Electric Vehicle Battery Welding: Copper and Aluminum Connections

Table of Contents

In the production of electric vehicle batteries, welding technology plays a crucial role, especially when it comes to electric vehicle battery welding, where the connection of copper and aluminum is seen as a technical challenge. As the electric vehicle industry rapidly grows, the performance and safety of batteries have become a focal point, and welding processes directly affect the overall quality of the battery modules.

Electric vehicle battery welding is not just about simply connecting materials; it involves complex technical challenges and innovative methods. In this article, we will explore the application of copper and aluminum in electric vehicle batteries and their welding processes, analyzing how the combination of these two materials impacts battery efficiency, lifespan, and safety.

Copper and Aluminum in Electric Vehicle Batteries

One of the key materials in electric vehicle batteries is copper and aluminum, which serve critical roles in conducting electricity within the battery. Copper is typically used for battery connectors, electrodes, and the connections between battery modules due to its excellent conductivity, while aluminum, known for its lightweight properties and adequate conductivity, is used in other components of the battery.

The key to copper and aluminum welding lies in the physical differences between these two metals: copper offers superior conductivity, and aluminum is lighter. Effectively and stably welding these two materials together is a technical challenge in battery manufacturing.

Key Challenges in Copper and Aluminum Welding

1.Welding Defects: The significant difference in the thermal expansion coefficients between copper and aluminum can lead to cracks or insufficient weld strength. Especially in the high-load working environments of electric vehicle batteries, the stability of the welded joints is critical for battery safety.

2.Method Selection: Common welding methods for copper and aluminum welding include laser welding, friction welding, and ultrasonic welding. Each method has its pros and cons, and choosing the right welding process is crucial. Laser welding can precisely control heat input, while friction welding minimizes the heat-affected zone, effectively reducing material deformation and cracks.

3.Distortion Control: Due to the thermal expansion differences between copper and aluminum, distortion is a common problem. Through proper welding process parameters and heat management, distortion can be minimized, ensuring the stability and strength of the welded joints.

Advanced Techniques in Electric Vehicle Battery Welding

With the advancement of welding technology, electric vehicle battery welding has gradually become more intelligent and efficient. Emerging welding techniques like laser welding and friction welding are widely used in electric vehicle battery production.

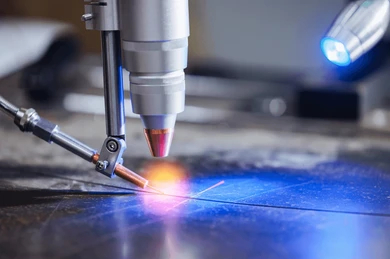

1.Laser Welding: Laser welding is a precise, high-efficiency welding method ideal for copper and aluminum welding. The laser beam can precisely focus on the welding area, controlling heat input and preventing excessive heat from affecting the weld. The advantage of laser welding is its ability to produce uniform welds, suitable for mass production.

2.Friction Welding: Friction welding is a process that uses rotational and pressure combination methods to achieve welding. It has a low heat-affected zone, effectively reducing issues like thermal cracking in copper and aluminum welding. Friction welding is widely used for high-strength welding joints, especially for copper-aluminum connections in battery modules.

3.Smart Welding Technologies: With the rise of smart manufacturing, electric vehicle battery welding is becoming more automated and intelligent. Through real-time data collection and analysis, smart welding systems can automatically adjust welding parameters, ensuring better weld quality, higher efficiency, and reduced human error.

Welding Procedure Qualification and Nondestructive Testing

In electric vehicle battery welding, ensuring the quality of the weld is crucial. To ensure the strength and stability of the weld joints, a welding procedure qualification (WPQ) is essential before welding. WPQ typically involves testing different welding techniques and parameters to ensure the chosen welding method meets the structural requirements.

At the same time, nondestructive testing (NDT) is an important step in electric vehicle battery welding. Common NDT methods include ultrasonic testing, X-ray inspection, and electromagnetic testing. These tests ensure that the welded joints are free from internal defects, such as cracks or voids, preventing battery malfunctions or safety risks.

Conclusion: Innovation in Electric Vehicle Battery Welding

With the growing demand for electric vehicles, the need for efficient and high-quality electric vehicle battery welding becomes increasingly important. As welding technology continues to evolve, techniques like laser welding and friction welding will further improve weld quality, and welding processes will become more precise and efficient. The future of electric vehicle battery welding lies in smarter, more automated systems that enhance precision and efficiency, meeting the higher quality requirements for electric vehicle batteries.

To learn more about electric vehicle battery welding and related technologies, click here to [explore further insights into welding techniques].