Why the Fiber Laser Marking Machine is Essential for Modern Industry

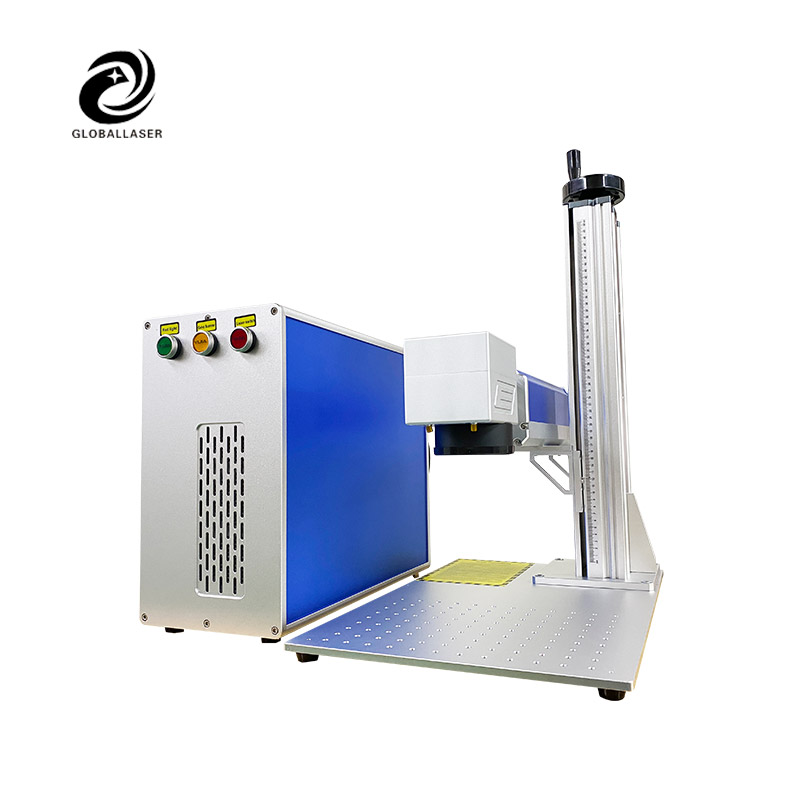

Welcome to the forefront of manufacturing technology, where precision, speed, and durability are non-negotiable standards. If your operation demands high-quality, permanent coding on industrial materials, you are looking for more than just an engraver—you need a Fiber Laser Marking Machine. As an integrated international manufacturer specializing in comprehensive laser equipment and processing solutions, SDGlobal Laser recognizes that the right technology is the fundamental driver of industrial upgrading. A fiber laser marker doesn’t just apply a mark; it embeds efficiency and longevity directly into your product line.

We are committed to providing customers with high-quality and cost-effective laser processing solutions. The fiber laser marker machine stands out among our core offerings, which cover multiple series, including laser cutting machines, laser engraving machines, and laser welding machines. By leveraging over 10 years of experience in the laser industry and a commitment to research, development, and innovation, we engineer equipment designed to create industry benchmarks, underpinned by over 20 invention patents.

Table of Contents

Understanding the Technological Superiority of Fiber Lasers

The term “Fiber Laser Marking Machine” refers to a specific type of laser system that utilizes an optical fiber doped with rare-earth elements as the gain medium. This core technology provides several inherent advantages over other marking methods. While SDGlobal Laser offers a wide variety of marking solutions—including CO2 Laser Marking Machines, UV Laser Marking Machines, Flying Laser Marking Machines, and Vision Laser Marking Machines—the fiber laser is specifically renowned for its exceptional beam quality and energy efficiency, making it the superior choice for deep, durable marking on robust materials.

Core Benefits: Driving Efficiency Through Speed and Durability

The global recognition of the fiber laser marking machine is directly linked to its capacity to solve critical production challenges, especially concerning speed and material compatibility.

High-Speed Production Optimization

In fast-paced manufacturing environments, bottlenecks in marking or coding can severely impact throughput. The efficiency of the fiber laser system is a significant advantage. This machine is designed for continuous, high-speed operation, which is why it is featured as a key topic when discussing how to improve cable tray production efficiency. By applying durable marks rapidly, manufacturers can optimize their overall production flow without sacrificing mark quality. The high repetition rate and fast galvanometer system allow for quick marking of complex data, such as serial numbers, barcodes, and logos, across thousands of parts per shift. This speed translates directly into reduced labor costs and increased manufacturing capacity, empowering smart production worldwide.

Unlocking Precision on Metal Surfaces

One of the most defining applications for the fiber laser marking machine is the marking of metals. Traditional marking methods often struggle with hard alloys, resulting in shallow or inconsistent marks. However, the energy density achievable with a focused fiber laser beam is ideal for creating deep, dark, and highly precise engravings on metal surfaces.

This capability is critical for sectors like the automotive industry and general industrial parts supply, where permanent identification is mandated for quality control and safety. Exploring how a laser marking machine for metal boosts precision, durability, and efficiency in industrial applications underscores its essential role in metal processing. The Standard Handheld Marking Machine, which often utilizes fiber technology, is, for instance, a trusted piece of equipment for Industrial Parts Suppliers.

Versatility Across a Spectrum of Materials

While its performance on metal is exceptional, the fiber laser marking machine is also versatile enough to handle a range of non-metallic materials, albeit often used primarily where high power and deep marking are required. SDGlobal Laser’s core business focuses on equipment used across many fields, demonstrating the broad application of this technology, including:

1. Electronic Appliances: Achieving the micro-precision needed for components that are often sensitive or extremely small.

2. Auto Parts: Ensuring permanent, reliable coding for vital components necessary for vehicle safety and traceability.

3. Medical Equipment: Producing clean, non-contaminating, and permanent marks on tools and devices that require sterilization.

4. Craft Gifts and Advertising Art: Offering the detailed capability required for aesthetic customization and specialized artistic projects.

5. Home Decoration and Clothing/Leather: Providing specialized marking solutions for textiles and home goods.

This vast applicability shows that whether you are an Electronic Component Manufacturer relying on a Vision Laser Marking Machine for alignment or an Advertising Craft Business Owner utilizing a Separate Fiber Laser Marking Machine, laser marking technology is fundamentally integrated into modern production.

Tailoring the Solution: Finding the Right Laser Marking Equipment

Choosing the optimal laser processing solution depends heavily on your specific environment, material, and required marking speed. SDGlobal Laser provides several variants of laser marking machines, each designed to meet unique operational demands:

| Machine Type | Key Characteristics and Environment | Primary Benefits | Typical Customer/Application Reference |

| Fiber Laser Marking Machine (General) | High-power, solid-state laser; ideal for deep or high-speed marking. | Exceptional precision, unmatched durability, high throughput. | Metal part manufacturers, Cable tray production. |

| Separate Fiber Laser Marking Machine | Modular design, often allowing for easier integration or transport. | Flexibility, ease of use in diverse settings. | Advertising Craft Business Owner. |

| Desktop Laser Marking Machine | Compact footprint, optimized for environments with limited space. | Perfect blend of performance and space efficiency. | Small-scale production, workshops. |

| Cabinet Laser Marking Machine | Fully enclosed industrial design, robust and stable. | Safety, robustness, integrated system design. | General Industrial Manufacturing. |

| Vision Laser Marking Machine | Integrates advanced camera systems for automatic alignment and recognition. | Extreme precision on micro-components, essential for electronics. | Electronic Component Manufacturers. |

| UV Laser Marking Machine | Utilizes a ‘cold’ marking process. | Ideal for sensitive materials that cannot tolerate heat, ensuring precision and durability. | Sensitive materials, specific plastics. |

This wide array of offerings ensures that we can provide customized, cost-effective laser processing solutions designed to meet the personalized needs of customers, including flexible cooperation modes like OEM/ODM services.

Conclusion

The integration of a Fiber Laser Marking Machine into your manufacturing process is a powerful leap forward, guaranteeing permanent, high-speed, and precise identification crucial for industrial accountability and product longevity. By partnering with an internationally recognized manufacturer like SDGlobal Laser, which combines extensive experience, proprietary patents, and stringent quality control, you gain access to high-quality and cost-effective laser processing solutions.

Whether your goal is to enhance the marking durability of auto parts, achieve micro-precision on electronic components, or dramatically boost efficiency in cable tray production, the fiber laser marker is the definitive choice for modern industrial upgrading. Choose technical strength, choose reliability, choose SDGlobal Laser to empower your smart production worldwide.

FAQ

What is the primary advantage of a Fiber Laser Marking Machine over other types?

The fiber laser marker machine’s primary advantages are its exceptional speed and durability. It significantly boosts precision and efficiency, especially in industrial applications involving metal marking.

In which specific fields are your laser marking machines widely used?

Our laser equipment, including fiber markers, is widely used in multiple fields. These include, but are not limited to, clothing and leather, advertising art, craft gifts, electronic appliances, home decoration, medical equipment, and auto parts.

Does SDGlobal Laser offer solutions for smaller operations or customized needs?

es, we offer solutions like the Desktop Laser Marking Machine, which provides a perfect blend of performance and space efficiency. Additionally, we provide OEM/ODM services to meet the personalized needs of all customers.

How is the reliability of the marking equipment ensured before delivery?

High quality and reliability are guaranteed because each piece of equipment undergoes strict quality tests before leaving the factory to ensure optimal performance. Our commitment is backed by over 10 years of experience and 20+ invention patents.

Besides fiber markers, what other types of laser marking machines do you manufacture?

SDGlobal Laser manufactures a comprehensive range of laser marking machines, including CO2 Laser Marking Machines, UV Laser Marking Machines, Flying Laser Marking Machines, and Vision Laser Marking Machines.

If I encounter an operational issue, what kind of support is provided?

We provide excellent customer support, including 24/7 round-the-clock service. This dedicated support covers technical consultation, product training, and extensive after-sales service.