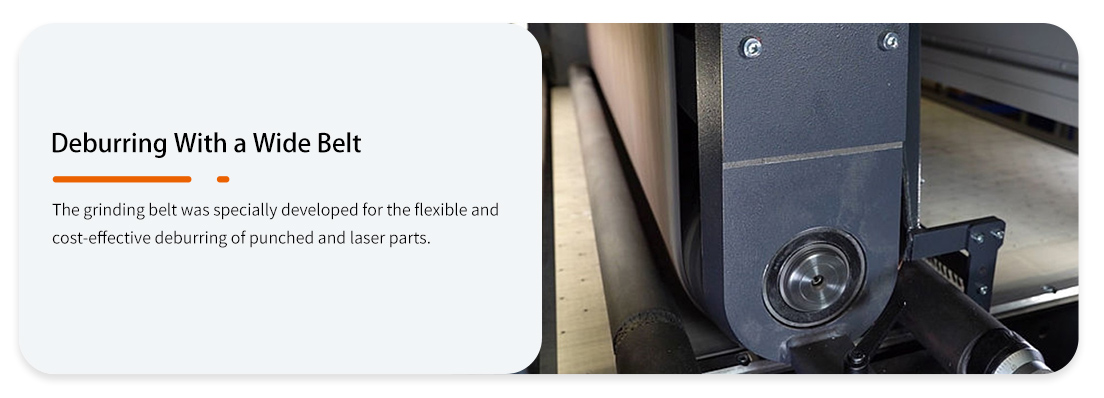

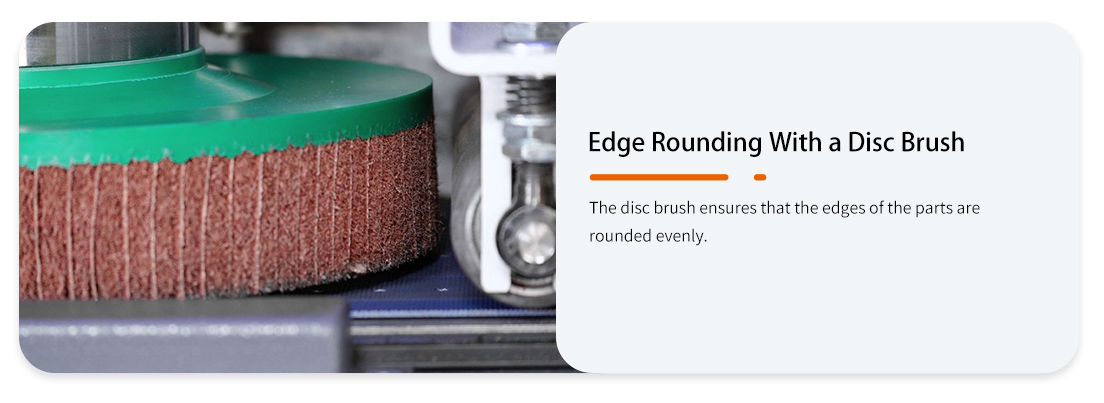

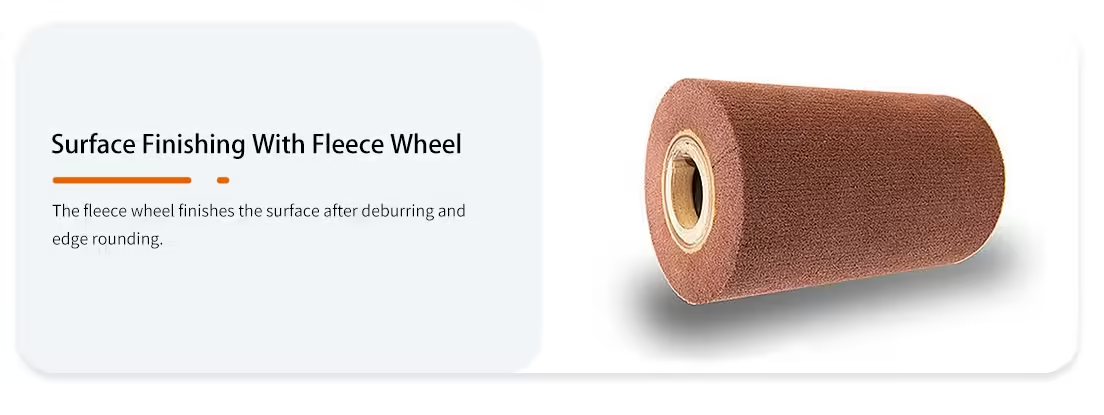

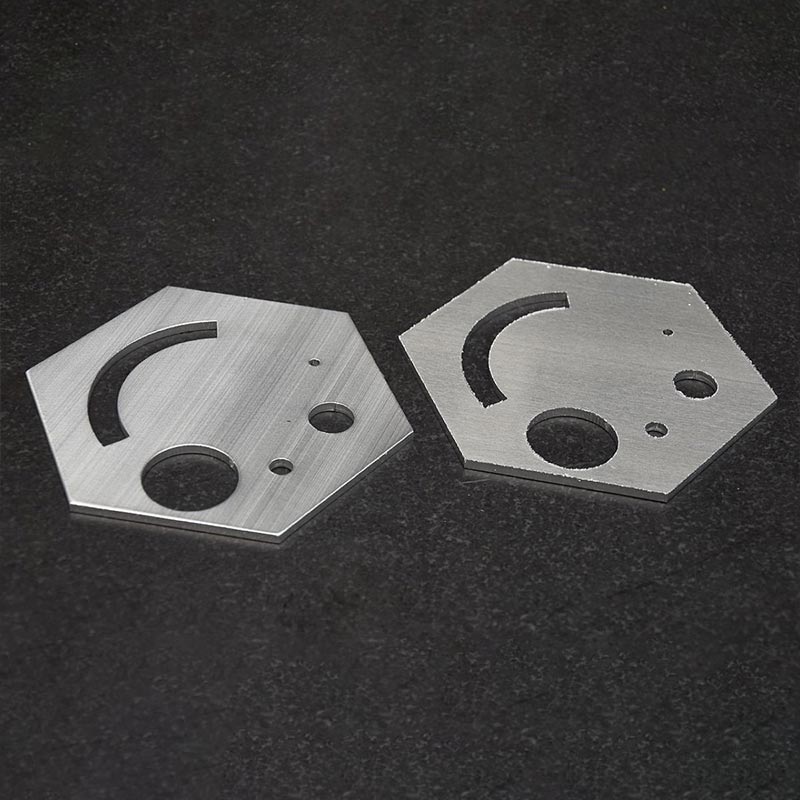

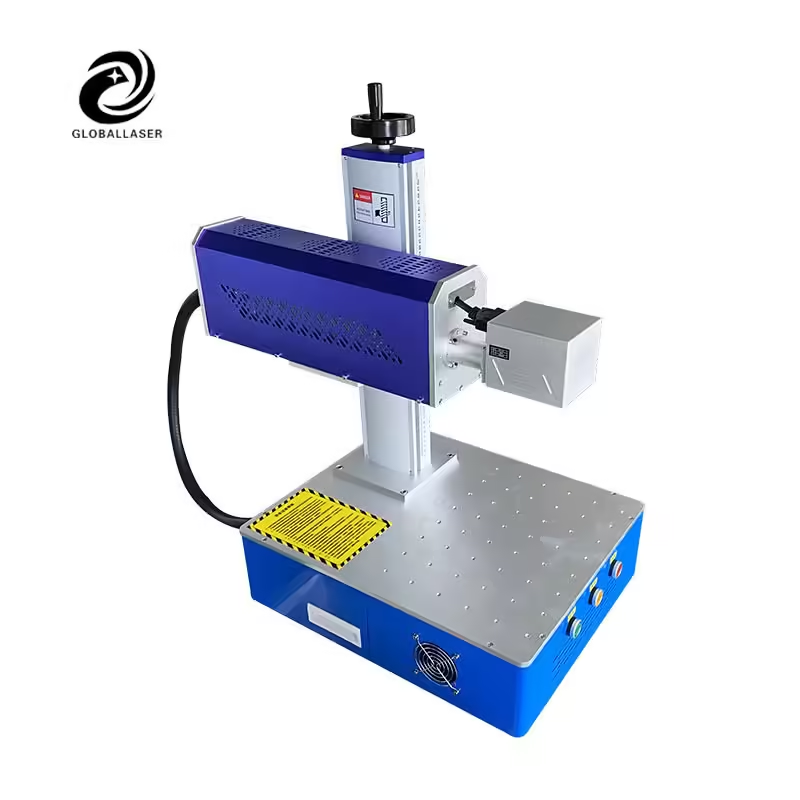

Cost-effectively deburr, edge round and surface finish small sheet metal parts after laser cutting and punching thanks to the single-sided EdgeBreaker® 1000 deburring machine. This machine is a plug and play concept since it has a wet dust extraction system already built in, allowing you to process all metal alloys safely. The result is a well-thought-out machine concept which is easy to use, with high flexibility and outstanding performance. Single-sided deburring, edge rounding, and surface finishing of small parts cut from sheet metals are crucial processes in various industries like automotive, aerospace, electronics, and manufacturing.

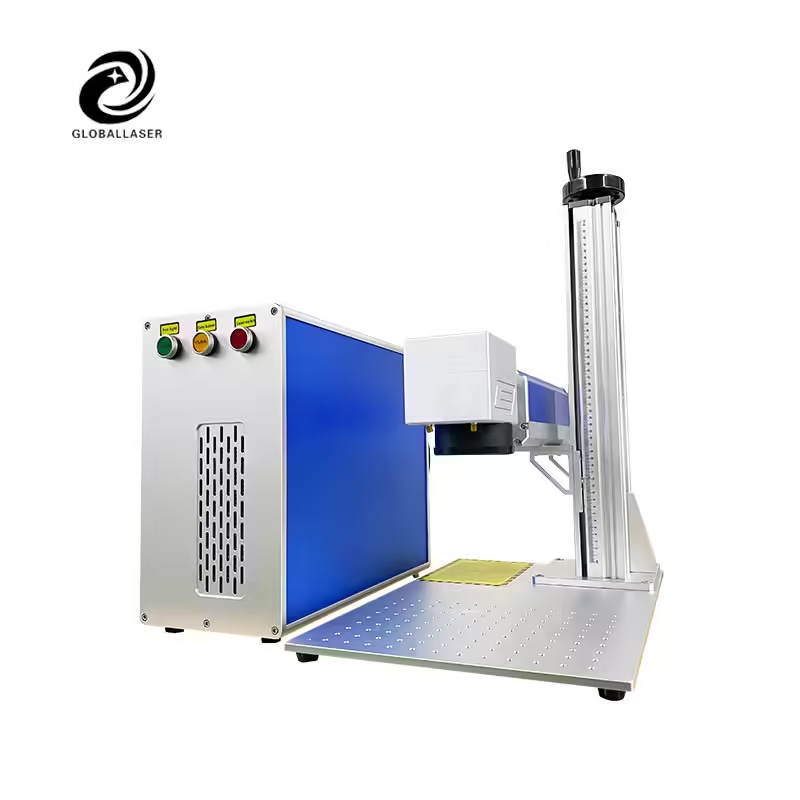

Deburring with the smallest space requirement

Thanks to the compact design of the EdgeBreaker® 1000 and the integrated wet dust extraction system, you save valuable manufacturing floor space. The machine can easily be integrated into existing production lines while still offering outstanding performance. Regardless of whether you want to deburr small sheet metal parts, round them, or apply a surface finish, the EdgeBreaker® 1000 is the ideal machine.

Integrated dust extraction

A wet dust extraction system is already integrated in the deburring machine. Thanks for it being wet, mixed materials such as steel and aluminum can be processed safely. This setup also saves a ton of valuable manufacturing space. It also makes it very easy to set up or move the machine.

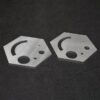

Quick-change for edge rounding and deburring tools

All processing units (deburring and edge rounding) are equipped with a quick-change system for the tools (abrasives) to minimize set=up times. You can simply remove the brushes and click them back in, without any tools needed! The machine can be outfitted with a variety of different tools (various grits and material composites are available). All for optimum deburring and edge rounding results to suit your changing requirements.

| Processing | single-sided, dry |

| Material thickness | 0.02″ – 1″ (0.5 – 25 mm) |

| Max. passageway width | 9.8″ (250 mm) |

| Weight | approx. 7,700 lbs (3,500 kg) |

| Dimensions (L x W x H) | approx. 83″ x 102″ x 83″ (2,100 x 2,600 x 2,100 mm) |