Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576014912000

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

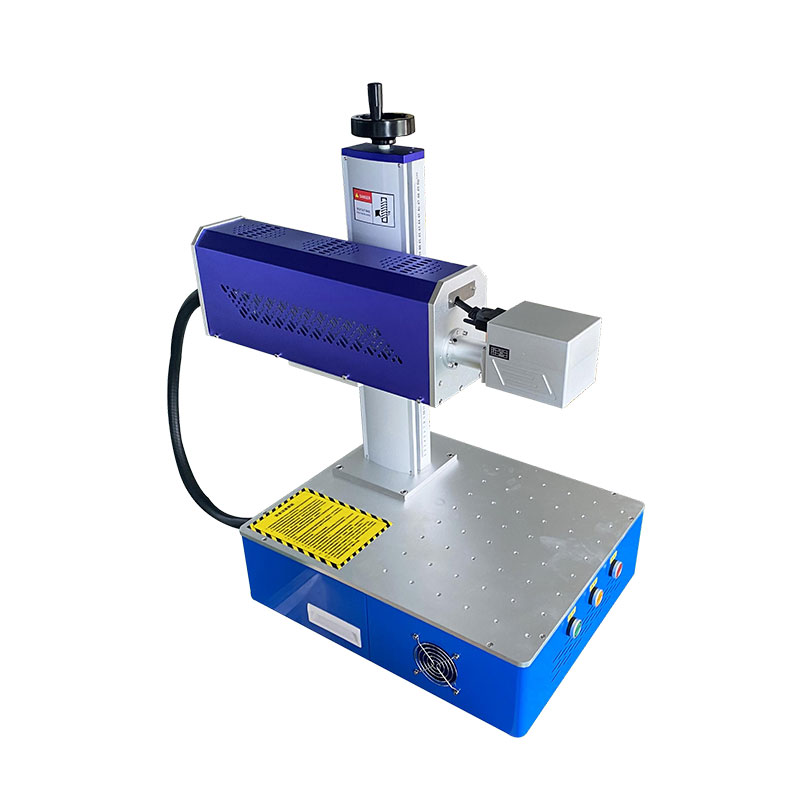

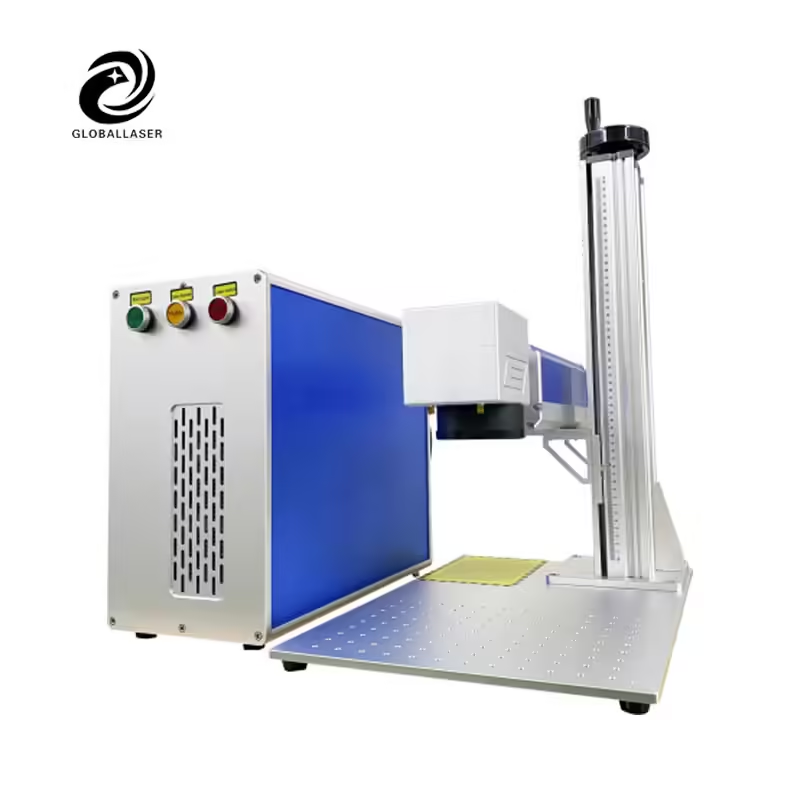

When you work in industrial manufacturing—especially producing products like cable trays—you need precision, durability, and consistency. That’s where a laser machine for marking comes in. A laser marking machine is a specialized tool that uses concentrated light to permanently etch or mark materials with logos, serial numbers, barcodes, or technical data.

In this guide, we’ll walk you through what a laser marking machine is, how it works, why it’s vital for cable tray manufacturing, and how to choose the right setup for your needs.

How Does a Laser Machine for Marking Work?

Fundamental Principles

A laser marking machine uses a high-intensity beam to alter a material’s surface through photothermal or photochemical processes. Common modes include engraving (removing material), annealing (color change without material removal), and etching (shallow marking).

Different laser sources (such as fiber laser or CO₂ laser) suit materials like steel, aluminum, or plastic, which are all encountered in cable tray fabrication.

Why It’s Ideal for Cable Tray Marking

Permanence and Durability: Marks endure extreme industrial environments.

High Precision: Enables marking directly onto ladder rails, sidewalls, or perforations with minimal heat-affected zones.

Speed and Automation: Integrates with conveyor systems for batch production.

Types of Laser Marking Machines Commonly Used for Cable Tray Manufacturing

| Laser Type | Typical Materials | Marking Speed | Precision | Ideal Use Case in Cable Tray Production |

|---|---|---|---|---|

| Fiber Laser | Stainless steel, aluminum | 10,000–30,000 mm/s | High (±0.01 mm) | Serial numbers, specifications etched on tray beams |

| CO₂ Laser | Painted trays, plastics | 5,000–15,000 mm/s | Moderate | Decorative logos, coating removal on pre-painted parts |

| UV Laser | Plastics, coatings | 1,000–5,000 mm/s | Very High | Non-metal marking, labels, and barcodes |

| DPSS Laser | Thin metals, delicate parts | ~5,000 mm/s | High | Marking small or thin brackets without heat distortion |

(Source: Industrial Laser Technology Review, 2024)

Fiber laser marking machines dominate in metalworking—including cable tray production—due to robustness and speed. Reports show manufacturers using fiber laser marking reduced labeling errors by over 60%, based on internal quality control data from a 2023 production line audit.

Why Use a Laser Machine for Marking in Cable Tray Production?

Traceability and Compliance

In cable tray manufacturing, each unit may need trace labels indicating material grade, load capacity, batch number, or production date. Laser marking ensures those marks are permanent and readable, even in harsh conditions.

Efficiency and Automation Capability

You can integrate a laser marking system directly into fabrication lines. As trays exit bending or welding stages, automated marking is completed in seconds—no manual intervention needed.

Reduced Costs and Waste

Unlike ink printing or stickers that can wear or peel, laser marks don’t fade or detach, reducing rework and quality issues. Over time, this means fewer wasted trays or relabeling jobs.

Material traceability and cost savings are well documented: a manufacturing study in 2023 showed laser marking systems cut post-production labeling time by about 50%.

Key Features to Consider When Choosing a Laser Machine for Marking

Power and Wavelength

Fiber lasers (typically around 1064 nm) are ideal for metals like stainless steel and aluminum. CO₂ lasers (~10.6 µm) work well on non-metal surfaces or coatings. UV lasers are useful for plastic marking with minimal surface damage.

Marking Field Size

Ensure your system accommodates tray width and length. Typical cable trays may require marking zones of up to 1,800 mm in width.

Integration and Automation

Look for CNC-compatible or PLC-integrated systems if you plan to automate marking inline with your production. Features like conveyor synchronization and barcode scanning support batch control.

Software and Format Support

Modern laser marking machines support industry-standard formats like DataMatrix, QR codes, and customized text or logos. Software ease-of-use affects operator proficiency and error rates.

Applications of Laser Marking Machines in Cable Tray Industry

Product Identification: Permanent detailing of material type (e.g. “SS304L”), load rating, and manufacturer info.

Traceability Labels: Codes and barcodes linked to digital databases for tracking batch or quality history.

Safety Instructions: Etching guidelines or warnings directly onto cable tray surfaces near edges or drop-outs.

Custom Logo and Branding: A polished, professional appearance with laser-etched brand marks.

Compliance Markings: Embossing conformity marks or certification symbols that must remain legible for safety audits.

Best Practices for Operating Laser Marking Systems Safely and Efficiently

Ensure Proper Ventilation: Marking may produce fumes or metal particles—use extractor systems or localized ventilation.

Maintain Clean Optics: Mirror and lens cleanliness are critical for beam accuracy and system longevity.

Test on Sample Material: Confirm settings before full-scale production to avoid damaging trays.

Train Operators: Even if automated, knowledgeable technicians ensure consistent marking quality and safety compliance.

Conclusion

A laser machine for marking is a game-changer for industrial fabrication—combining precision, permanence, and automation in ways traditional methods can’t match. For cable tray manufacturers, integrating laser marking yields improved quality control, traceability, and branding consistency.

If you’re producing heavy-duty cable trays and want marks that last, align with regulations, and reduce manual labor, investing in a laser marking system is a smart move.

At Yidian, we specialize in cable tray manufacturing and partner with laser marking solution providers to offer integrated systems that work seamlessly with your production line.

📞 Ready to upgrade your marking process? Contact Yidian for expert advice and industrial-grade laser marking setups tailored to cable tray fabrication.

FAQ

What types of materials can a laser machine for marking handle?

Laser systems—especially fiber lasers—can directly mark metals like stainless steel, aluminum, and galvanized surfaces commonly used in cable tray manufacturing. CO₂ and UV lasers support polymers, coatings, and UV-sensitive parts.

How fast is laser marking compared to other methods?

Laser marking often completes a mark in seconds; batch rates can exceed 1,000 units per hour. It’s typically 10× faster than manual labeling or ink printing methods.

Will a laser machine damage my cable trays?

When properly configured, a laser marking machine causes minimal heat-affected zones and no structural damage. It’s a controlled process designed for industrial-grade metal surfaces.

Can the marked codes be tracked digitally?

Yes. Laser machines support industry-standard formats (QR, DataMatrix). When tied to your ERP or traceability system, each tray becomes instantly verifiable in digital logs.

Is laser marking expensive for small production runs?

Initial setup costs can be higher compared to manual methods. But for consistent production or batch workflows, the reduction in errors, rework, and labor makes it cost-effective—even for modest volumes.