Fiber Laser Marker Machine: Speed & Durability

Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576014912000

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

In today’s fast-paced cable tray industry, precision and durability aren’t optional—they’re essential. As demands increase for high-volume, high-accuracy production, the fiber laser marker machine has become an indispensable tool.

What Is a Fiber Laser Marker Machine and How Does It Work?

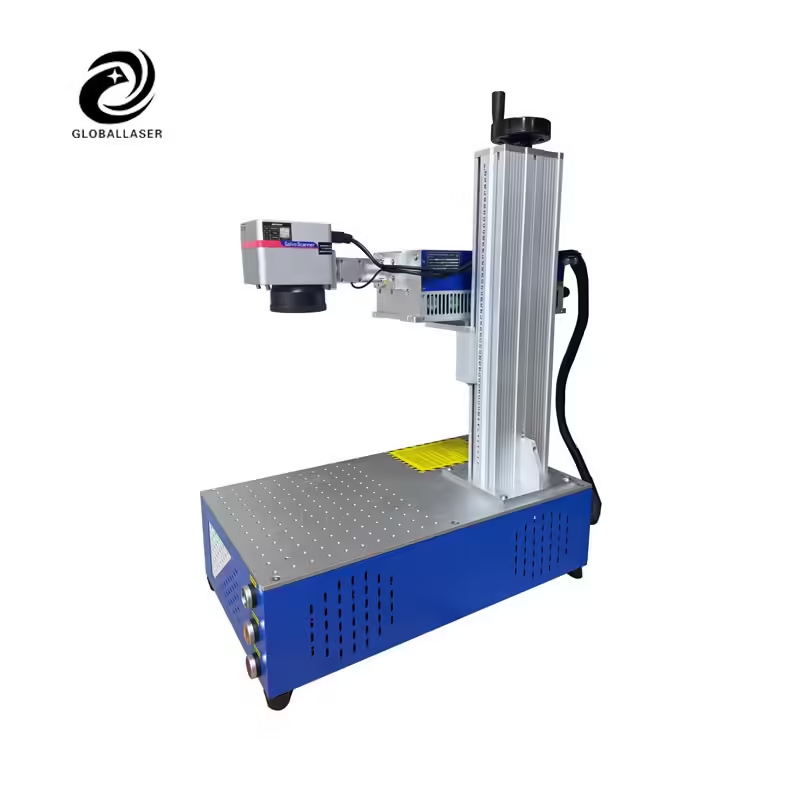

A fiber laser marker machine is a type of industrial laser equipment that uses a fiber laser beam to create permanent marks on metal and plastic surfaces. It operates by emitting a focused, high-energy laser beam that interacts with the surface of a material, causing a color change, oxidation, or etching effect.

Here’s a quick overview of how the machine operates:

- A laser source, typically powered by ytterbium-doped fiber, produces a high-powered beam.

- The beam is directed through a galvo head (galvanometer scanner), which rapidly moves it across the material surface.

- The system is controlled via software, allowing precise positioning, depth, and shape of each mark.

Because fiber lasers work without physical contact, there’s minimal wear on the equipment and no deformation of the cable tray surface—making them ideal for maintaining the structural integrity of cable tray systems.

Key Features of Fiber Laser Marker Machines in Cable Tray Production

| Feature | Performance Specification | Relevance to Cable Tray Manufacturing |

|---|---|---|

| Marking Speed | 10,000 – 30,000 mm/s | Enables high-throughput operations without slowing down production |

| Precision | ±0.01 mm | Ensures accurate markings even on narrow flanges or tight bends |

| Material Compatibility | Steel, stainless steel, aluminum | Works across a wide range of cable tray materials |

| Mark Durability | Permanent and corrosion-resistant | Marks withstand harsh environments, humidity, and chemicals |

| Maintenance | Minimal | No consumables, reducing operational downtime |

| Lifespan | 100,000+ hours | Long-term cost savings and machine reliability |

Advantages of Using a Fiber Laser Marker Machine

High-Speed Marking for Large-Scale Production

When you produce hundreds or thousands of products a day that need laser marking, speed is critical. Fiber laser marking machines can mark data such as serial numbers or QR codes in less than a second, helping to maintain productivity without sacrificing accuracy. On high-volume production lines, this means significant labor and time savings.

Superior Marking Quality

Unlike inkjet or mechanical methods, fiber laser marking is clearly readable even on curved or irregular surfaces. This is critical when dealing with items of varying thickness or shapes. The high beam quality produces crisp lines, ensuring every product has a professional, clear mark.

Long-Term Durability in Harsh Environments

Some products need to be installed in places where they are exposed to humidity, high temperatures, or chemicals. Labels or stickers tend to fall off over time, and inks can fade. In contrast, laser marking is permanent and corrosion-resistant, ensuring that identification marks remain intact throughout the product’s life cycle.

Flexible Application on Various Tray Types

Whether you are working with round, cuboid or irregular shapes, the fiber laser marking machine can meet your production needs. It can easily handle different shapes and sizes, and its flexible software supports quick changes in marking layout or data.

Environmental and Cost Efficiency

Because it doesn’t rely on inks, solvents, or consumables, a fiber laser marker machine significantly reduces waste and environmental impact. Over time, this leads to lower operating costs and less need for consumable restocking or disposal.

Conclusion

With unparalleled speed, precision and durability, fiber laser marking is not just a tool, but a strategic upgrade that supports you in achieving your goals of quality, traceability, compliance and efficiency.

SDGlobal Laser specializes in laser marking machines to help manufacturers like you streamline processes, reduce errors, and increase product value. Whether you are expanding or upgrading an old marking method, we are ready to assist you in selecting the right solution.

Contact us today to learn how our expertise and fiber laser marking technology can elevate your cable tray manufacturing business.

FAQ

How long does the marking last?

The marking is permanent and can last as long as the product itself. It won’t fade, scratch off, or degrade in harsh environments.

Is it safe to use in a factory environment?

Modern fiber laser systems come with safety features such as enclosures, fume extractors, and interlocks, making them safe for use in industrial settings.

What maintenance is required?

Minimal maintenance is needed. Regular cleaning of lenses and occasional software updates are generally sufficient.

How fast can it mark each tray?

Marking typically takes 1–2 seconds per tray, depending on the complexity and size of the content.