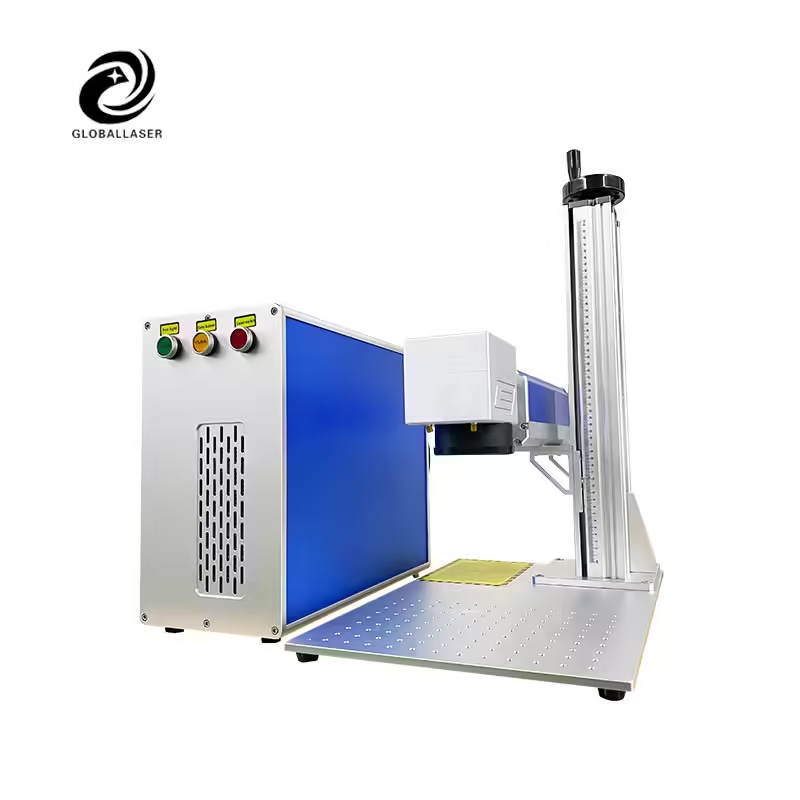

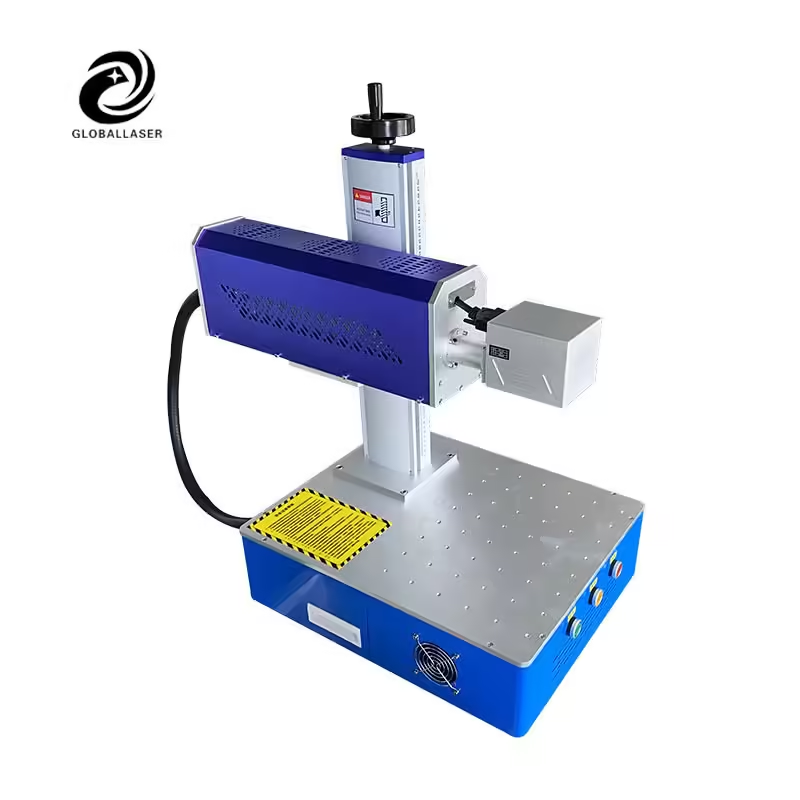

3D Dynamic Focusing Marking Machine

3D Dynamic Focusing Marking Machine

The 3D series galvanometer uses customized core components, equipped with high-speed, high-precision galvanometers, combined with 3D-specific software and control systems,perfectly realizes the fine processing of any curved surface workpiece without out-of-focus phenomenon; it can also track the deep engraving focus in real time,making the processing efficiency and quality better than traditional 2D marking machines. Truly fully realize 3D marking function

What Is a 3D Dynamic Focusing Marking Machine?

The 3D Dynamic Focusing Marking Machine is an advanced laser processing machine, highly acclaimed for its high precision, flexibility and superior surface processing capabilities. With its unique 3D dynamic focusing technology, the machine is specialized in fine engraving, marking or etching on complex curved surfaces, spheres and irregular surfaces. Its high-precision 3D galvanometer system adjusts the laser focus in real time to ensure uniformity and depth control on surfaces of varying curvature, resulting in high-quality machining results.

Product Parameters

| Laser Wavelength | 1064nm |

| Laser Power | 20/30/50/60/100w(Optional) |

| Marking Speed | ≤7000 mm/s |

| Marking Range | 70*70mm、110*110mm、150*150mm、175*175mm、200*200mm(Optional) |

| Positioning Method | Red light preview |

| Cooling Method | Air Cooling |

| Power Supply | 110v/220v(Optional) |

Applications of 3D Dynamic Focusing Marking Machine

-

Automotive and Aerospace Industries: Marks complex components like engine parts, gears, and aircraft parts with high precision on curved and irregular surfaces。

-

Medical Device Manufacturing: Engraves detailed information and logos on medical instruments and implants, ensuring high-quality and durable marks。

-

Electronics Industry: Marks electronic components, circuit boards, and other small parts with high precision and speed。

-

Jewelry Industry: Engraves intricate designs, logos, and personalized messages on jewelry items, including rings and bracelets。

-

General Manufacturing: Marks a variety of products with different shapes and sizes, including cylindrical, spherical, and curved surfaces。

-

Promotional and Custom Products: Creates personalized and promotional items with high-quality engravings, such as engraved cups and custom gifts。

Product Details

Customer Testimonials

High recognition from global customers testifies to SDGlobal Laser's excellent quality and service

Faq

We answer some common questions for you to help you better understand our products and services.

What Types of Laser Cutting Machines Are There?

What Are the Maintenance Precautions for Laser Cutting Machines?

Factors that affect the processing performance of laser marking machines?

How do I choose the right laser machine for my business?

Do you provide after-sales service?

Is the equipment installation complicated?

Related Products

Global Service, Responsive At Any Time

If you have any questions, please feel free to contact us and we will answer you as soon as possible. Whether it is products, services or after-sales, just contact us and we will provide you with a satisfactory and thoughtful service experience.