Exploring Carbon Steel Welding for Heavy Equipment Structures

Table of Contents

Carbon steel welding plays a crucial role in the manufacturing and repair of heavy equipment structures. Whether in the construction, mining, or transportation industries, carbon steel welding is vital for ensuring the strength, durability, and safety of large-scale machinery and infrastructure. In this blog, we will explore how carbon steel welding is used in heavy equipment structures, the challenges faced during welding, and the advanced techniques that improve weld quality and structural integrity.

Heavy equipment, especially large machinery and vehicles, often operates in harsh conditions and is subjected to extreme stress. For this reason, it is essential that the welding process used to join carbon steel components ensures both strength and longevity. Let’s dive into the key aspects of carbon steel welding and its significance for heavy equipment structures.

Why Carbon Steel Welding is Essential for Heavy Equipment Structures

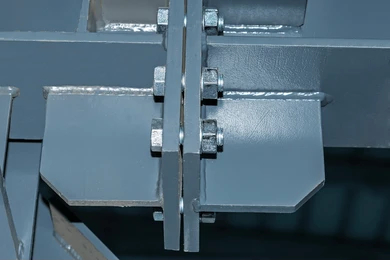

Heavy equipment structures, such as bulldozers, excavators, cranes, and other machinery, are subjected to high stress, vibration, and even extreme temperatures. The strength and durability of these structures rely heavily on the welding process used to join the carbon steel components.

Carbon steel welding is widely used for heavy equipment because carbon steel offers a great balance of strength, hardness, and cost-effectiveness. However, the material’s ability to withstand harsh operating conditions depends largely on the quality of the weld. A poor-quality weld can lead to structural failure, increased maintenance costs, and unsafe operating conditions.

Techniques and Challenges in Carbon Steel Welding for Heavy Equipment

Welding carbon steel for heavy equipment involves various techniques and methods that are tailored to the material’s specific properties and the requirements of the structure being welded. Let’s explore some of the key techniques used in carbon steel welding, along with the challenges associated with each.

1.Thick Plate Welding

Heavy equipment structures often involve thick plate welding, as the components are made from thick carbon steel to withstand heavy loads. Thick plate welding presents unique challenges because thicker materials require more heat to achieve proper penetration, and this can lead to distortion, cracking, and other welding defects.

Carbon steel welding for thick plates requires careful control of heat input and welding parameters. For instance, slower welding speeds and multiple passes are typically needed to ensure uniform heat distribution and prevent overheating. The use of preheating techniques is also common to minimize the risk of thermal stress and cracking.

2.Submerged Arc Welding (SAW)

Submerged arc welding (SAW) is a commonly used technique for carbon steel welding in heavy equipment construction due to its high efficiency and ability to produce deep welds with minimal spatter. In this process, the weld pool is protected by a layer of flux, which helps reduce oxidation and contamination.

SAW is ideal for welding thick sections of carbon steel, and it provides high deposition rates, making it perfect for large heavy equipment components. However, proper flux management and control of the welding speed are essential to ensure that the weld is strong and free from defects.

3.Gas Metal Arc Welding (GMAW)

Gas metal arc welding (GMAW), also known as MIG welding, is another effective method used in carbon steel welding for heavy equipment structures. GMAW is particularly useful for applications where speed and efficiency are essential, as it is a relatively fast welding process that can be used on a wide range of thicknesses.

However, like any welding method, GMAW requires careful control of parameters like voltage, current, and shielding gas to ensure a high-quality weld. For heavy equipment, the quality of the weld is paramount, as even minor defects can compromise the structural integrity of the machine.

4.Controlling Welding Distortion

Welding distortion is a common issue in carbon steel welding, especially when working with thick plates and large structures. Distortion occurs when the material is unevenly heated and cooled, causing the weld area to expand and contract. This can lead to warping, bowing, or misalignment of the components, which can affect the overall performance of the heavy equipment.

To control welding distortion, carbon steel welding must be performed using techniques that minimize the heat input and allow for even distribution of heat across the weld area. Proper joint preparation, such as beveling and tacking, can also help prevent distortion by ensuring that the pieces are aligned correctly before welding begins.

5.Welding Procedure Qualification

Before commencing carbon steel welding on heavy equipment, it’s essential to conduct a welding procedure qualification (WPQ). This process involves testing different welding techniques and parameters to ensure that the chosen welding method produces a strong, durable, and defect-free weld. A WPQ helps establish the right combination of welding materials, heat input, and technique to meet the structural requirements of the heavy equipment being constructed or repaired.

6.Nondestructive Testing (NDT)

Nondestructive testing (NDT) is a critical part of the carbon steel welding process for heavy equipment structures. After welding, it is essential to check the quality and integrity of the weld without causing any damage to the component. Common NDT methods include ultrasonic testing, X-ray inspection, and dye penetrant testing.

These tests ensure that the welds are free from internal defects, such as cracks or voids, which could compromise the safety and functionality of the heavy equipment. Regular NDT inspections are essential in ensuring the long-term reliability of welded structures.

7.Smart Welding Technologies

The advent of smart welding technologies is transforming the way carbon steel welding is performed in heavy equipment manufacturing. These technologies use real-time data and machine learning algorithms to monitor and optimize the welding process, ensuring better weld quality, higher efficiency, and reduced human error.

Smart welding systems can automatically adjust parameters such as voltage, current, and welding speed based on real-time feedback, making the welding process more precise and reliable. This is particularly useful in heavy equipment construction, where the complexity of the structures requires high levels of precision.

Conclusion: Ensuring Strong and Durable Heavy Equipment Structures through Carbon Steel Welding

In conclusion, carbon steel welding plays a critical role in the manufacturing and repair of heavy equipment structures. Whether it’s thick plate welding, submerged arc welding, or gas metal arc welding, each technique requires precision and skill to ensure strong, durable welds that can withstand the harsh environments in which heavy equipment operates.

By implementing the right welding methods, controlling distortion, qualifying welding procedures, and using advanced technologies such as smart welding, manufacturers can achieve high-quality welds that ensure the structural integrity and longevity of heavy equipment.