Table of Contents

Introduction

If you’re researching laser marking machine types, you’re probably looking to find the ideal system for engraving, coding, or etching materials in your production or workshop. With options like fiber laser marking systems, CO₂ laser engravers, and UV laser marking for plastics, the choice can get confusing.

According to the 2023 Industrial Laser Equipment Survey, fiber laser markers made up 42% of new equipment purchases globally, thanks to their precision and flexibility. Still, CO₂ and diode laser systems remain strong in specific industries. In this guide, we’ll clarify each laser marking machine type, compare their benefits, and help you choose the best fit for your needs.

Common Laser Marking Machine Types and Their Applications

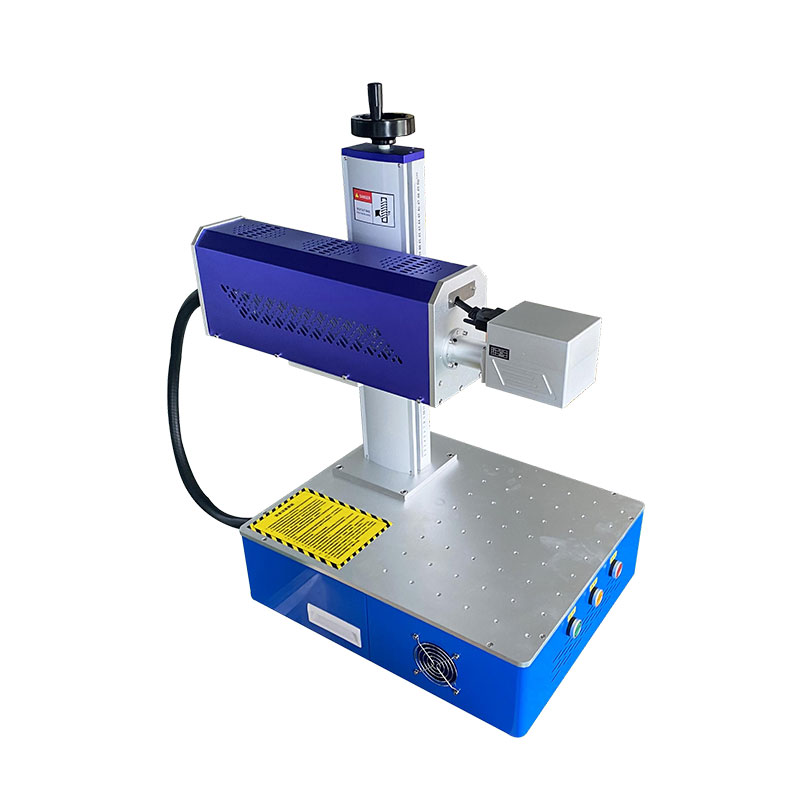

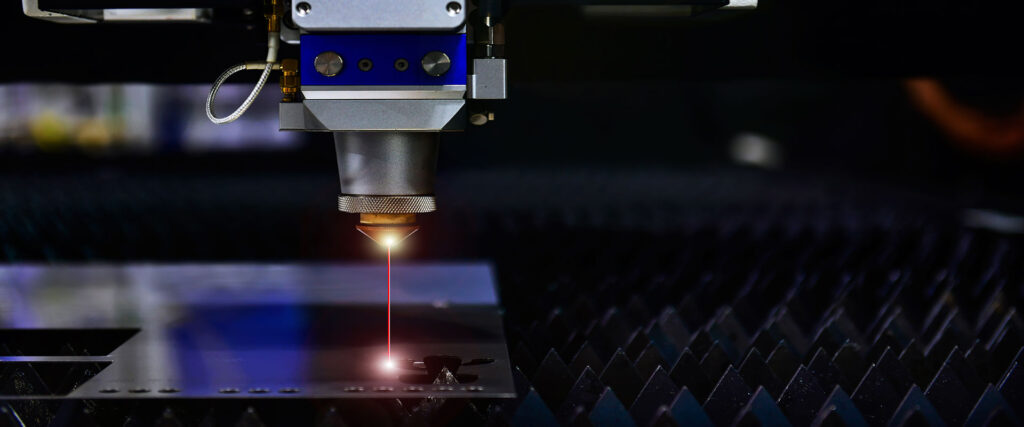

Fiber laser marking systems use a fiber-optic core doped with rare-earth elements to generate laser pulses. They are typically ideal for marking metals, plastics, and ceramics. Applications include serial number plates, medical devices, and automotive components. Fiber lasers offer high-speed marking with tight tolerances, low maintenance (since there is no tube to replace), and good compatibility with hard materials.

CO₂ laser engravers generate infrared laser using a sealed gas mixture. They work well on organic materials such as wood, glass, leather, acrylics, and coated metals. You’ll often find them in signage, decorative paneling, and packaging businesses. They offer deep engraving and are relatively low-cost for entry-level setups.

UV laser marking for plastics operates at ultraviolet wavelengths, enabling photochemical ablation with minimal heat impact. These systems are perfect for heat-sensitive materials like delicate plastics or electronics. They produce crisp, high-contrast marks without generating a heat-affected zone, which is important for medical devices or microelectronics.

Green or DPSS lasers (532 nm wavelength) are used for specialized applications like gemstone marking or certain plastics that absorb green better than infrared. Diode-pumped solid-state options are often used in precision marking scenarios such as jewelry, sensor manufacturing, or circuit boards.

Diode laser coders are more basic and compact, typically used for coding barcodes, lot numbers, and expiry dates. They are low-cost and low-maintenance but limited in depth and speed.

Comparison of Laser Marking Machine Types

| Laser Type | Ideal Materials | Mark Speed | Maintenance Cost | Typical Applications |

|---|---|---|---|---|

| Fiber Laser | Metals, plastics, ceramics | Very High | Low | Automotive, medical, tools |

| CO₂ Laser Engraver | Wood, glass, leather, acrylic | Medium | Medium | Signage, packaging, decorative panels |

| UV Laser Marking | Heat-sensitive plastics, electronics | High | Medium–High | Electronics, medical parts |

| Green/DPSS Laser | Gemstones, specific plastics | Medium | Medium | Jewelry, glassware, sensors |

| Diode Laser Coder | Cardboard, films, basic packaging | Low | Low | Barcodes, expiry, lot marking |

This table helps you evaluate which laser marking machine type aligns best with your materials and production needs.

Choosing Among Laser Marking Machine Types: Key Considerations

First, think about the materials you’ll mark. Metals and durable plastics? Fiber laser is ideal. Organic materials like wood or leather point to CO₂ lasers. Delicate plastics or electronic parts with UV laser needs.

Next, consider production volume and speed. Fiber lasers are designed for high-volume lines, while CO₂ or diode lasers may suffice for lower-throughput scenarios. Maintenance costs matter too—fiber lasers have few moving parts, while CO₂ systems need mirror and tube upkeep. UV and DPSS options require periodic alignment.

Resolution and precision also guide the decision. UV lasers offer sub-micron resolution, ideal for electronics. Fiber lasers give 50–100 micron accuracy, perfect for serial numbers. CO₂ lasers provide decent aesthetic engraving but not high-detail precision.

Safety and integration are also important. CO₂ and diode lasers may require enclosures and exhaust, while fiber and UV lasers can be safer in open environments but may still need safety protocols. Automation needs like rotary axis or conveyor feeding help choose the right system size and integration.

Real-World Examples and Case Studies

In one case, a major automotive parts producer switched from inkjet to fiber laser marking. The result was a 98% reduction in marking errors and elimination of solvent emissions.

An electronics PCB manufacturer switched to UV laser marking, reducing surface heat damage by 55% and increasing throughput by 20%.

A small engraving shop specializing in personalized wood and glass gifts adopted a CO₂ laser engraver and saw a 30% sales increase through same-day customization.

These use cases, documented in the 2023 Laser Processing Review, highlight how choosing the right laser marking machine types can impact productivity and quality.

Tips for Integration and Optimization

To get the most from your laser system:

- Fine-tune beam focus and marking speed for each material.

- Install fume extraction for CO₂ systems when working with organic matter.

- Use fixtures or jigs to ensure consistent part positioning.

- Choose software that supports barcode and serialization formats for traceability.

- Provide operator training on settings, safety, maintenance, and common troubleshooting.

Following these tips leads to more reliable, high-quality marking across various production scenarios.

Conclusion

Understanding laser marking machine types helps you make confident choices. Fiber lasers are the top pick for speed, durability, and metal marking. CO₂ lasers remain strong contenders for signage and decorative markets. UV lasers excel in electronics and heat-sensitive applications. Green and DPSS lasers serve unique niche sectors, while diode laser coders are reliable for simple packaging codes.

By aligning your material, speed, precision, and budget requirements, you can choose a system that boosts reliability, quality, and scalability.

FAQ

What is the fastest laser marking machine type?

Fiber lasers are the fastest and most efficient for high-volume metal and plastic marking.

Can UV lasers mark metal?

They can mark metal, but fiber lasers are more efficient for that purpose.

Are laser marks permanent?

Yes. Laser engraving creates physical changes in the material, producing indelible marks resistant to wear and weather.

How often should a laser marker be serviced?

Fiber lasers need minimal maintenance. CO₂ systems require mirror and tube replacement about annually. UV and DPSS systems require optical alignment checks from time to time.

Can lasers mark curved surfaces?

Absolutely. With a rotary accessory or proper fixturing and software compensation, lasers handle curved parts well.

Can a single laser marking machine type handle multiple materials?

Some fiber lasers and UV lasers offer enough flexibility to switch materials quickly through software settings, but CO₂ lasers still perform best on organic materials.