Master Precision with Fiber Laser Marking Machines

Table of Contents

Introduction

In today’s fast-evolving manufacturing landscape, accuracy, efficiency, and reliability are no longer luxuries—they’re expectations. Whether you’re producing automotive components, electronic parts, or high-end tools, precision marking is an essential step in maintaining traceability, quality assurance, and brand identity.

Among all marking technologies, one stands out for its exceptional performance and adaptability: the fiber laser marking machine. This innovative system is transforming how industries approach product marking, offering unmatched precision, long-lasting results, and impressive cost efficiency.

If you’re searching for a way to upgrade your marking process or modernize your production line, understanding the fiber laser marking machine and its advantages is the perfect place to start.

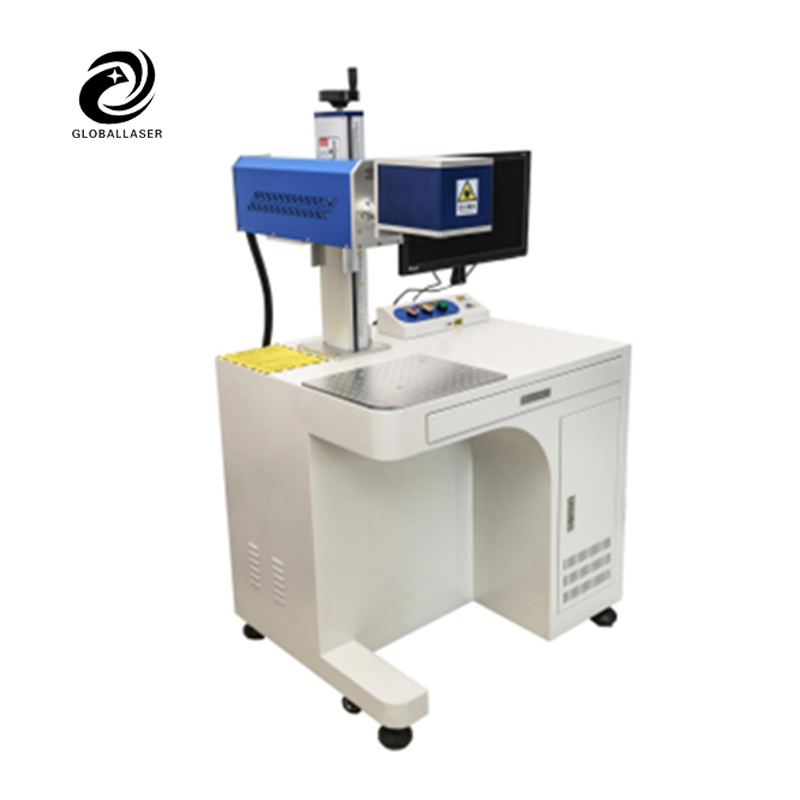

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine is an advanced laser system that uses a high-powered beam generated through fiber optics to permanently mark materials such as metals, plastics, and ceramics. Unlike ink-based or mechanical marking methods, fiber laser technology delivers non-contact, chemical-free engraving that doesn’t fade, wear, or damage the surface.

According to a 2024 report from Laser Technology Insights, fiber laser machines now account for over 60% of global industrial marking applications due to their durability, low maintenance, and adaptability.

Why Fiber Laser Marking Machines Are the Industry Standard

1. Unparalleled Precision and Clarity

The laser beam diameter can be as fine as 0.01mm, allowing extremely detailed text, barcodes, and micro-patterns. Whether you need to engrave a serial number on a steel component or a microcode on an electronic part, the results are sharp and consistent.

2. Long-Term Reliability

Fiber laser systems can operate for over 100,000 hours with minimal maintenance. This makes them ideal for factories running continuous production lines that demand long-term stability and consistent output.

3. Wide Material Compatibility

One of the biggest advantages of a fiber laser marking machine is its ability to work on a wide range of materials:

- Metals: Stainless steel, aluminum, copper, brass, titanium

- Non-metals: ABS plastic, PBT, polycarbonate, coated materials

- Specialty surfaces: Anodized metal, ceramics, and composites

4. Eco-Friendly and Maintenance-Free Operation

Unlike inkjet or chemical etching, fiber laser marking does not require solvents, consumables, or replacement parts. It’s an environmentally responsible solution that helps reduce operational waste and improve workplace safety.

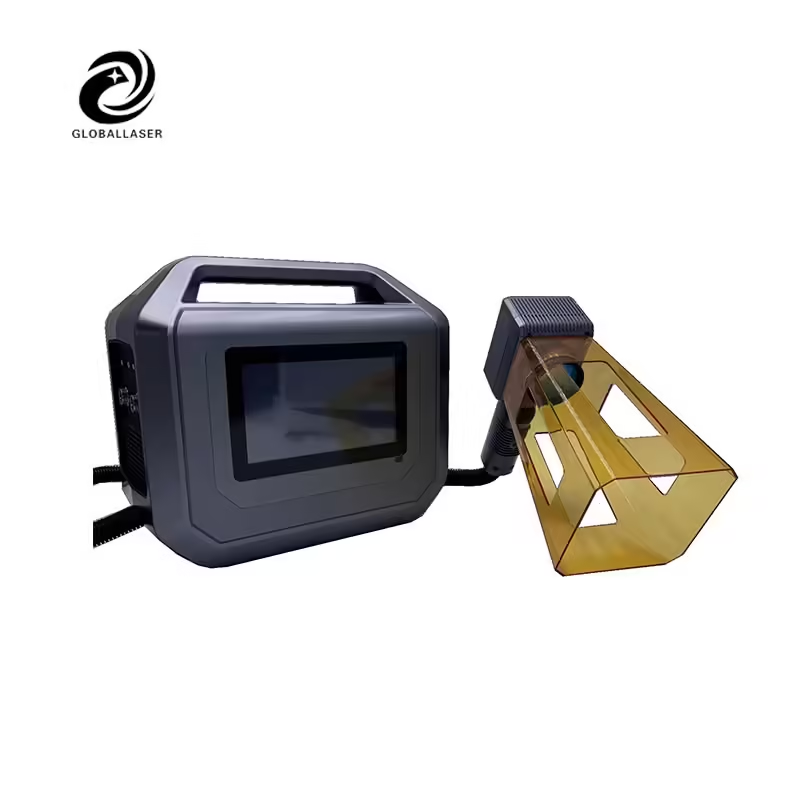

5. Automation and Integration Ready

Modern fiber laser systems are compatible with automation platforms, allowing easy integration with conveyor belts, robotic arms, and factory management software. This adaptability is a key advantage in smart manufacturing and Industry 4.0 environments.

Fiber Laser Marking Machine Technical Highlights

| Feature | Description | Benefits |

|---|---|---|

| Laser Power | 20W–100W fiber laser source | Suits both light and deep marking |

| Beam Diameter | 0.01–0.03 mm | High-precision engraving |

| Lifespan | Up to 100,000 hours | Long-term industrial use |

| Cooling System | Air-cooled | No additional chiller needed |

| Control Software | EZCAD or custom-developed systems | User-friendly and automation-ready |

| Material Support | Metal, plastic, ceramic, coated surfaces | Versatile across industries |

These technical specifications demonstrate why fiber laser machines are not just tools—but long-term investments in manufacturing efficiency.

Applications Across Industries

Automotive and Aerospace

Used for marking engine parts, identification codes, and safety information that must remain legible under extreme conditions.

Electronics and Semiconductor Manufacturing

Essential for high-density, low-heat marking on PCBs, chips, connectors, and housings. Fiber lasers ensure legibility without damaging sensitive components.

Medical Equipment and Instruments

Perfect for creating sterilization-resistant marks on surgical instruments, implants, and lab tools—essential for regulatory compliance and traceability.

Jewelry and Personalization

Delivers intricate, artistic engravings on metals and fine surfaces, ideal for brand logos, serial numbers, and custom patterns.

Industrial Tools and Hardware

Marking permanent part numbers, QR codes, or company branding for traceability and anti-counterfeiting.

Packaging and Consumer Goods

Laser-engraved logos and date codes enhance brand visibility while ensuring durability and tamper resistance.

Comparing Fiber Laser Marking Machines with Other Technologies

| Technology | Precision | Maintenance | Speed | Suitable Materials | Lifespan |

|---|---|---|---|---|---|

| Fiber Laser | Excellent | Very Low | Very Fast | Metals, Plastics | 10+ years |

| CO₂ Laser | Good | Moderate | Medium | Wood, Leather, Acrylic | 5–7 years |

| UV Laser | Excellent | Low | Medium | Glass, Polymer | 8–10 years |

| Inkjet Marking | Poor | High | Medium | Limited | 2–3 years |

As seen above, fiber laser marking consistently outperforms other marking technologies in precision, longevity, and versatility.

Key Factors to Consider Before Choosing a Fiber Laser Marking Machine

Material Type

Different materials require different laser wavelengths and power levels. Fiber lasers are perfect for metals, while UV lasers may suit glass or delicate polymers.

Marking Depth and Contrast

If your products require deep engraving or dark contrast marks, choose higher wattage (30W–50W) and pulse control systems such as MOPA fiber lasers.

Production Volume

For continuous, automated marking, an inline or industrial-grade fiber laser system is recommended.

Software and Connectivity

Look for systems that support design formats (DXF, PLT, AI) and can connect to automation systems or barcode scanners.

Supplier Credibility

Choose experienced manufacturers with international certifications (CE, ISO) and strong after-sales service records.

Maintenance and Operational Tips

To maintain stable performance and extend your fiber laser’s lifespan:

- Keep the optical lens and mirror clean from dust and oil.

- Operate within recommended temperature and humidity levels.

- Avoid power surges by using a regulated power supply.

- Update software periodically to maintain marking accuracy.

- Schedule preventive checks to ensure beam alignment.

Conclusion

The fiber laser marking machine represents the perfect fusion of innovation, precision, and efficiency. From small workshops to large-scale factories, it enables manufacturers to achieve flawless, permanent markings that stand the test of time.

With its unmatched durability, compatibility, and automation potential, fiber laser technology is redefining industrial marking standards across the globe.

If you’re ready to enhance your production efficiency, strengthen your brand identity, and future-proof your manufacturing line, contact us today for expert guidance and customized laser marking solutions.

FAQ

What makes fiber lasers different from CO₂ or UV lasers?

Fiber lasers use a solid-state source with optical fiber amplification, offering higher efficiency and precision for metals.

Can I use the same machine for plastics and metals?

Yes, though results vary. For multi-material use, MOPA fiber lasers provide more control over pulse duration and energy.

Is it difficult to operate?

Not at all. Most machines feature intuitive software interfaces that allow new users to start marking within hours.

How long can the laser operate continuously?

Industrial-grade models can run 24/7 with proper ventilation and cooling.

Does fiber laser marking fade over time?

No. The process alters the material surface structure, ensuring permanent, fade-resistant markings.