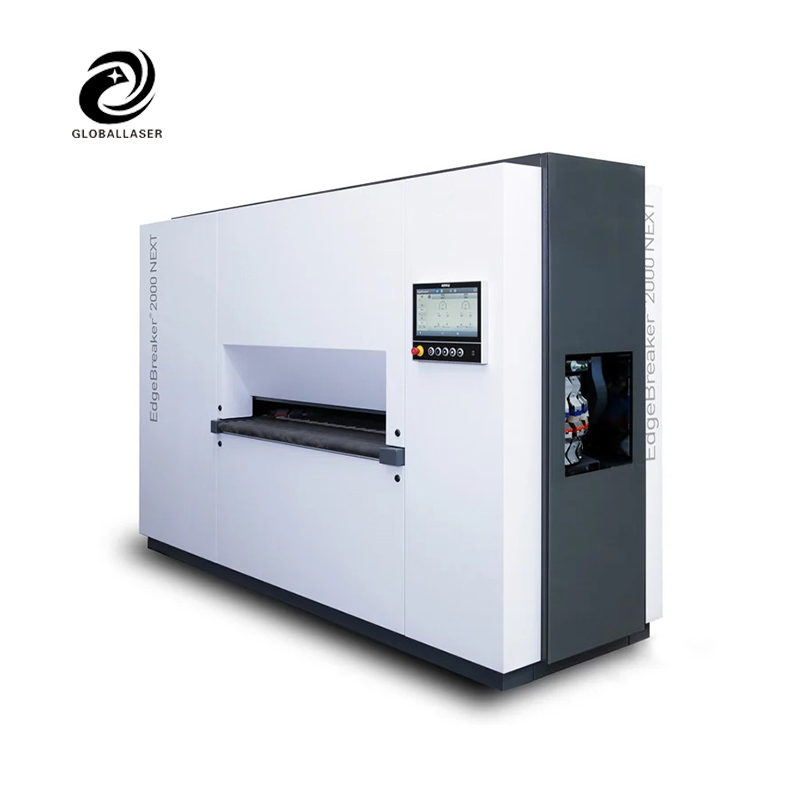

EdgeBreaker® 2000 NEXT

EdgeBreaker® 2000 NEXT

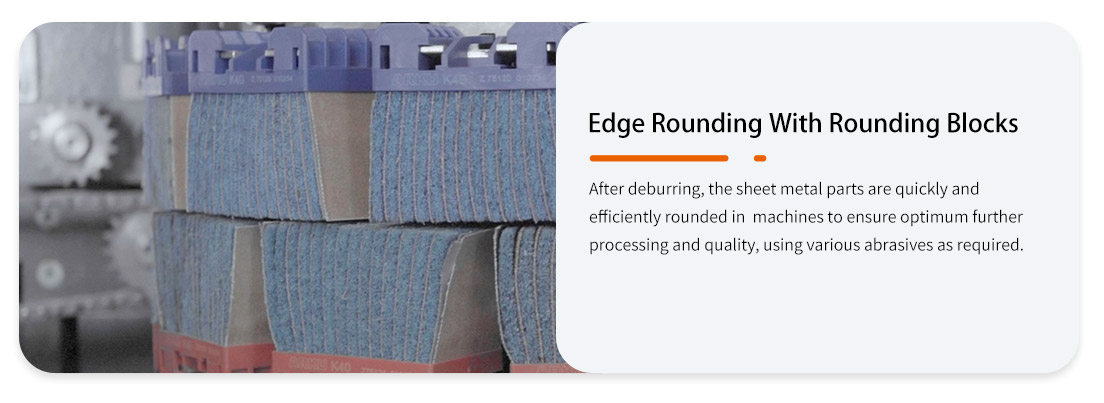

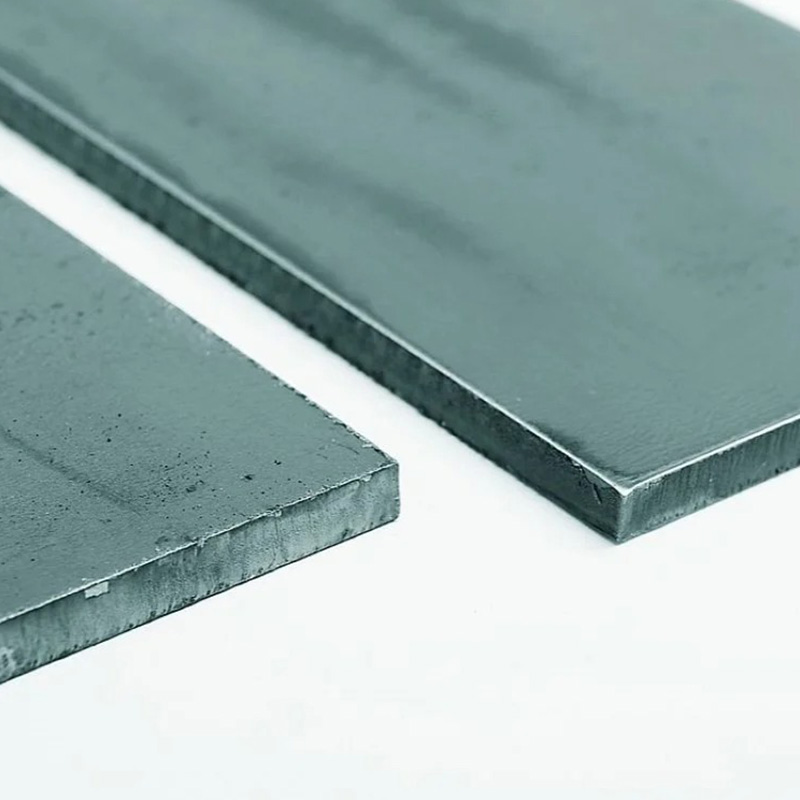

Punched parts or laser cut parts have sharp edges after being cut. The EdgeBreaker® 2000 NEXT is ideal for the necessary double-sided edge rounding: it can remove the sharpness and even remove light burrs all the edges in just a single pass. At the same time, the sheet metal parts are given an attractive surface – an added benefit. As the EdgeBreaker® 2000 NEXT rounds the edges of the sheet metal on both sides, you save an enormous amount of time during production. Thanks to its’ patented click system, you can swap the edge rounding blocks for deburring blocks if needed. Allowing you complete flexibility when it comes to choosing the correct tools (abrasives) within the machine.

Twice the speed for edge rounding and deburring

The EdgeBreaker® 2000 NEXT processes sheet metal parts which are punched or laser cut from both sides simultaneously. This double-sided edge rounding saves more than 50% of the time. These time savings are possible since this deburring machine not only eliminates the need for a second pass, but also the need to remove, flip, and reinsert the parts.

Tool storage for saving processing parameters

If you produce a particular sheet metal part from time to time, you can save the processing settings directly in the machine and call upon the values when required. This allows you to quickly setup the deburring machine for repeat production runs. Thus, avoiding errors during setup.

Consistent results for every part thanks to automatic wear compensation for abrasives

For consistent results, it is essential to always know where you stand. The EdgeBreaker® 2000 NEXT measures the remaining length of your tools (abrasives) within the machine and automatically compensates for the wear off.

Simple operation and maintenance for the deburring machine

The graphical touchscreen interface is easy to operate. It supports you in setting up the machine and provides tips on operation and maintenance. For efficient work without errors!

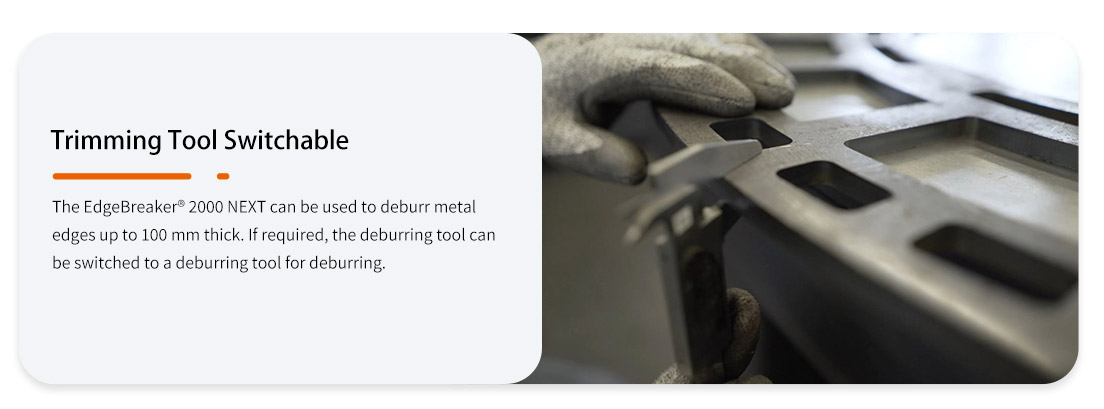

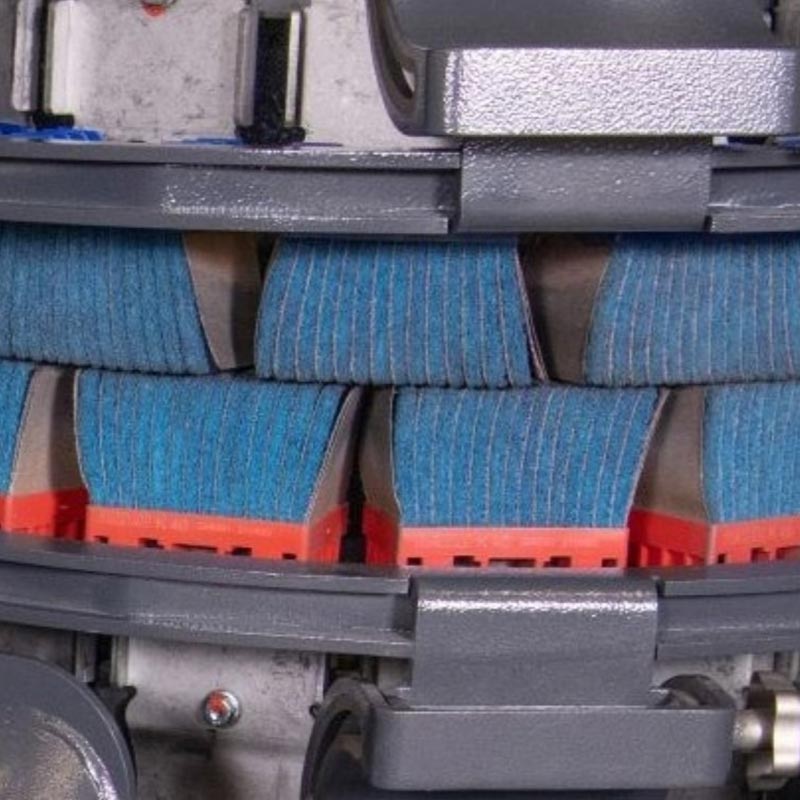

Quick change for edge rounding or deburring tools

All processing units are equipped with a quick-change system for the abrasives to minimize your set-up times. You can simply remove the brushes and click them back in, without any tools needed! The machine can be outfitted with a variety of different tools. All for optimum edge processing to suit your changing requirements.

| Material width | Material width | Material width | |

| 51″ (1,300 mm) | 65″ (1,650 mm) | 79″ (2,000 mm) | |

| Processing type | double-sided, dry | double-sided, dry | double-sided, dry |

| Material thickness | 0.03″ – 4″ (0.8 – 100 mm) | 0.03″ – 4″ (0.8 – 100 mm) | 0.03″ – 4″ (0.8 – 100 mm) |

| Max. working width | 51″ (1,300 mm) | 65″ (1,650 mm) | 79″ (2,000 mm) |

| Weight | approx. 6,400 lbs (2,900 kg) | approx. 8,000 lbs (3,600 kg) | approx. 9,700 lbs (4,400 kg) |

| Dimensions (L x W x H) | approx. 122″ x 59″ x 87″ (3,100 x 1,500 x 2,200 mm) | approx. 134″ x 59″ x 87″ (3,400 x 1,500 x 2,200 mm) | approx. 150″ x 59″ x 87″ (3,800 x 1,500 x 2,200 mm) |