CO2 Laser Engraving Machine Comparison Guide

Table of Contents

Introduction

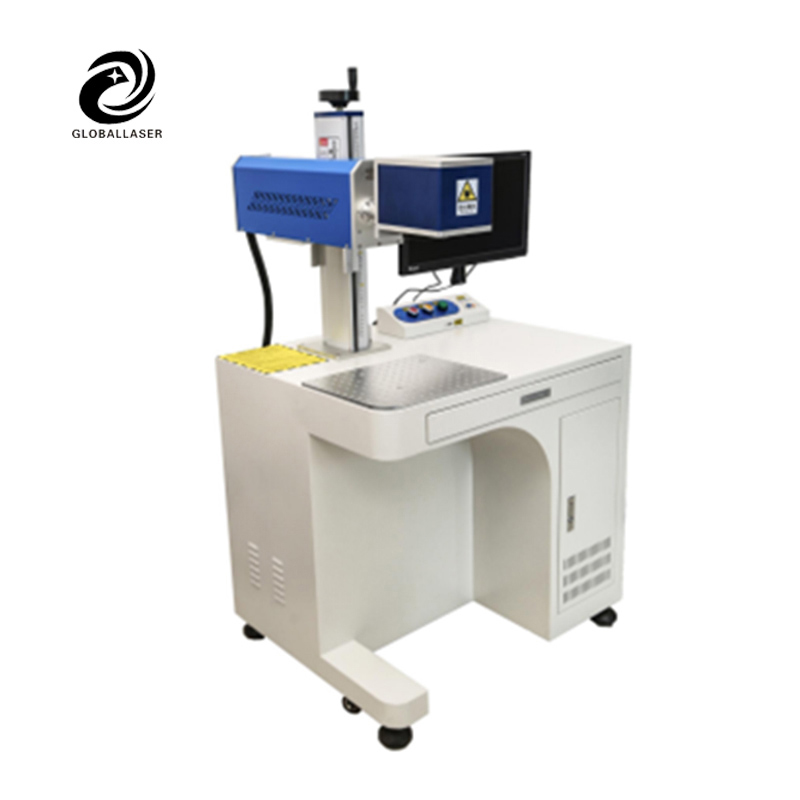

Choosing the right CO2 laser engraving machine can make all the difference in productivity, precision, and project results. Whether you are a small workshop, a craft studio, or a growing business producing signage, décor, or packaging materials, selecting the correct model size—3020, 4060, or 6090—is crucial for meeting your production needs efficiently.

Each CO2 laser engraving machine model has its unique advantages in terms of working area, laser power, cutting depth, and overall versatility. In this detailed comparison, we’ll help you understand the differences and find the perfect balance between performance, cost, and workspace requirements.

What Is a CO2 Laser Engraving Machine?

A CO2 laser engraving machine uses a carbon dioxide gas mixture as the laser source, typically emitting light at a 10.6 μm wavelength. This wavelength is particularly effective for organic materials such as wood, acrylic, leather, paper, and glass.

The laser beam vaporizes the surface of the material, leaving behind sharp, clean engravings or cuts. Because it’s a non-contact process, it avoids mechanical stress and ensures high-quality detail across a wide range of materials.

Common Applications

- Custom signage and advertising displays

- Personalized gifts and crafts

- Packaging and product branding

- Leather cutting and engraving

- Acrylic cutting and edge polishing

Comparing CO2 Laser Engraving Machine Models

Each model number (3020, 4060, 6090) refers to the working area dimensions in millimeters. For example, a 3020 machine provides a 300×200 mm workspace, while the 6090 model offers a much larger 600×900 mm bed.

Comparison Table: CO2 Laser Engraving Machine Models

| Model | Working Area (mm) | Laser Power (W) | Suitable Materials | Ideal User Type | Typical Use Case |

|---|---|---|---|---|---|

| 3020 | 300×200 | 40–50 | Wood, leather, paper, rubber | Hobbyists & small studios | Jewelry, nameplates, crafts |

| 4060 | 400×600 | 60–80 | Wood, acrylic, leather, plastic | SMEs & creative workshops | Signage, décor, batch production |

| 6090 | 600×900 | 80–100 | Acrylic, wood, fabric, MDF | Industrial users & factories | Large panels, furniture, prototypes |

Detailed Overview of Each Model

1. CO2 Laser Engraving Machine 3020

The 3020 CO2 laser engraving machine is the smallest and most compact model, perfect for entry-level users or limited workspaces. Despite its size, it delivers excellent precision for fine details and lightweight materials.

Advantages:

- Compact size and affordable price

- Perfect for small projects and prototypes

- Easy to install and operate

Limitations:

- Limited engraving area

- Lower laser power restricts thicker material cutting

Best for:

Hobbyists, students, and small craft shops producing personalized gifts, labels, or ornaments.

2. CO2 Laser Engraving Machine 4060

The 4060 CO2 laser engraving machine strikes a balance between size and performance. It offers a larger work area and higher power, making it suitable for small businesses handling daily production tasks.

Advantages:

- Increased power for deeper engraving and cutting

- Supports thicker materials like acrylic or plywood

- Compatible with rotary attachments for cylindrical objects

Limitations:

- Requires moderate workspace

- Slightly higher operating cost than 3020

Best for:

Small and medium enterprises producing signage, décor pieces, leather goods, and promotional products.

3. CO2 Laser Engraving Machine 6090

The 6090 CO2 laser engraving machine is a professional-grade model designed for industrial applications. With a large working area and higher power output, it can handle bigger materials and continuous production.

Advantages:

- Supports large-format materials and batch processing

- High precision at high speed

- Compatible with automation upgrades

Limitations:

- Higher initial cost and larger footprint

- Requires stable power supply and ventilation system

Best for:

Factories, furniture makers, or industrial users producing large acrylic panels, MDF boards, or wood signage.

Which CO2 Laser Engraving Machine Should You Choose?

Choosing the right model depends on several key factors:

1. Project Size and Material Type

- For small crafts and detailed designs, the 3020 is ideal.

- For medium-sized workpieces or mixed materials, choose the 4060.

- For large signage, panels, or high-volume production, the 6090 is the best choice.

2. Production Volume

If you plan occasional use or customization on demand, a compact system like the 3020 or 4060 is sufficient. For continuous production lines, 6090 or higher models deliver better long-term value.

3. Budget and Space

The smaller models are more affordable and portable, while the larger ones offer greater productivity. Always balance your workspace capacity with expected return on investment.

Power and Performance Comparison

| Feature | 3020 Model | 4060 Model | 6090 Model |

|---|---|---|---|

| Laser Tube Power | 40–50 W | 60–80 W | 80–100 W |

| Engraving Speed | Up to 300 mm/s | Up to 500 mm/s | Up to 600 mm/s |

| Max Cutting Depth | 3 mm | 6 mm | 10 mm |

| Cooling System | Air-cooled | Water-cooled | Water-cooled |

| Software Support | LaserDRW, CorelLASER | RDWorks, LightBurn | RDWorks, LightBurn |

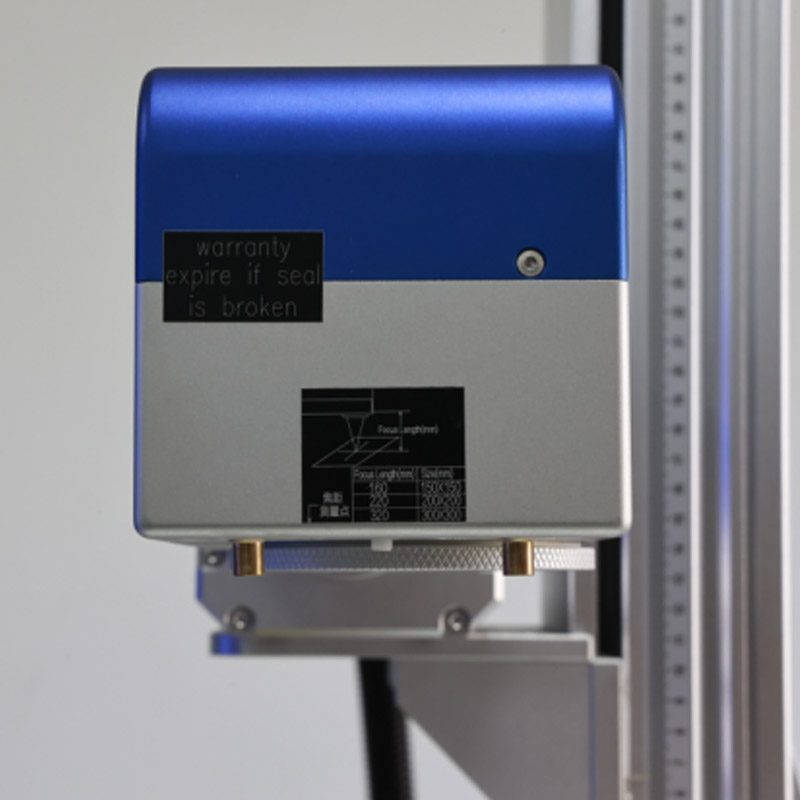

Tips for Selecting the Right CO2 Laser Engraving Machine

- Evaluate your business needs – consider materials, project size, and future expansion.

- Check software compatibility – modern systems like LightBurn offer advanced control.

- Consider accessories – rotary attachments or honeycomb tables can extend functionality.

- Think about maintenance – regular mirror cleaning and lens care ensure consistent performance.

- Safety first – proper ventilation and laser goggles are essential for CO2 laser operations.

Common Materials and Their Engraving Results

| Material | Engraving Result | Recommended Power |

|---|---|---|

| Wood | Dark, high-contrast burn marks | 40–80 W |

| Acrylic | Frosted, smooth edges | 60–100 W |

| Leather | Dark, embossed texture | 40–60 W |

| Glass | Matte surface effect | 60–80 W |

| Fabric | Clean edge, no fraying | 50–60 W |

FAQ

Which CO2 laser engraving machine is best for beginners?

The 3020 model is ideal for beginners because of its compact design, ease of use, and affordable price.

Can the 4060 or 6090 models cut thicker materials?

Yes. Both 4060 and 6090 models offer higher power and can cut materials up to 10 mm thick depending on the laser tube.

What is the difference between water-cooled and air-cooled systems?

Water-cooled systems are better for high-power lasers as they maintain stable temperatures during long operations.

How long does a CO2 laser tube last?

Typically 2,000–3,000 hours for entry-level tubes; industrial models can reach 6,000–10,000 hours.

Do these machines support rotary engraving?

Yes. The 4060 and 6090 models are compatible with rotary attachments for engraving cylindrical objects like bottles or cups.