Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576014912000

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

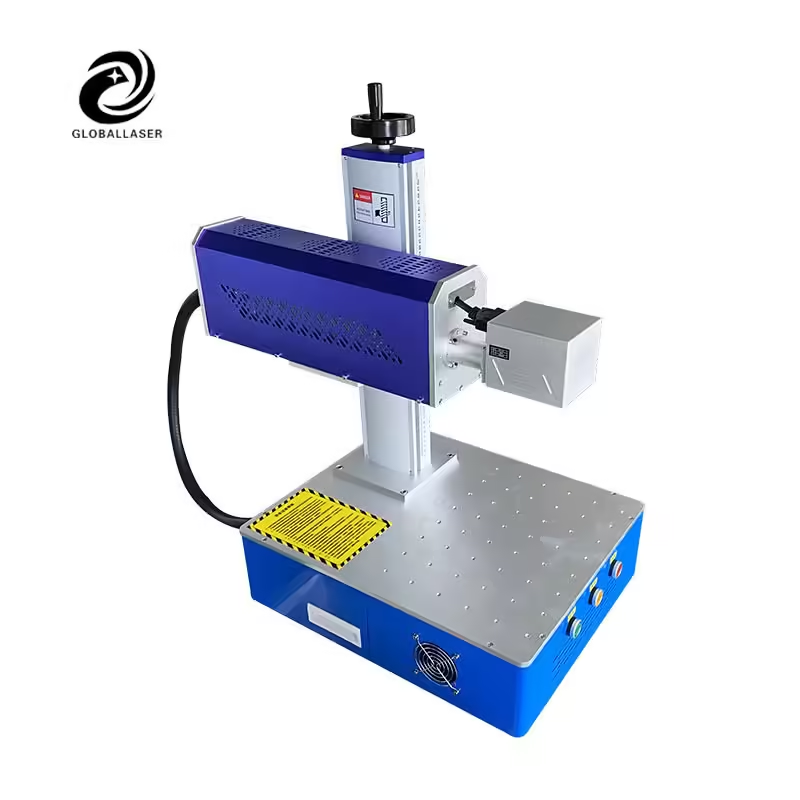

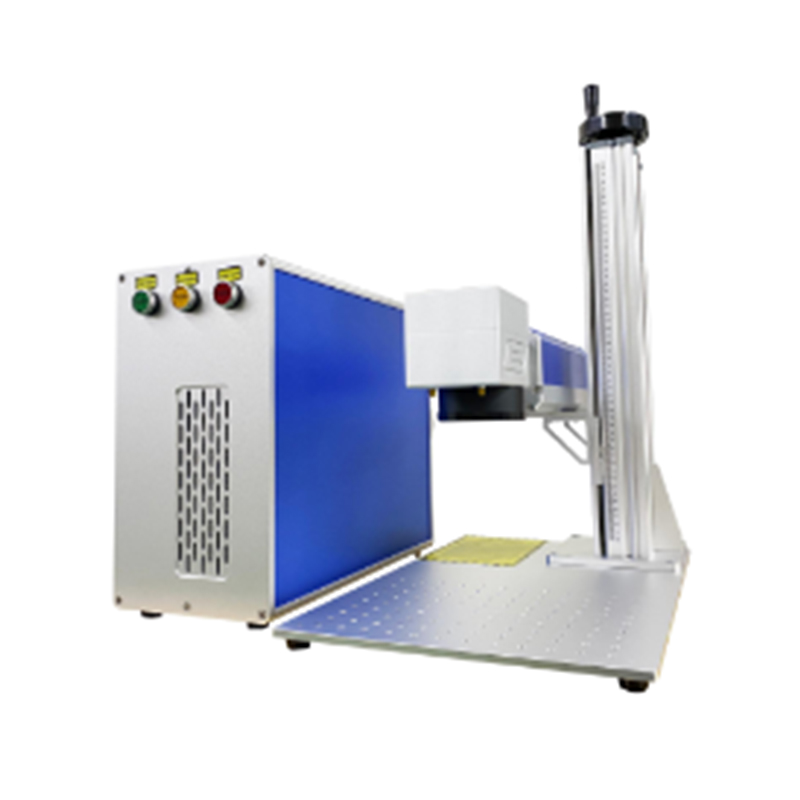

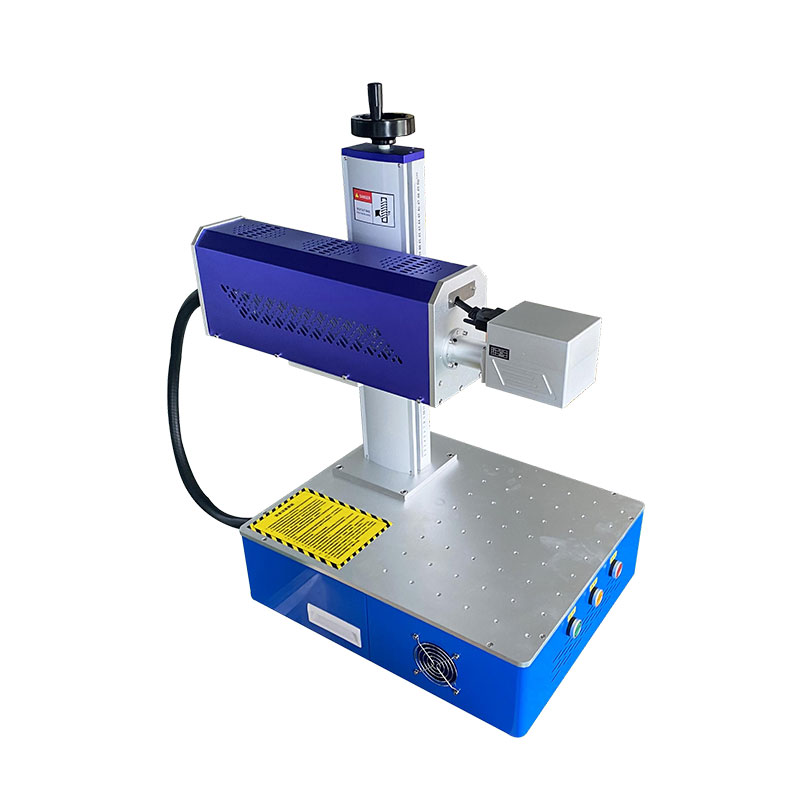

Looking for the best laser marking machine to elevate your production quality? Whether you’re marking metal parts, plastics, or glass, this guide walks you through everything—from technology options to real-world application scenarios—so you can make a confident choice.

Laser Marking Machine Basics

Understanding a best laser marking machine starts with knowing the types available:

Fiber vs CO₂ vs UV lasers

Fiber lasers work wonders on metals and many plastics; CO₂ lasers excel on non-metal surfaces like wood and glass; UV options are perfect for high-contrast marks on heat-sensitive materials.

How power, wavelength, and spot size affect results

Higher power means faster throughput, while wavelength and spot size determine mark depth and precision—critical for intricate designs or traceability codes.

What Makes a Laser Marking Machine the “Best”

Choosing the best laser marking machine means balancing key factors:

- Mark quality and resolution: Clean, permanent, high-contrast marks

- Speed and throughput: Fast enough for your production volume

- Software usability and integration: Easy design import, automation-ready controls

- Durability and service support: Minimal maintenance, responsive after-sales

Comparison Table of Popular Laser Marking Technologies

| Feature | Fiber Laser | CO₂ Laser | UV Laser |

|---|---|---|---|

| Best materials | Metals, painted surfaces | Wood, leather, acrylic | Heat-sensitive plastics, glass |

| Marking speed | Up to 8,000 mm/s | Up to 5,000 mm/s | Up to 4,000 mm/s |

| Minimum mark size | ~0.1 mm | ~0.15 mm | ~0.05 mm |

| Typical use cases | Serial numbers, electronics | Packaging, signage | Medical devices, high-contrast branding |

| Power consumption | Moderate | Higher | Lower |

Choosing the Right Model for Your Needs

- Got metal parts? Fiber lasers give crisp, deep etches.

- Working with packaging or signage? CO₂ is versatile.

- Needing ultra-fine text or fragile surfaces? UV is your go-to.

- Consider build quality: water-cooled for industrial 24/7 use, air-cooled for lighter duty.

Integration & Installation Tips

You’ll want features like USB/Ethernet connectivity, support for vector file formats, and compatibility with third-party automation systems. Proper setup—stable platform, ventilation, correct grounding—is key for consistent performance.

Maintenance & Reliability

Weekly lens cleaning, occasional focus checks, and software updates are all you need. A robust machine can run maintenance-free for thousands of hours with the proper care.

Emerging Trends in Laser Marking

- Faster galvo systems achieving speeds comparable to industrial models

- AI-driven quality monitoring for error-free marking

- IoT-ready features for remote diagnostics and predictive maintenance

Conclusion

Finding the best laser marking machine comes down to matching technology to your target material, production needs, and long-term goals. Fibre, CO₂, or UV—you can get precise, reliable marking without overpaying. Need support with selection or deployment? Our team is ready to help.

FAQ

What materials can the best laser marking machine handle?

Fiber works on metals and coated parts, CO₂ is great for wood and plastics, UV suits plastics and glass too.

Is the mark permanent and durable?

Yes—laser marks resist cleaning, abrasion, and fading.

How fast can it mark?

Depends on the technology: fiber lasers up to 8,000 mm/s, CO₂ around 5,000 mm/s, UV about 4,000 mm/s.

Do I need special training?

Just a few hours to learn the software, safety steps, and focus calibration—after that, it’s smooth sailing.

What about after-sales service?

Look for responsive support and spare parts availability. Closed-box cooling designs tend to need less upkeep.