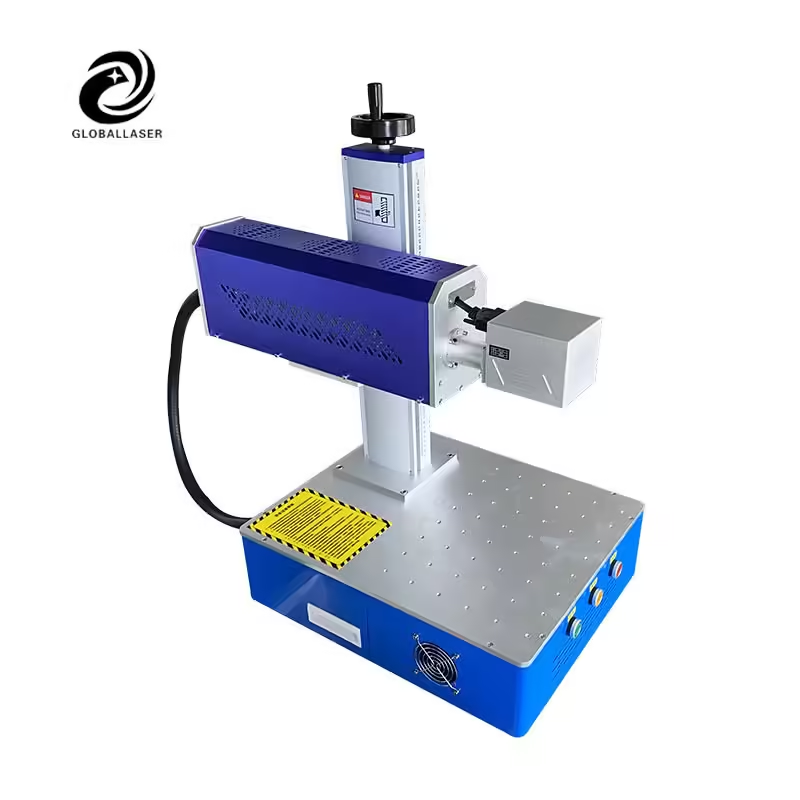

Precision Equipment: China Laser Marking Machine

Table of Contents

Introduction

In today’s competitive manufacturing world, precision and efficiency are the keys to success. Whether you’re engraving metal components, marking electronic parts, or customizing tools, the demand for high-speed and accurate marking has never been greater. That’s why more global buyers are turning their attention to the China laser marking machine market.

China has rapidly become a powerhouse in laser technology, offering machines that combine performance, reliability, and affordability.

If you’re looking to improve your marking process or expand your production line, this guide will help you understand why a China laser marking machine could be your smartest investment.

Why Choose a China Laser Marking Machine

Choosing a laser marking machine from China isn’t just about saving money — it’s about getting global-level precision, stable performance, and technical innovation from a country that has become a manufacturing leader.

Here are the key reasons why international buyers trust Chinese laser machines:

1. Advanced Laser Technology

China’s laser industry has experienced rapid development over the last decade, integrating advanced optical systems, high-speed galvanometers, and precision control software. Many Chinese brands now produce fiber laser marking machines that rival those from Europe and Japan in terms of accuracy and durability.

2. Competitive Pricing with High Value

Compared with Western brands, Chinese laser marking machines offer up to 30–50% lower cost while maintaining similar or even higher output quality. This cost advantage allows businesses to invest in multiple machines or scale up production without breaking their budget.

3. Wide Range of Models and Applications

From compact desktop units for small-scale engraving to industrial-grade fiber laser systems for mass production, Chinese manufacturers provide a full range of laser marking equipment suitable for various materials, including metals, plastics, leather, ceramics, and wood.

4. Reliable After-Sales Support

Top Chinese suppliers now offer global after-sales services, online diagnostics, and video training, ensuring that overseas clients receive technical support quickly and conveniently.

5. Proven Export Experience

According to market data from Laser Focus World (2024), China accounts for over 40% of global laser equipment exports, proving that international buyers trust Chinese-made systems for their production lines.

Key Features and Advantages of China Laser Marking Machines

When you invest in a China laser marking machine, you gain access to the latest in optical precision and automated marking control. Below are some core advantages you’ll appreciate:

- High precision marking: Achieve detailed engravings up to 0.01mm accuracy.

- Non-contact processing: Prevents damage to the surface while ensuring clean results.

- Long service life: High-quality fiber sources can last over 100,000 hours.

- Energy efficiency: Lower power consumption compared to traditional engraving tools.

- User-friendly operation: Intuitive software compatible with various design formats (DXF, PLT, AI, etc.).

- Maintenance-free design: Requires minimal maintenance thanks to stable optical components.

Applications Across Industries

A China laser marking machine can be applied across numerous industries thanks to its ability to mark a wide variety of materials. Here are some popular use cases:

1. Metal and Tool Manufacturing

For marking serial numbers, barcodes, and traceability codes on metals like stainless steel, aluminum, and brass.

2. Electronics and Semiconductors

Perfect for precision marking on delicate electronic components without causing heat distortion.

3. Automotive and Aerospace

Ideal for durable, permanent part identification, including VINs and safety labels.

4. Medical Devices

Used for marking surgical instruments and medical components that require sterilization-resistant markings.

5. Jewelry and Gift Customization

High-precision engraving allows for detailed patterns, names, and logos on jewelry, wooden gifts, and decorative items.

6. Packaging and Branding

Laser logos and codes can be applied to paper, plastics, or wood for anti-counterfeiting and brand differentiation.

How to Choose the Right China Laser Marking Machine

Choosing the best laser marking machine depends on your material type, production volume, and marking requirements.

Factors to Consider

- Material compatibility – Fiber lasers are ideal for metals, while CO₂ lasers are better for non-metals like wood or leather.

- Marking depth and speed – Adjust based on the texture and hardness of your material.

- Work area size – Ensure the marking bed fits your product dimensions.

- Software flexibility – Check for compatibility with CAD and graphic design formats.

- Supplier reliability – Always choose a supplier with export experience, technical certification (ISO, CE), and strong customer feedback.

Recommended Machine Types

| Type | Best For | Advantages |

|---|---|---|

| Fiber Laser Marking Machine | Metal, steel, aluminum, brass | High precision, low maintenance |

| CO₂ Laser Marking Machine | Wood, plastic, leather, paper | Clean marks, great for organic materials |

| UV Laser Marking Machine | Glass, ceramics, polymers | Cold marking with no material damage |

Conclusion

The China laser marking machine has become a symbol of global manufacturing strength — combining precision, affordability, and innovation. For woodworking, metal processing, jewelry design, and industrial marking, Chinese-made systems now offer the same or better results as international brands at a far more competitive price.

If you want to improve marking efficiency, enhance your product branding, and reduce production costs, investing in a China laser marking machine is your next step toward success.

Contact us today to get expert recommendations and a free quotation for your ideal laser marking solution.

FAQ

Are China’s laser marking machines reliable?

Yes. Leading Chinese manufacturers use imported laser sources and quality optical components. Many models meet international standards such as CE and ISO certifications.

What kind of support can I expect after purchase?

Top Chinese suppliers provide global technical support, online troubleshooting, and spare parts service. Training videos and installation guidance are also available.

How long do laser marking machines last?

A well-maintained fiber laser marking machine can last over 10 years or more than 100,000 working hours.

Can I request customization for my production needs?

Absolutely. Chinese manufacturers often offer custom options for laser power, marking area, automation integration, and software language settings.

How soon can I receive my machine after ordering?

Delivery times typically range from 7–20 days, depending on configuration and customization requirements.