Desktop vs Handheld Laser Marking Systems

Table of Contents

Introduction

In modern manufacturing and product identification, laser marking systems have become indispensable tools for ensuring quality, traceability, and brand identity. As industries continue to automate production, choosing between desktop laser marking machines and handheld laser marking systems has become a critical decision for businesses. Each system type offers unique benefits in terms of precision, flexibility, portability, and space efficiency. Understanding their strengths and limitations helps manufacturers select the most effective solution for their production goals.

Understanding Laser Marking Systems

What Are Laser Marking Systems?

Laser marking systems use focused laser beams to create permanent markings on a variety of materials, such as metal, plastic, and ceramics. These markings include serial numbers, QR codes, barcodes, and logos used for identification and traceability.

The performance of a laser marking system depends on three key factors:

- Laser type (fiber, CO2, or UV)

- Optical system stability

- Motion and focusing precision

Desktop vs Handheld Laser Configurations

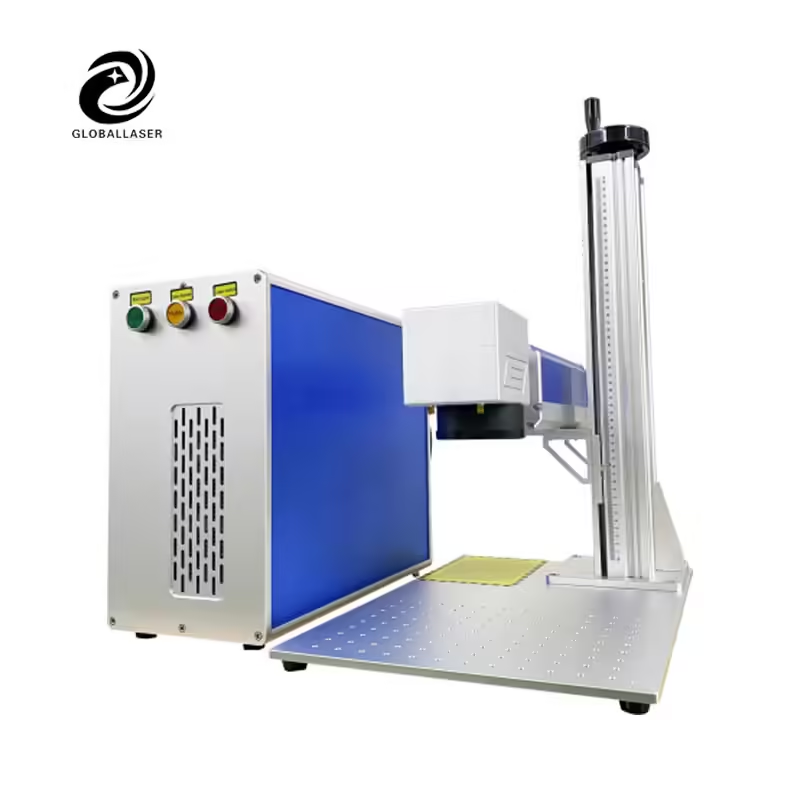

Desktop laser marking systems are compact, stable, and ideal for high-precision work such as marking electronic parts, medical instruments, or small tools. In contrast, handheld laser marking systems and large-format models provide flexibility for marking oversized or immovable parts, making them essential for industries like automotive, aerospace, and heavy equipment manufacturing.

To make an informed decision, manufacturers should analyze performance, accuracy, cost, and space utilization.

Technical Comparison Between Desktop and Handheld Systems

Design and Construction

Desktop laser marking systems typically feature enclosed structures, integrated worktables, and stable optical configurations. They provide superior vibration resistance, enabling micron-level precision for detailed engravings, serial numbers, QR codes, and micro-text. Their enclosed design also improves user safety and fume extraction. Most desktop laser marking machines employ fiber laser or UV laser sources, which produce sharp, high-contrast marks on metals, plastics, and coated materials. These laser marking systems can operate continuously with minimal calibration, making them ideal for cleanroom or laboratory environments.

In contrast, handheld and large-scale laser marking systems are designed for flexibility. They feature a portable marking head connected via optical fiber to the laser source. This configuration allows operators to mark large, heavy, or irregularly shaped parts that cannot be moved easily. Handheld laser marking systems are often used for direct part marking in automotive plants, construction machinery workshops, and large equipment maintenance.

Comparative Technical Specifications

| Parameter | Desktop Laser Marking System | Handheld / Large Laser Marking System |

|---|---|---|

| Precision | Very high (±0.01 mm) | Moderate (±0.05 mm typical) |

| Work Area | Limited (100×100 mm typical) | Large or variable (up to several meters) |

| Portability | Fixed unit | Highly portable and flexible |

| Speed | Fast (up to 7000 mm/s) | Operator-dependent |

| Ease of Use | Automated and user-friendly | Requires manual alignment |

| Safety | Enclosed and filtered | Open operation with safety measures |

| Cost | Moderate | Higher for large or industrial models |

| Ideal Use | Small parts, precision marking | Large components, on-site marking |

Performance and Application Comparison

Precision and Quality

Precision is the most significant differentiator between the two types of laser marking systems. Desktop machines are optimized for applications that require tight tolerances and consistent quality. They deliver sharp engraving depth, uniform contrast, and fine beam focus. These systems are especially favored in electronics, jewelry, and medical industries, where marking detail is paramount. Desktop laser marking systems also integrate easily with vision alignment and automated conveyors for high-throughput production.

Versatility and Industrial Applications

Handheld laser marking systems, while slightly less precise, excel in versatility. They can operate in warehouses, outdoor environments, or directly on assembly lines without moving large components. Their mobility dramatically reduces handling time and production downtime.

In automotive manufacturing, for example, handheld fiber laser marking systems are used to mark chassis plates, engine blocks, and gear housings. For energy and infrastructure applications, they can engrave serial numbers, compliance marks, and barcodes on pipes, beams, and panels — directly at the installation site.

Operational Efficiency and Cost Analysis

Stability and Performance

From a performance standpoint, desktop laser marking systems maintain stable beam quality through fixed optics and isolated work chambers, ensuring constant focal distance and minimal vibration interference. Handheld laser marking systems rely more on operator steadiness, though recent advancements in smart focus, gyroscopic stabilization, and visual alignment have narrowed the gap in quality.

Cost Efficiency and ROI

When it comes to cost, desktop laser marking machines are generally more economical for small to medium-scale production. They consume less power, occupy limited floor space, and require minimal maintenance. Handheld laser marking systems often have higher initial costs but offer faster ROI in industries that benefit from mobility and flexibility.

For example, repair and maintenance workshops can mark products in place without disassembling large machinery, significantly reducing labor hours.

Space Efficiency and Workplace Integration

Space efficiency is another critical factor. Desktop laser marking systems are highly space-efficient — typically requiring less than one square meter of workspace. They are perfect for laboratories, compact factories, or multi-station production cells.

In contrast, handheld or large-scale laser marking systems need more open workspace but can handle tasks that smaller models cannot, making them indispensable in heavy industry and fieldwork scenarios.

Choosing the Right Laser Marking System

When evaluating both laser marking systems, several factors must be considered:

| Decision Factor | Recommended System |

|---|---|

| Small parts, fine detail | Desktop Laser |

| Large or fixed parts | Handheld Laser |

| Limited workspace | Desktop Laser |

| On-site operations | Handheld Laser |

| Cleanroom marking | Desktop Laser |

| Automotive or heavy industry | Handheld Laser |

Key Selection Criteria

- Part Size and Material: Desktop machines are best for small to medium parts; handheld units suit large or heavy components.

- Work Environment: Cleanrooms or fixed stations favor desktop systems; mobile or on-site work requires handheld models.

- Production Volume: High-volume, repetitive marking benefits from desktop automation; low-volume, diverse marking suits handheld systems.

- Budget and ROI: Desktop units are cost-efficient for small businesses; handheld systems maximize ROI in flexible, large-scale operations.

- Safety and Compliance: Enclosed desktop designs meet stricter safety standards, while handheld units need additional PPE and protective zones.

Conclusion

In conclusion, both desktop and handheld laser marking systems serve critical roles in modern manufacturing. Desktop models offer unmatched accuracy, consistency, and space efficiency — perfect for fine-detail engraving and continuous production. Handheld laser marking systems deliver mobility, adaptability, and ease of use for large, complex, or on-site applications. The right choice depends on your production priorities: precision versus flexibility, workspace constraints, and desired ROI. By aligning your laser marking system investment with operational goals, you ensure long-term efficiency, compliance, and competitiveness in an increasingly automated industrial landscape.

FAQ

What type of laser is used in most desktop laser marking systems?

Fiber and UV lasers are the most common. They deliver high precision, fast marking speeds, and excellent contrast on metals and plastics.

Can handheld laser marking systems match the precision of desktop models?

While not fully equal, modern handheld systems use intelligent focus and visual alignment to achieve near-desktop quality for industrial applications.

Are desktop laser marking systems suitable for mass production?

Yes. Many manufacturers deploy multiple desktop units simultaneously or integrate them into conveyor systems for automated marking.

What safety precautions should be taken for handheld laser marking systems?

Operators must use certified safety goggles, maintain a clear safety perimeter, and ensure proper ventilation during operation.

Which system provides a better long-term return on investment?

It depends on your needs. Desktop laser marking systems provide lower maintenance and higher precision, while handheld systems deliver flexibility and on-site capability, ideal for large or irregular parts.