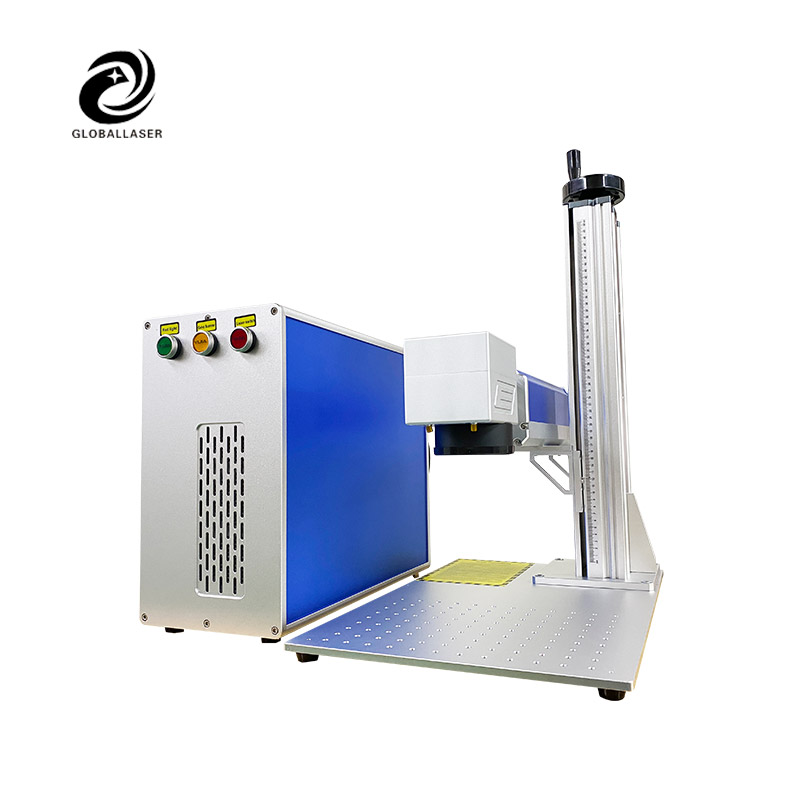

Fiber Laser Marking Machines for High-Speed Engraving

Table of Contents

Introduction

In the fast-moving world of manufacturing, precision and durability are everything. Whether you’re engraving stainless steel parts, marking serial numbers on tools, or creating permanent brand logos on products, you need a machine that delivers accuracy, speed, and consistency. That’s exactly where the fiber laser marking machine shines.

A fiber laser marking machine has become the gold standard for industrial metal engraving. Known for its fine beam quality, high energy efficiency, and long service life, this technology is now widely used across multiple industries—from automotive and aerospace to electronics and medical device manufacturing.

If you’re searching for a long-lasting, cost-effective solution to upgrade your marking process, understanding the power of fiber laser technology is the first step.

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine uses a high-intensity laser beam generated by optical fiber cables doped with rare-earth elements such as ytterbium. This beam interacts with the surface of a material to create permanent, high-contrast marks without using ink, chemicals, or physical contact.

Unlike traditional marking methods such as mechanical engraving or inkjet printing, fiber laser marking ensures:

- Zero consumables

- Minimal maintenance

- Non-contact precision

- Long-term stability and consistency

According to a report by MarketsandMarkets (2024), the global fiber laser market is expected to grow at a CAGR of 8.5% through 2030, mainly driven by the demand for traceability, product branding, and industrial automation.

Key Advantages of Fiber Laser Marking Machines

Fiber laser technology offers several compelling benefits that make it the preferred choice for modern factories.

1. Unmatched Marking Quality

With a beam diameter as small as 0.01mm, the machine delivers crisp, clean, and precise marks even on the tiniest surfaces.

2. Long Service Life

The average fiber laser source lasts more than 100,000 working hours, meaning you can run it for over 10 years with minimal maintenance.

3. High Efficiency

Fiber lasers convert up to 40% of electrical energy into laser output, making them more energy-efficient than CO₂ or diode systems.

4. Wide Material Compatibility

From stainless steel, aluminum, and brass to titanium, copper, and certain plastics — the fiber laser marking machine works with nearly any metal-based surface.

5. Cost-Effective and Eco-Friendly

No need for inks or solvents. Fiber laser marking reduces waste, lowers operational costs, and minimizes environmental impact.

6. Easy Integration with Automation

These systems can seamlessly integrate with conveyors, robots, and production lines for continuous marking in industrial environments.

Comparison Table: Fiber Laser vs. Other Marking Machines

| Feature | Fiber Laser Marking Machine | CO₂ Laser Engraver | Inkjet Marker |

|---|---|---|---|

| Marking Precision | ±0.01 mm | ±0.05 mm | ±0.2 mm |

| Speed | 8,000–10,000 mm/s | 3,000–5,000 mm/s | 1,000–2,000 mm/s |

| Lifespan | 100,000+ hours | 30,000–40,000 hours | 5,000 hours |

| Material Compatibility | Metal, Plastic, Ceramic | Wood, Leather, Acrylic | Paper, Plastic |

| Maintenance | Very low | Moderate | High |

| Consumables | None | None | Ink cartridges |

| Energy Efficiency | Excellent | Average | Poor |

This table clearly shows why more manufacturers are switching to fiber laser technology — it’s faster, cleaner, and more reliable.

Applications of Fiber Laser Marking Machines

The versatility of fiber laser technology allows it to serve a wide range of industries:

1. Automotive and Aerospace

Used for engraving VINs, component IDs, and metal labels that must withstand extreme conditions.

2. Electronics and Semiconductors

Ideal for micro-marking on connectors, chips, and PCBs where precision and low thermal impact are critical.

3. Medical Devices

Creates sterilization-resistant marks for surgical instruments, implants, and lab equipment.

4. Metal Fabrication

Used in cutting, engraving, and marking metal parts for tool production and construction hardware.

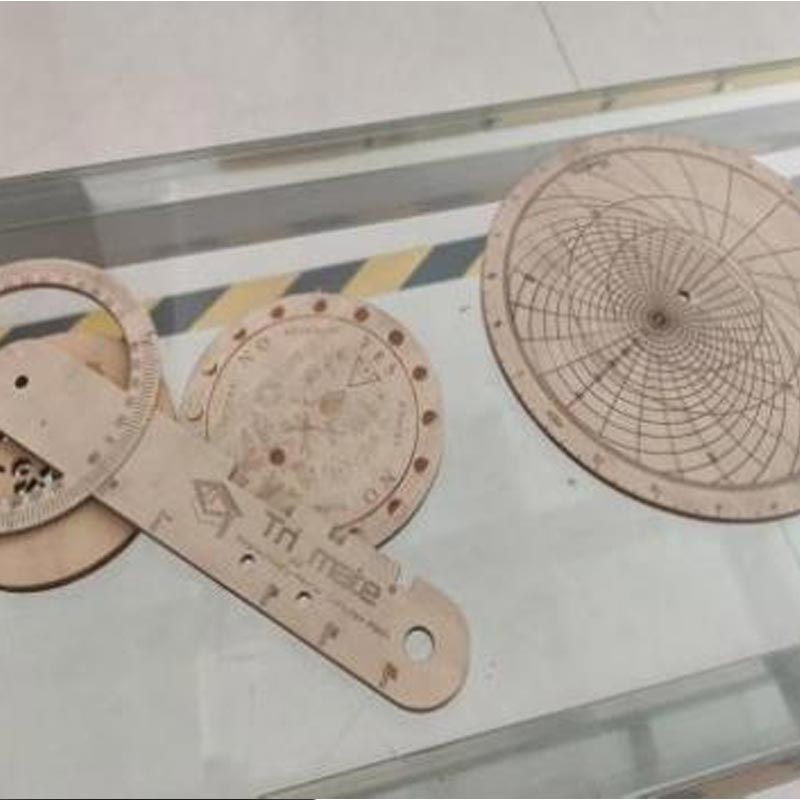

5. Jewelry and Craft Design

Delivers smooth, aesthetic engravings for logos, serial numbers, and patterns on gold, silver, and stainless steel jewelry.

6. Industrial Automation

Integrated with robotic systems for high-volume marking in smart manufacturing environments.

How to Choose the Right Fiber Laser Marking Machine

Selecting the right model depends on your materials, marking depth, and production goals.

| Application | Recommended Power | Suggested Model Type | Features |

|---|---|---|---|

| Fine Engraving on Metal | 20W | Desktop Fiber Laser Marker | Compact, high precision |

| Industrial Deep Marking | 30W–50W | Floor-standing Model | High-speed, durable |

| Plastic or Coated Surfaces | 20W | MOPA Fiber Laser | Adjustable pulse for better color contrast |

| Mobile or Outdoor Use | 30W Handheld Model | Portable Fiber Marker | Lightweight and flexible |

| Automated Production | 50W+ | Inline Fiber Laser Marker | Integrates with conveyor and robotics |

When choosing your machine, always consider:

- Your daily production volume

- Material types and marking depth

- Software compatibility

- Cooling system (air or water)

- After-sales service and warranty

Maintenance and Operation Tips

To extend the lifespan of your fiber laser marking machine:

- Keep the lens clean and dust-free.

- Ensure a stable power supply voltage.

- Regularly check the cooling fan and air circulation.

- Avoid direct contact with the laser beam.

- Back up marking files periodically.

Proper maintenance ensures continuous high performance and reduces unexpected downtime.

Conclusion

The fiber laser marking machine represents the future of industrial marking — precise, durable, and environmentally friendly. From metal part engraving to automated production marking, this technology delivers consistent performance and excellent return on investment.

If you want to elevate your production efficiency, enhance your brand identity, and minimize operational costs, now is the time to invest in a high-quality fiber laser marking machine.

Contact us today to get expert advice, a free quote, and customized laser marking solutions for your business.

FAQ

What materials can a fiber laser marking machine engrave?

It can mark metals such as stainless steel, brass, copper, titanium, aluminum, and some plastics.

Is it suitable for high-volume production?

Yes, fiber lasers are designed for 24/7 industrial operation and are compatible with automation lines.

Can I use it for color engraving?

With MOPA fiber laser models, you can produce colorful marks on stainless steel and titanium.

How much does a fiber laser marking machine cost?

Prices typically range from $3,000 to $12,000, depending on power, configuration, and features.

What kind of maintenance does it require?

Minimal maintenance — just regular lens cleaning and software updates. No consumables needed.