Table of Contents

Introduction

In the world of woodworking, precision, speed, and consistency are paramount. As wood products evolve to meet consumer demand for personalized, intricate designs, woodworking manufacturers need reliable, cutting-edge tools to stay ahead. This is where CO₂ laser marking machines for wood come in, offering an efficient, versatile solution for engraving, etching, and personalizing wood surfaces.

Whether you’re producing high-end furniture, custom cabinetry, or decorative wooden signs, a CO₂ laser marking machine provides the level of precision and detail that traditional methods can’t match. This article explores why woodworking manufacturers are increasingly turning to this advanced technology and how it can enhance their business operations.

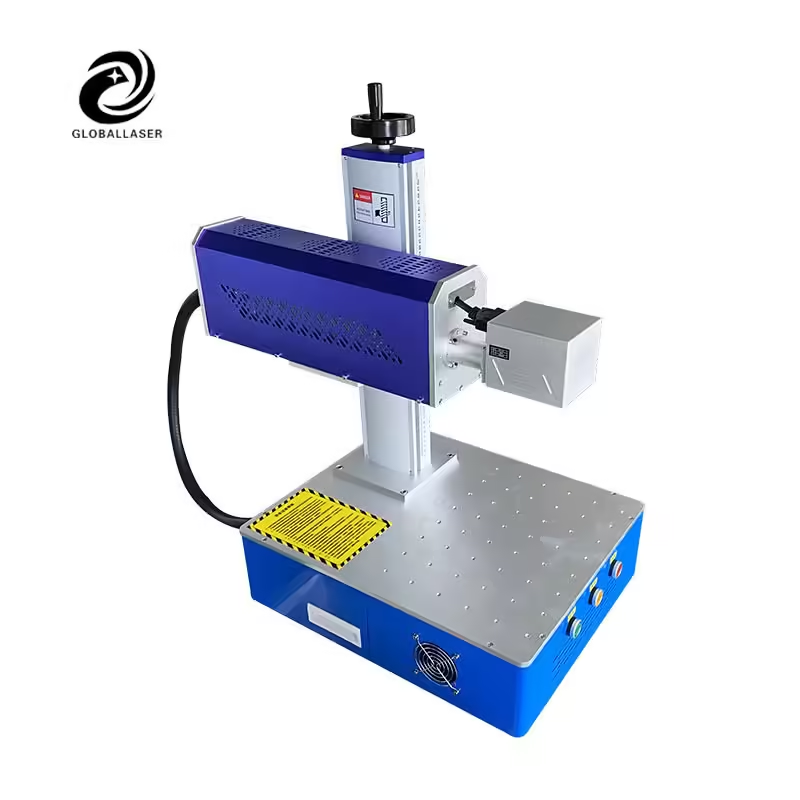

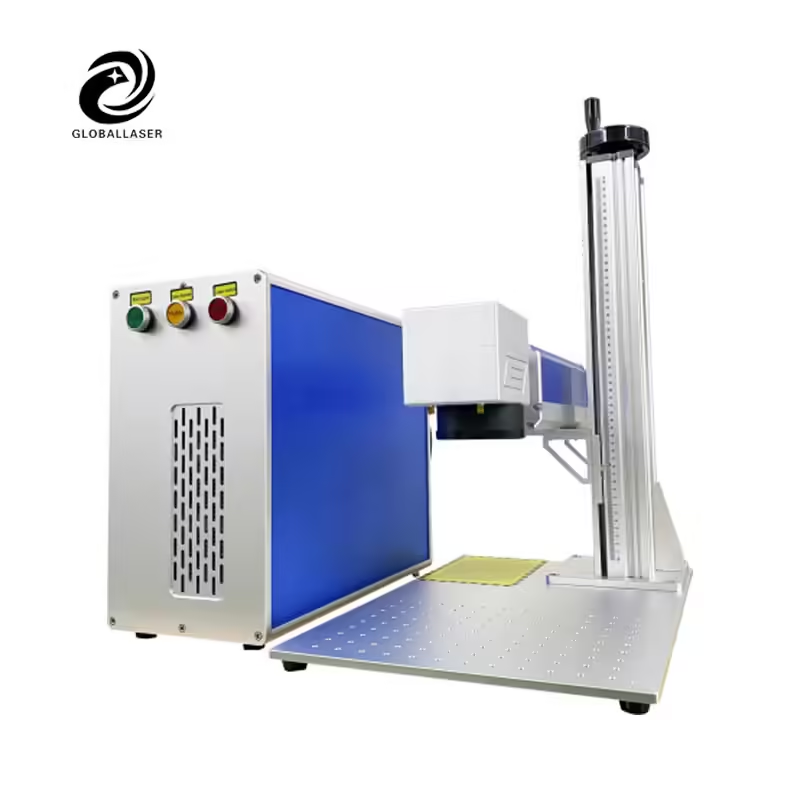

How CO₂ Laser Marking Machines Work for Wood

A CO₂ laser marking machine uses a focused laser beam to vaporize the surface layer of the material, in this case, wood. By adjusting the speed, power, and frequency of the laser, operators can achieve varying depths and shades, allowing for intricate and detailed engravings.

Key aspects of CO₂ laser marking on wood include:

- Non-contact process: The laser beam doesn’t physically touch the wood, preventing the material from being damaged and ensuring precision marks.

- Customizable settings: Adjust the power, speed, and frequency for different effects, from deep engravings to shallow surface designs.

- Minimal waste: As the process only vaporizes a thin layer of the wood, it minimizes material wastage compared to traditional cutting or carving.

This technology not only offers precision but also allows for faster turnaround times, making it ideal for mass production or small-scale, custom orders.

Benefits of CO₂ Laser Marking Machines for Woodworking Manufacturers

1. Unmatched Precision and Detail

When creating intricate designs, from logos to patterns, traditional methods like carving or stamping can be inconsistent. A CO₂ laser marking machine ensures that each engraving is sharp, crisp, and consistent, even for the most complex designs. This precision is especially crucial when working with premium wood products, where detail matters to consumers.

2. Increased Production Efficiency

Unlike manual engraving or carving, which can be time-consuming, laser marking is a faster, automated process. Woodworking manufacturers can significantly speed up production, particularly for bulk orders, while still maintaining high quality. For example, large batches of custom-engraved furniture pieces or personalized wooden gifts can be processed quickly without sacrificing accuracy.

3. Cost-Effective Solution

While the initial cost of a CO₂ laser marking machine for wood may seem high, the long-term savings are substantial. The laser requires minimal maintenance, doesn’t need frequent tool replacements like traditional engraving methods, and reduces waste. Over time, this technology pays for itself by streamlining workflows and cutting down on material costs.

4. Enhanced Design Flexibility

A CO₂ laser engraver opens up a wide array of design possibilities. Manufacturers can easily engrave logos, barcodes, serial numbers, or even custom artwork onto the wood. Whether you’re creating furniture with intricate detailing or personalized signage, the laser can achieve designs that would be difficult or impossible with manual methods. Additionally, the technology supports the use of various wood types, making it highly versatile.

5. Eco-Friendly and Sustainable

In a world where sustainability is more important than ever, CO₂ laser marking machines are an eco-friendly choice. The process generates minimal waste and doesn’t require harsh chemicals, which are often used in traditional wood processing methods. By using a laser engraver, manufacturers can meet sustainability goals and appeal to eco-conscious consumers.

Key Applications of CO₂ Laser Marking Machines for Woodworking Manufacturers

1. Furniture Production

Custom engravings on wooden furniture—such as logos, patterns, or even family names—can increase product appeal. CO₂ lasers enable the creation of intricate designs on any part of the furniture, from chairs and tables to cabinets. Personalized furniture is highly sought after by consumers, especially for high-end or bespoke products.

2. Cabinetry and Millwork

For cabinetry manufacturers, a CO₂ laser marking machine allows for fine detail marking, such as decorative borders, brand logos, or intricate patterns. It also allows for the engraving of component identification codes to streamline assembly.

3. Wooden Signage and Decor

Wooden signs, whether for businesses, homes, or events, can be customized with precision using a CO₂ laser engraver. Custom engraving on wood offers a premium look that appeals to customers who want unique and personalized décor.

4. Gift and Promotional Products

Personalized wooden gifts—such as photo frames, plaques, or keychains—are in high demand. Woodworking manufacturers can use CO₂ laser marking machines to add names, messages, or logos to these items, catering to customers who are looking for customized products.

CO₂ Laser Marking on Different Types of Wood: Key Parameters

The effectiveness of CO₂ laser marking machines can vary depending on the type of wood being used. Below is a table that illustrates the key parameters for laser marking different types of wood, which will help manufacturers choose the right settings for optimal results.

| Wood Type | Laser Power (W) | Speed (mm/s) | Engraving Depth | Recommended Settings |

|---|---|---|---|---|

| Pine | 40-60 | 200-300 | Shallow (0.1 – 0.3mm) | Low power, high speed |

| Oak | 50-80 | 150-250 | Medium (0.3 – 0.6mm) | Moderate power, moderate speed |

| Maple | 60-90 | 100-200 | Deep (0.4 – 0.8mm) | High power, low speed |

| Walnut | 40-70 | 150-250 | Shallow (0.2 – 0.4mm) | Low power, high speed |

| Birch Plywood | 30-50 | 250-350 | Very shallow (0.1mm) | Low power, high speed |

This table provides an overview of the optimal settings for different types of wood, allowing manufacturers to fine-tune their CO₂ laser engraver for maximum efficiency and high-quality results.

Key Factors to Consider When Choosing a CO₂ Laser Marking Machine for Wood

1. Laser Power and Speed

For woodworking, the power of the laser should be chosen according to the thickness of the wood and the desired engraving depth. Machines with adjustable power allow manufacturers to work with different types of wood and achieve varying levels of detail. The speed of the machine also affects production times; faster machines allow for high-volume production while maintaining quality.

2. Size and Workspace Requirements

Consider the size of the workpiece you’re planning to engrave. If you’re working with larger wooden panels, ensure that the machine you choose has a large enough bed to accommodate your pieces.

3. Ease of Use and Software Integration

A CO₂ laser marking machine should come with user-friendly software that allows for easy design integration. The ability to quickly upload and manipulate designs ensures that manufacturers can efficiently process orders and make adjustments as needed.

4. Maintenance and Longevity

Choose a machine that offers easy maintenance and long-lasting performance. Lasers with low maintenance requirements and a durable design reduce downtime and repair costs, which is essential for maintaining productivity.

Conclusion

Incorporating a CO₂ laser marking machine for wood into your woodworking operations is a game-changer. The precision, speed, and versatility these machines offer are unmatched by traditional engraving methods. Whether you’re creating custom furniture, engraved signs, or personalized gifts, a CO₂ laser engraver will elevate your product quality and streamline your production process.

Ready to take your woodworking business to the next level? Contact us today to explore the best laser marking solutions tailored to your needs.

FAQ

Can a CO₂ laser engraver work with all types of wood?

Yes, CO₂ laser marking machines are highly versatile and can work with various types of wood, including softwoods, hardwoods, and plywood. However, different wood types may produce different results, so it’s important to adjust the settings accordingly.

How deep can a CO₂ laser engrave into wood?

The depth of engraving depends on the laser power and the number of passes. Typically, CO₂ lasers can engrave depths ranging from 0.1 mm to several millimeters, depending on the material’s density and the design.

Is it necessary to use any chemicals or finishes after engraving?

No, CO₂ laser marking doesn’t require chemicals or finishes. The process is clean and results in sharp, high-quality marks that don’t require additional treatments. However, some manufacturers may choose to apply finishes to enhance the appearance or protect the wood.

Can a CO₂ laser be used for both engraving and cutting wood?

Yes, CO₂ lasers can both engrave and cut wood. The same machine can switch between engraving designs and cutting out shapes or pieces, making it a versatile tool for woodworking.