Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576014912000

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

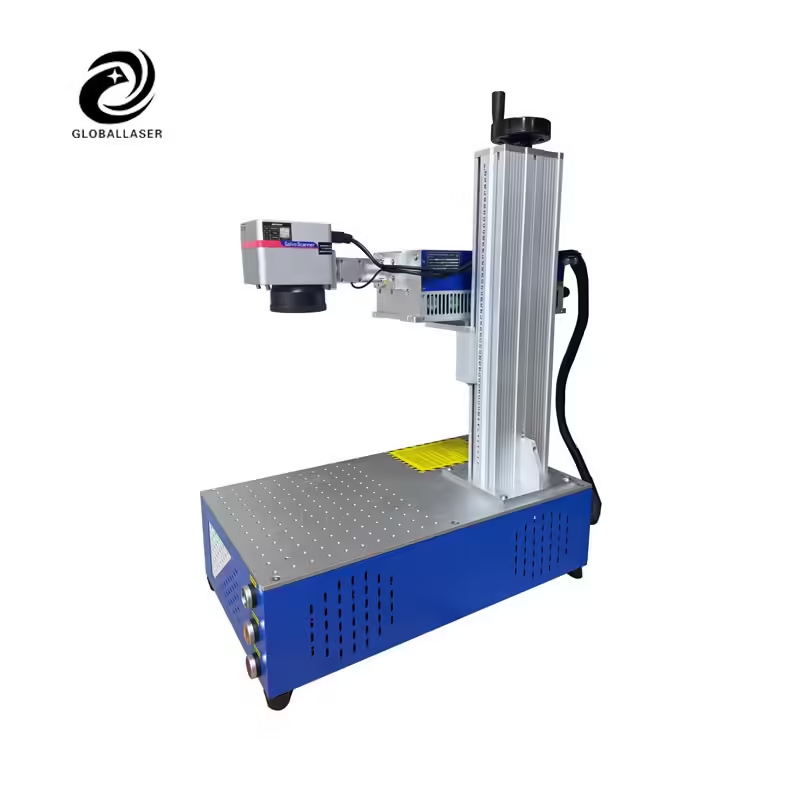

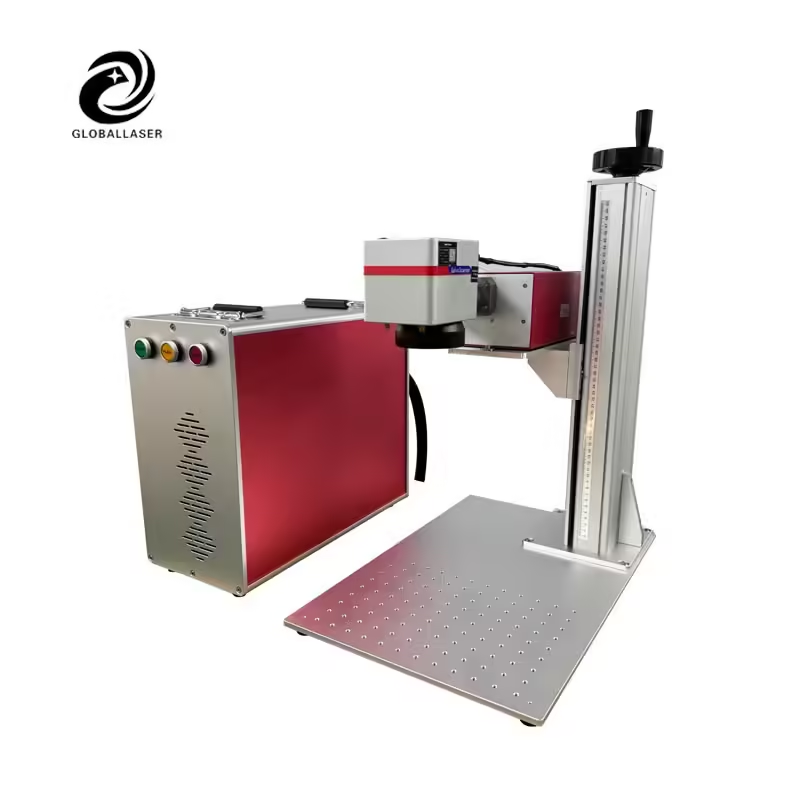

If you’re marking delicate materials—such as glass, ceramics, electronic components, or medical plastics—the right UV laser marking machine is essential. With its cold-marking ability and ultra-fine resolution, UV technology enables precise, high-contrast marks without thermal damage. Understanding what to look for helps you match the machine to your material, throughput, and quality goals.

What Makes UV Laser Marking Technology Unique

UV Wavelength and Cold-Marking Advantage

Unlike infrared lasers, UV laser marking machines operate at around 355 nm—a short wavelength that results in tiny beam spots. This enables superfine marking and minimal heat impact, preserving the integrity of heat-sensitive substrates.

Ultra-Fine Spot Size and Detail Capabilities

With focal spots as small as 20 µm or less, UV systems deliver razor-sharp 2D codes, microtext, serial numbers, or graphics on microelectronic parts or sensor surfaces.

Benefits of Choosing a UV Laser Marking Machine

High Precision and Micro-Mark Capabilities

Perfect for marking tiny elements or branding on consumer goods, a UV laser marking machine offers unmatched clarity and sharpness—essential when tiny fonts or detailed logos are required.

Compatibility with Delicate or Sensitive Materials

From glass instrument panels and ceramic electronics to plastic enclosures and medical-grade polymers, UV marking avoids cracking, charring, or discoloration common with heat-generating lasers.

Permanent, Durable Marks That Last

Marks endure washing, abrasion, chemical exposure, and UV light—ideal for traceability, compliance, or long-term readability.

Fast and Consumable-Free Operation

UV marking systems support high-speed marking without the need for inks, labels, or consumables—minimizing operating cost and line interruptions.

What to Look for When Selecting a UV Laser Marking Machine

Laser Power, Spot Size, and Marking Area

Typical power options range from 3 W to 10 W. Lower power suits fine detail; higher power increases marking speed or depth. Spot size around 20–30 µm ensures high resolution. A common field size ranges up to 300 × 300 mm, ideal for marking boards or panel arrays.

Material and Marking Type Support

Ensure the system handles your material mix: plastics, ceramics, glass, or coated metals. Check that marking formats (text, 2D codes, logos) and software support (file types, auto-alignment, job recall) fit your workflows.

Z-Axis and Surface Height Control

If marking curved or uneven surfaces, look for a UV laser marking machine with motorized Z-axis control or autofocus to maintain consistent focus for precision over 3D parts.

Maintenance, Cooling, and Optics Protection

Air‑cooled systems with sealed optics reduce maintenance needs. Enclosures with dust protection are especially important for dusty environments or sensitive substrate lines.

Application Scenarios Where UV Laser Marking Machine Excels

Electronics and Semiconductor Traceability

On substrates like microchips, PRCs, or PCB components, UV marking ensures fine code readability without impacting signal integrity or material performance.

Medical Devices and Biocompatible Components

Medical-grade plastic tools, sterile disposables, and surgical instruments benefit from permanent, clean, compliant markings—without heat damage or residue.

Glass and Ceramic Products

When marking quartz glass, ceramic motors, or sensor lids, UV lasers generate crisp, matte or frosted effects without inducing micro-cracks or weakening material.

Luxury Goods and High-End Packaging

From textured cosmetic packaging to decorative pen barrels, UV marking enables high-definition logos or serial numbers on UV-absorbing coatings without discoloration.

Comparison Table: UV Laser vs Other Laser Types

| Feature | UV Laser Marking Machine | IR-Based Lasers (Fiber / CO₂) |

|---|---|---|

| Wavelength | ~355 nm (ultraviolet) | 1064 nm or 10.6 µm |

| Heat Impact | Minimal (‘cold marking’) | Higher risk of discoloration or damage |

| Minimum Mark Spot | ~20 µm or less | ~50–100 µm |

| Material Suitability | Plastics, glass, ceramics, electronics | Metals, wood, thicker plastics |

| Mark Durability | Highly resistant | Durable but heat-sensitive on some parts |

| Consumables / Maintenance | Low – air cooled, sealed optics | May need water cooling or lens cleaning |

How to Align Selection with Your Needs

Define Your Marking Materials and Precision Goals

Start by listing your substrates and desired mark type—such as logos, micro text, trace codes, or graphics. That helps target beam power and spot size.

Match Volume and Marking Speed Expectations

For high-volume production, prioritize laser systems with higher focal speeds, greater power, and repeatable precision. For prototyping or low volume, bench-top units often suffice.

Ensure Future-Proof Integration Options

Choose machines with modular features—such as rotary axes, Z-axis adjustments, or automation interfaces—to support future marking of curved or varied products.

Software and Format Compatibility

Confirm support for popular output formats (BMP, DXF, SVG) and workflow capabilities like autofocus, marking job libraries, or auto code generation.

Maintenance and Safety Best Practices

Routine Cleaning and Calibration

Keep lens surfaces clear of dust and periodically recalibrate alignment to preserve mark quality and minimize machine downtime.

Laser Safety Measures

Adhere to safety standards; opt for Class 1 enclosure systems where possible. For open systems, use laser curtains, interlocks, and proper signage to ensure a safe workspace.

Monitoring and Diagnostics Features

Some UV laser marking machines include laser power monitors and beam diagnostics—helping detect output drift early for predictive maintenance and downtime management.

Conclusion

Choosing the right UV laser marking machine comes down to selecting a system that matches your substrate mix, desired mark style, throughput needs, and integration plan. With unparalleled precision, minimal thermal impact, and high durability, UV marking solutions excel for electronics, medical devices, glass, ceramics, and premium coated surfaces.

If you’re ready to implement or upgrade your laser marking line, our team offers expert guidance, system selection help, and turnkey support. Contact us today to discuss your marking applications and find the ideal UV laser solution for your needs.

FAQ

Why is a UV laser marking machine better than infrared systems?

Because UV lasers produce ultra-fine, high‑contrast marks without overheating substrates—ideal for fragile or sensitive materials.

Can UV marking damage glass or ceramics?

No—cold, low-heat UV technology allows safe marking on these materials without causing micro-cracks or heat distortion.

Is maintenance demanding?

Typically not—air-cooled designs with sealed optics require minimal upkeep. Predictive power monitoring helps prevent unexpected failures.

What power range should I consider?

3–5 W is sufficient for micro-detail work; 7–10 W offers faster marking and greater depth for batch high-volume needs.

Can UV marking work on coated or reflective surfaces?

Yes—against absorbent or coated plastic surfaces, UV lasers deliver crisp, contrasting marks. Reflective metal marking is also possible in some cases.