Blog

Latest Post

Global Laser

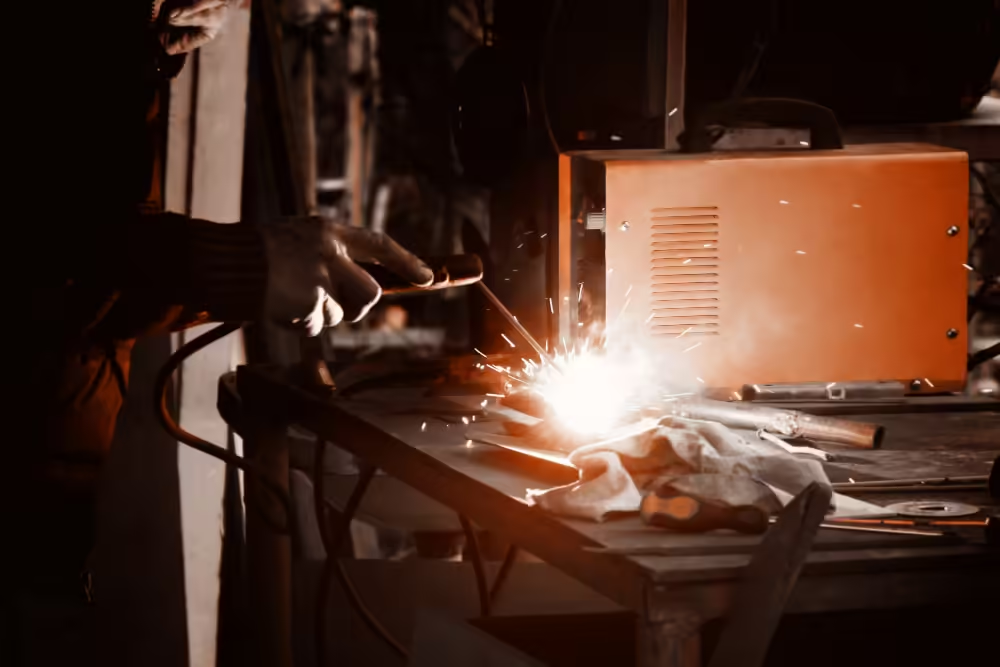

We are committed to providing global customers with laser equipment solutions that exceed their expectations, helping them to improve production efficiency, reduce costs and grow their business, and working with them to create a better future.

Grasp The Industry Trends And Witness global's Development

Here, you can be the first to learn about Global Laser's latest product releases, technological breakthroughs, corporate news, exhibition activities and industry trends. We are committed to sharing cutting-edge laser technology with global customers and jointly exploring the new future of intelligent manufacturing.

Global Service, Responsive At Any Time

If you have any questions, please feel free to contact us and we will answer you as soon as possible. Whether it is products, services or after-sales, just contact us and we will provide you with a satisfactory and thoughtful service experience.